Rare earth oxide grinding machine capable of achieving automatic discharge

A technology of rare earth oxides and automatic feeding, which is applied in grain processing and other fields, and can solve the problems of labor-saving grinding and crushing under airtight conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

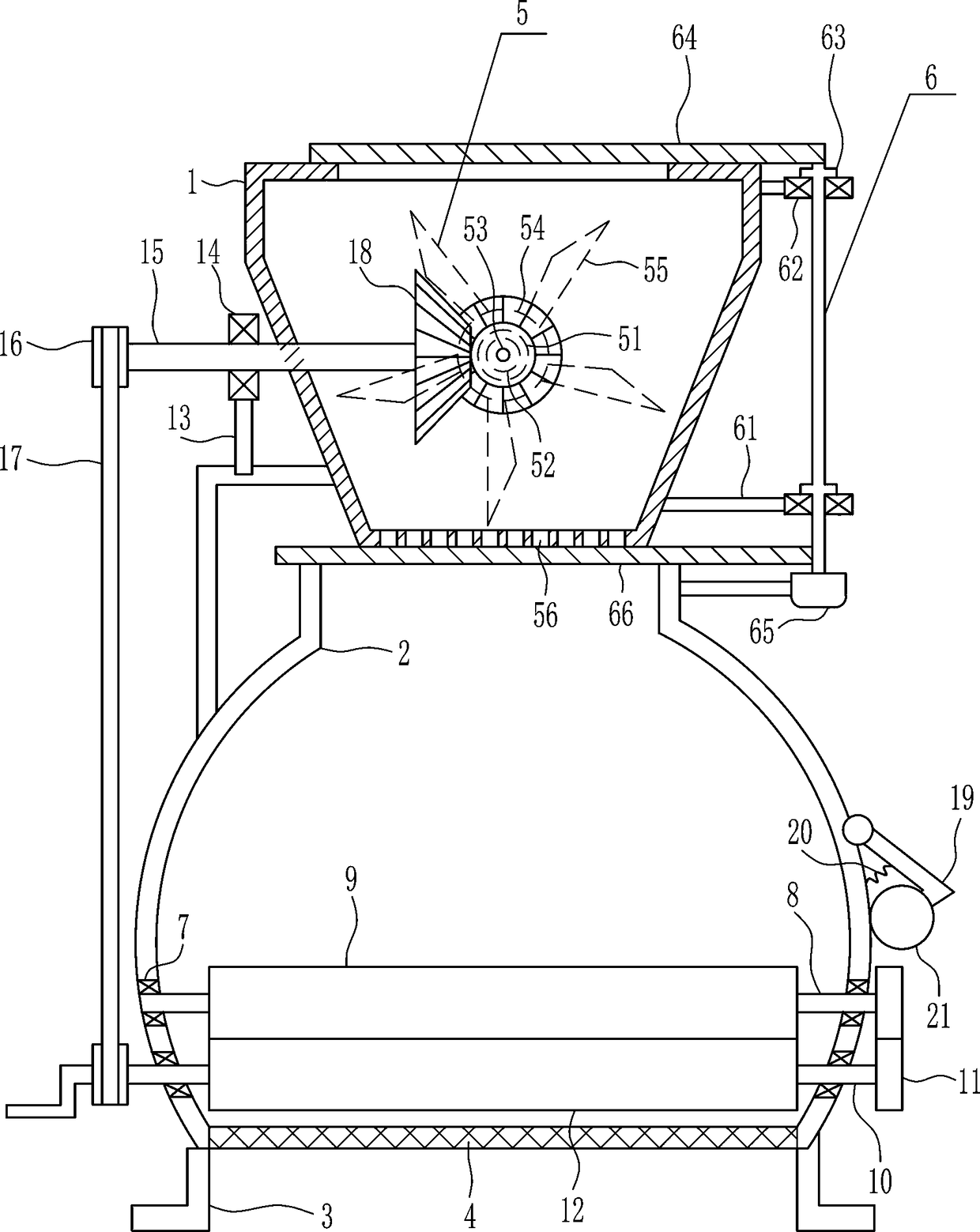

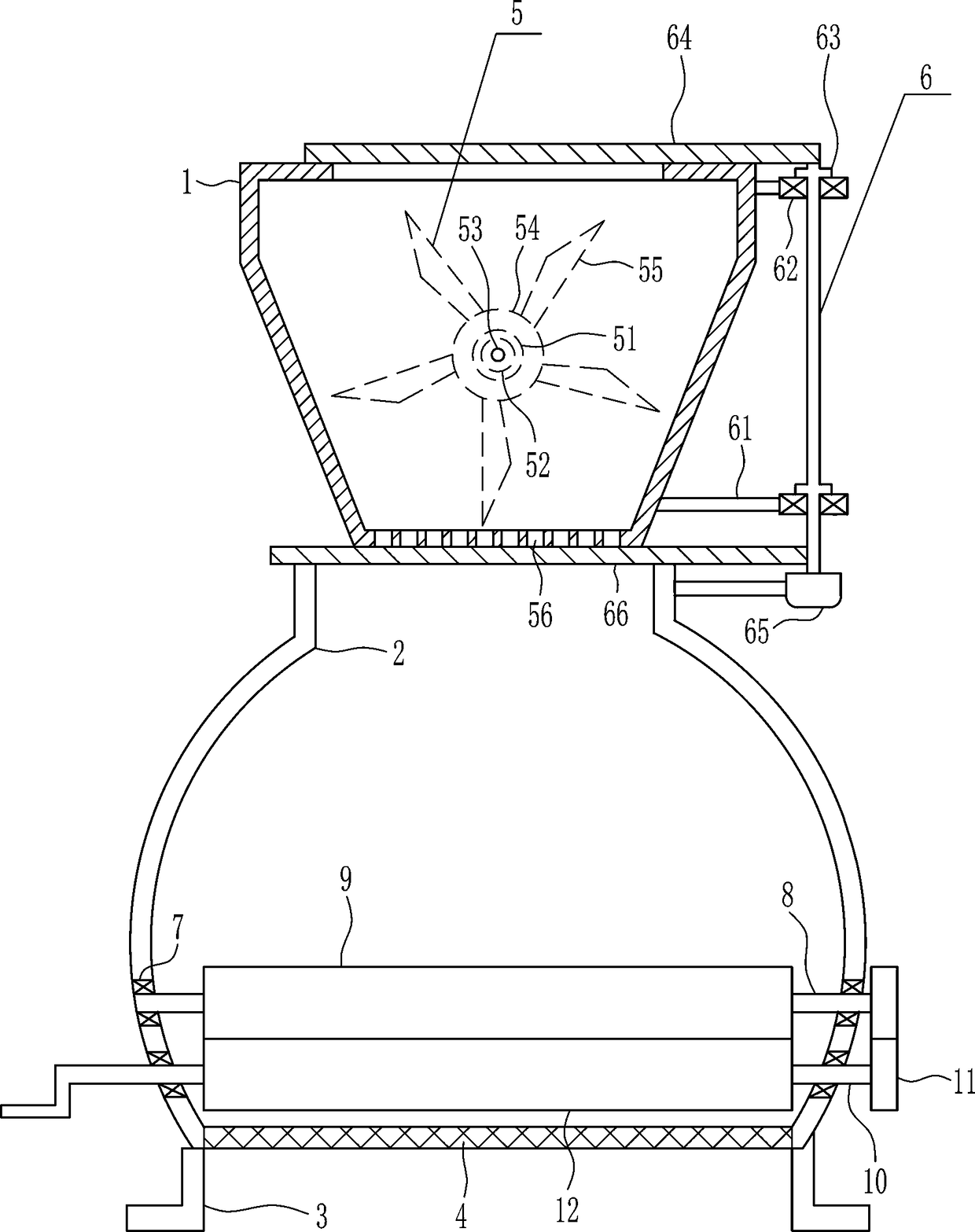

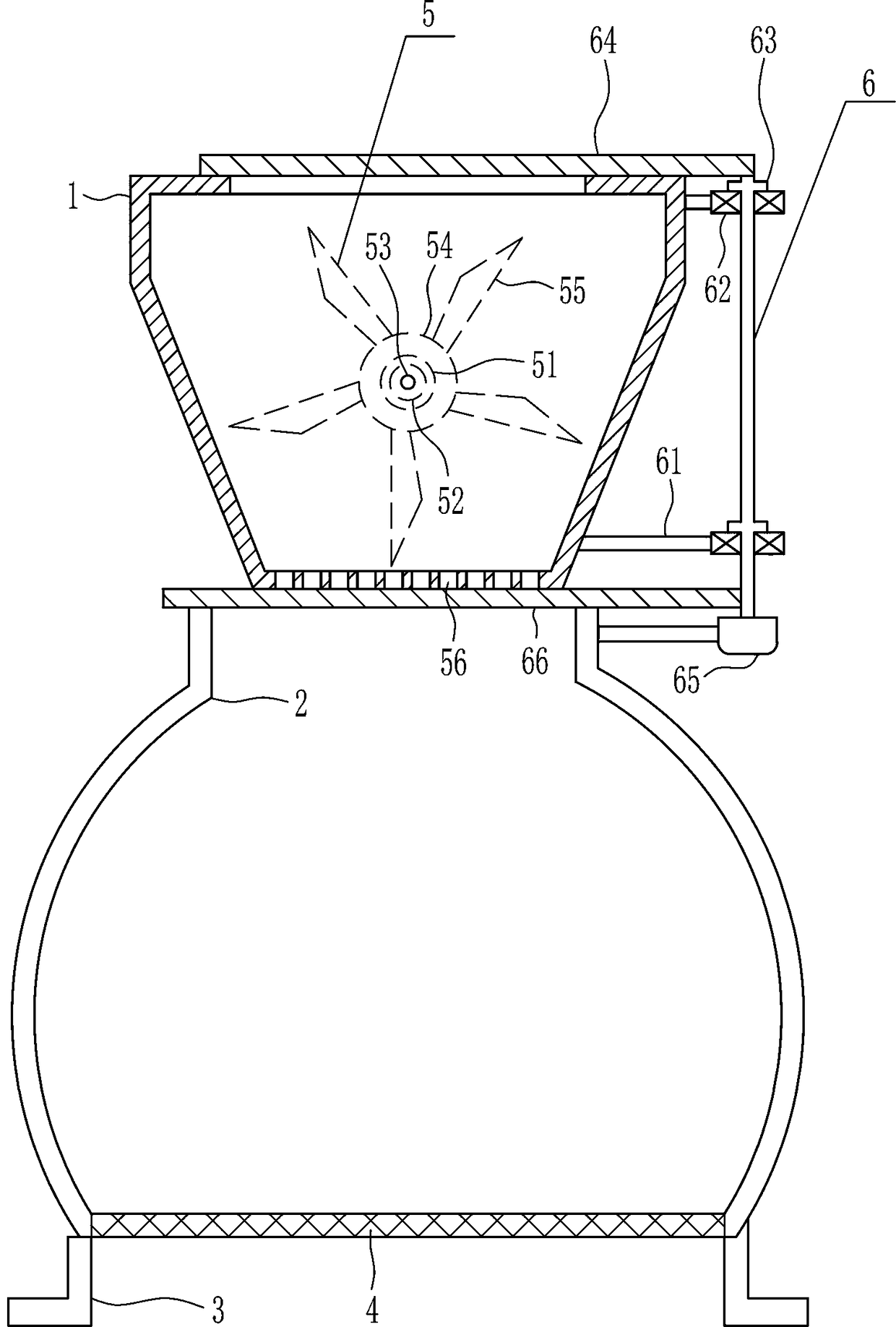

[0032] A machine that can automatically feed and grind rare earth oxides, such as Figure 1-5 As shown, it includes a processing frame 1, a collection frame 2, a support seat 3, a filter screen 4, a crushing mechanism 5, a switch mechanism 6 and a fixed rod 25. 2 The bottom wall is connected with a filter screen 4, the upper left side of the collection frame 2 is connected with a fixed rod 25, the fixed rod 25 is connected with a processing frame 1, the processing frame 1 is located directly above the collection frame 2, and the upper right side of the collection frame 2 is connected with The switch mechanism 6 and the crushing mechanism 5 are arranged in the processing frame 1 .

