Batten pre-connection assembly for wood-processing machine

A technology for processing machines and wooden strips, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc. It can solve the problems of easily damaged wooden strip connection teeth, reduce the yield of finished products, and affect the connection effect, etc., to achieve Strong versatility and practicability, improved production quality, better flattening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

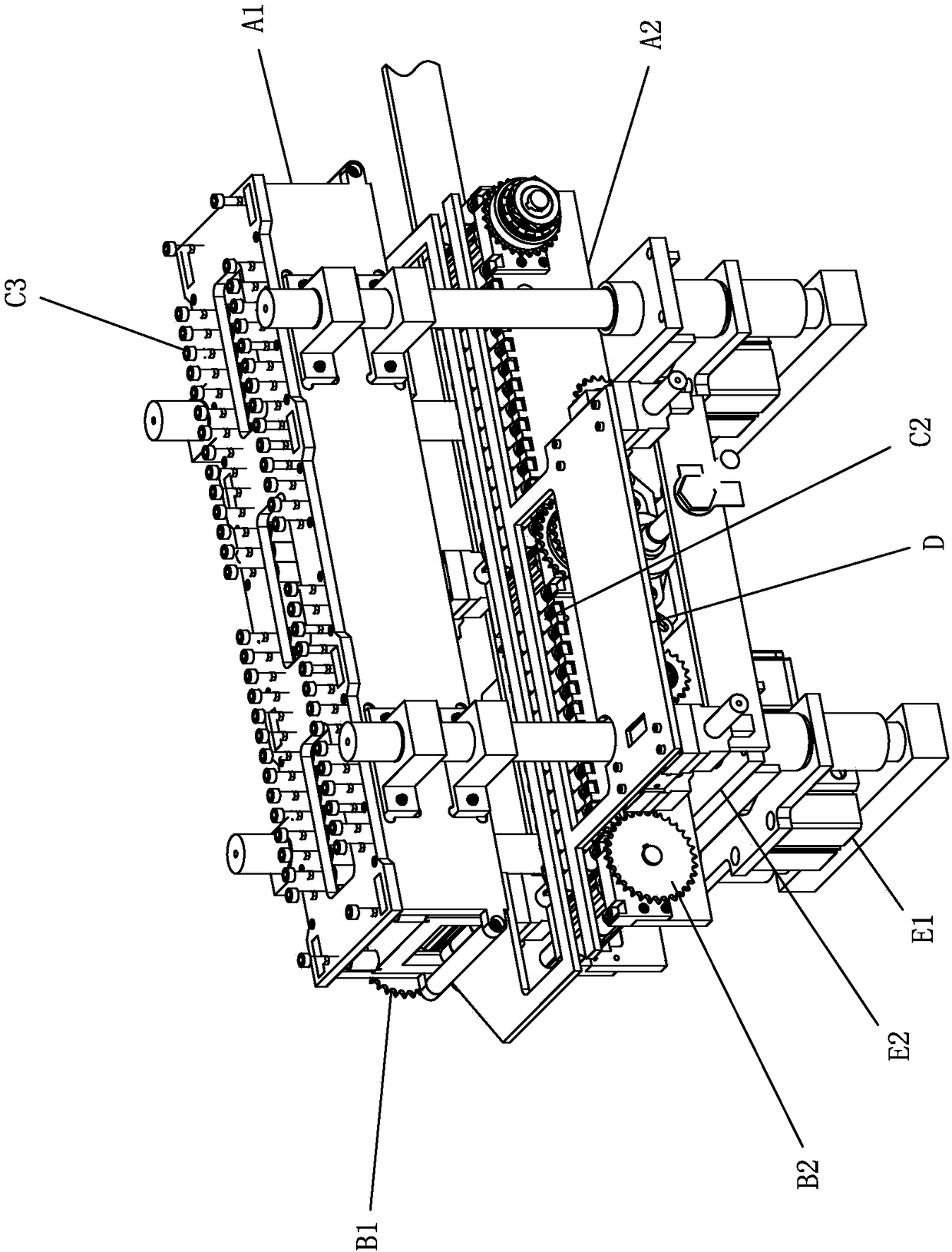

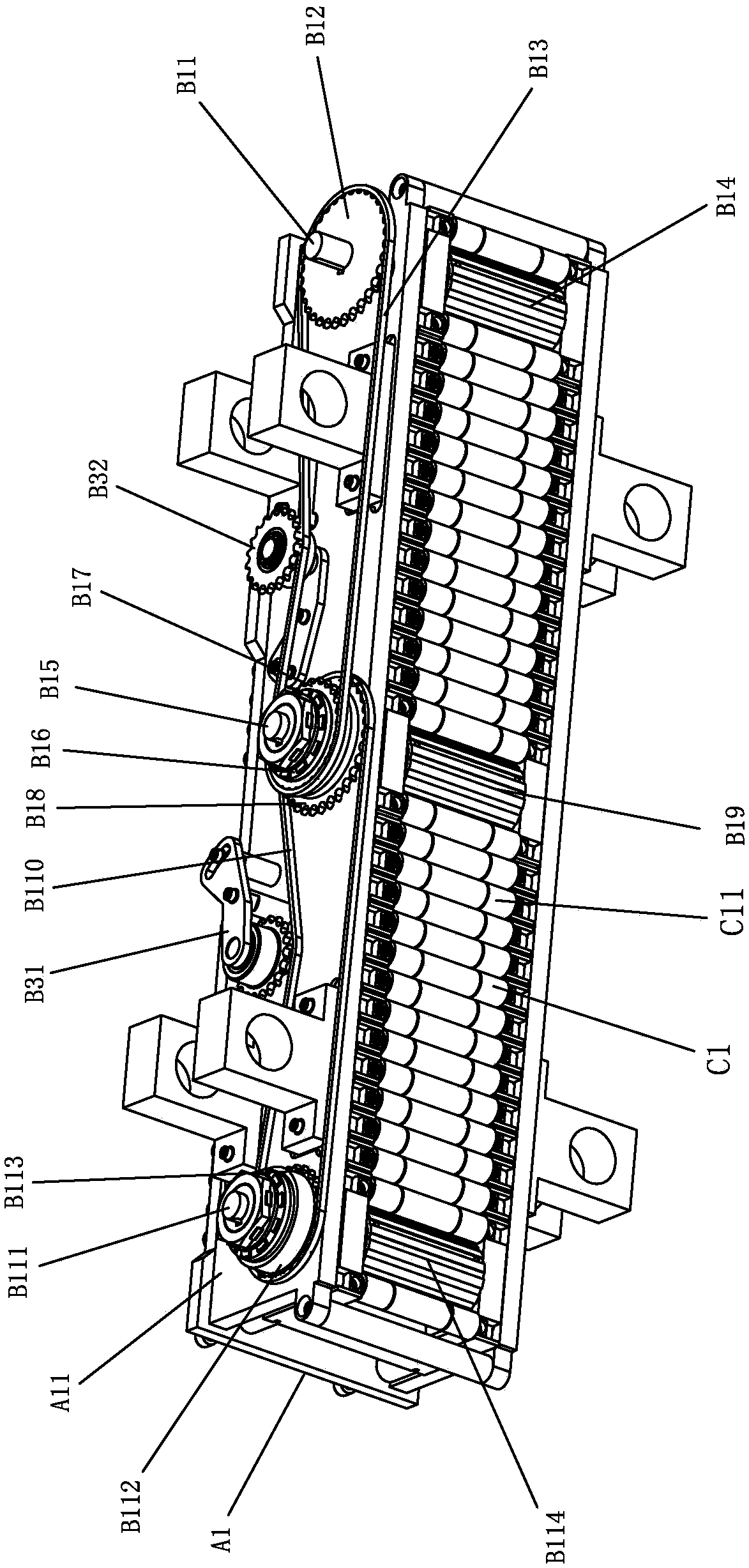

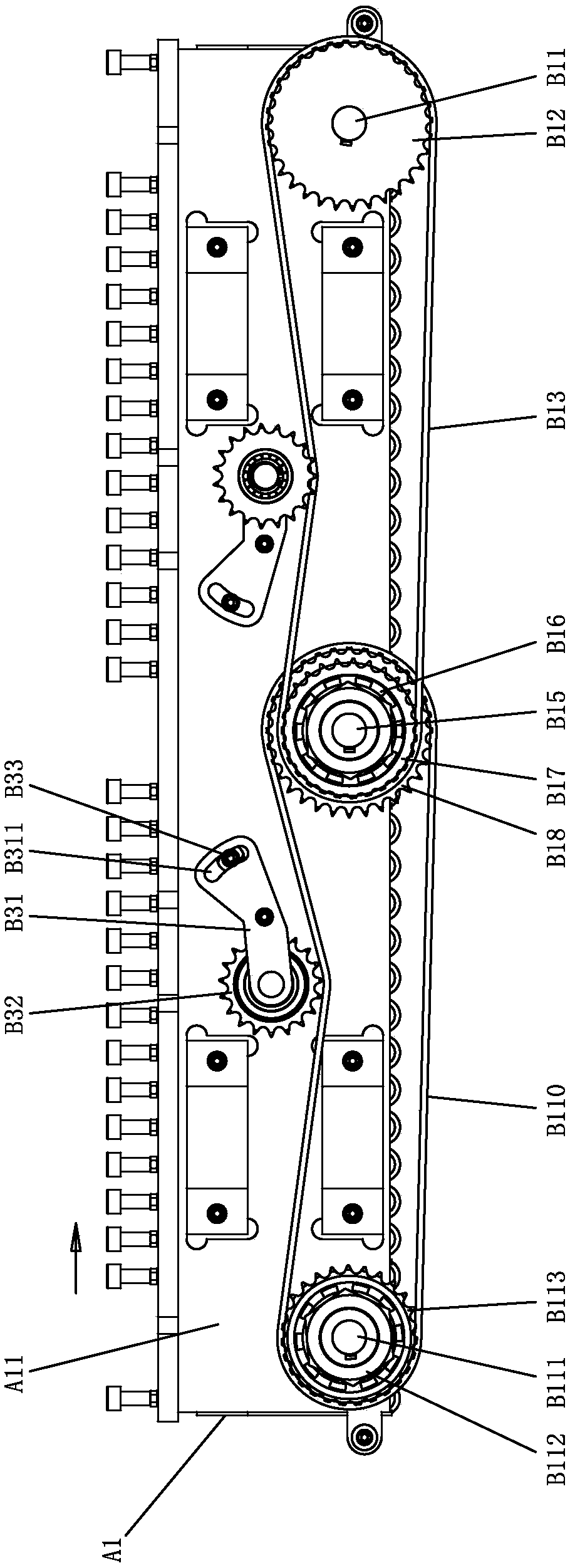

[0038] see Figure 1-Figure 13 , the wooden strip pre-joining assembly for the wood processing machine, including the base composed of the upper frame A1 and the lower frame A2, the upper frame A1 and the lower frame A2 correspond to each other up and down, and they are spaced apart from each other to form a transmission connecting station;

[0039] In addition, it also includes

[0040] The differential connection mechanism includes the upper differential connection assembly B1 arranged on the upper frame A1 and the lower differential connection assembly B2 arranged on the lower frame A2, and is used to drive the upper differential connection assembly B1 The connection drive motor that works simultaneously with the lower differential connection assembly B2; the upper differential connection assembly B1 corresponds to the lower differential connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com