Embodiment 2

[0034] A machine that can automatically feed and grind rare earth oxides, such as Figure 1-5 As shown, it includes a processing frame 1, a collection frame 2, a support seat 3, a filter screen 4, a crushing mechanism 5, a switch mechanism 6 and a fixed rod 25. 2 The bottom wall is connected with a filter screen 4, the upper left side of the collection frame 2 is connected with a fixed rod 25, the fixed rod 25 is connected with a processing frame 1, the processing frame 1 is located directly above the collection frame 2, and the upper right side of the collection frame 2 is connected with The switch mechanism 6 and the crushing mechanism 5 are arranged in the processing frame 1 .

[0035] The crushing mechanism 5 includes a first motor 51, a first bearing seat 52, a first rotating rod 53, a runner 54 and a crushing rod 55. The bottom wall of the processing frame 1 is evenly opened with small holes 56, and the outer rear wall of the processing frame 1 is connected in the middle...

Embodiment 3

[0037] A machine that can automatically feed and grind rare earth oxides, such as Figure 1-5 As shown, it includes a processing frame 1, a collection frame 2, a support seat 3, a filter screen 4, a crushing mechanism 5, a switch mechanism 6 and a fixed rod 25. 2 The bottom wall is connected with a filter screen 4, the upper left side of the collection frame 2 is connected with a fixed rod 25, the fixed rod 25 is connected with a processing frame 1, the processing frame 1 is located directly above the collection frame 2, and the upper right side of the collection frame 2 is connected with The switch mechanism 6 and the crushing mechanism 5 are arranged in the processing frame 1 .

[0038] The crushing mechanism 5 includes a first motor 51, a first bearing seat 52, a first rotating rod 53, a runner 54 and a crushing rod 55. The bottom wall of the processing frame 1 is evenly opened with small holes 56, and the outer rear wall of the processing frame 1 is connected in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com