High-activity 99-grade calcium oxide electric burning furnace kiln and calcining method

A calcium oxide, high-activity technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of not being able to obtain double-high products and fail to meet high-end requirements, so as to ensure high purity and good protection , the effect of preventing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

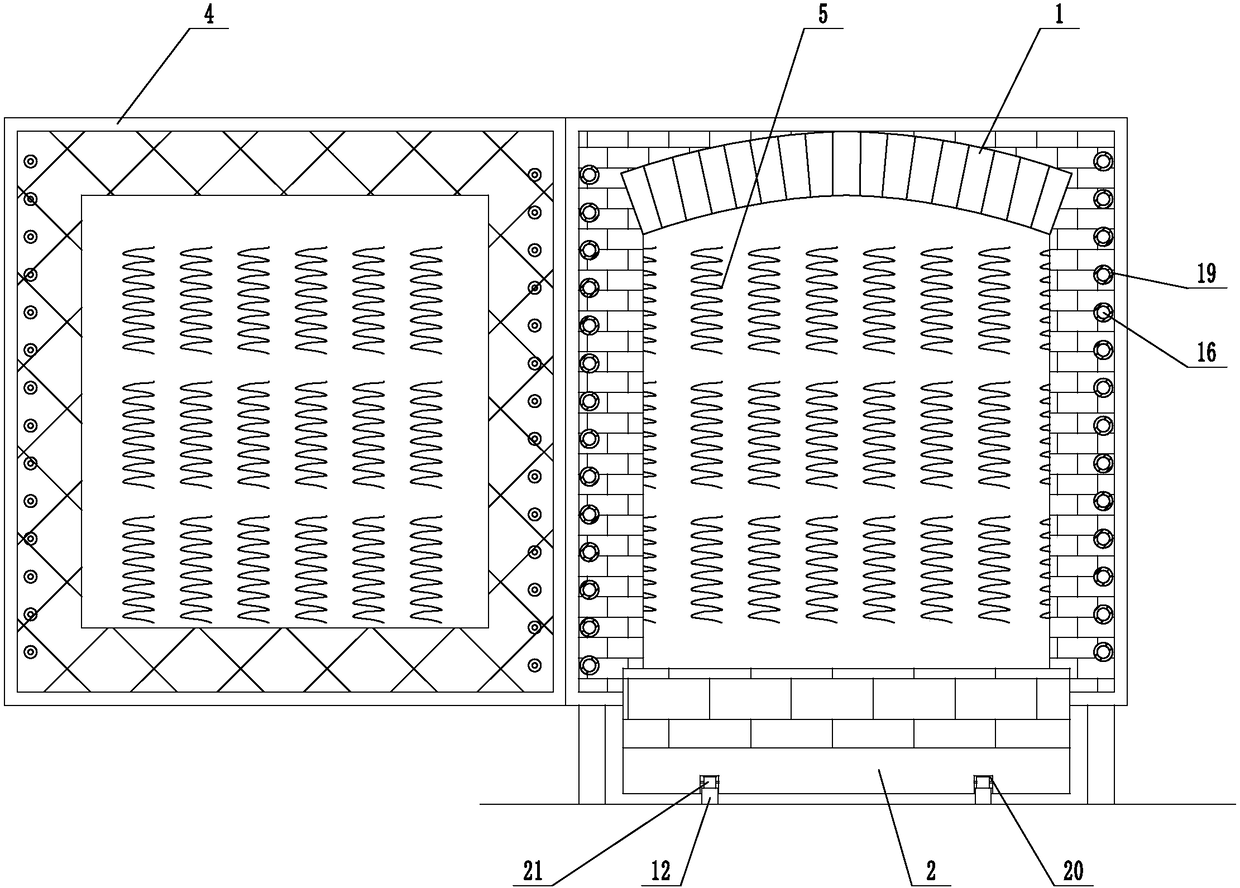

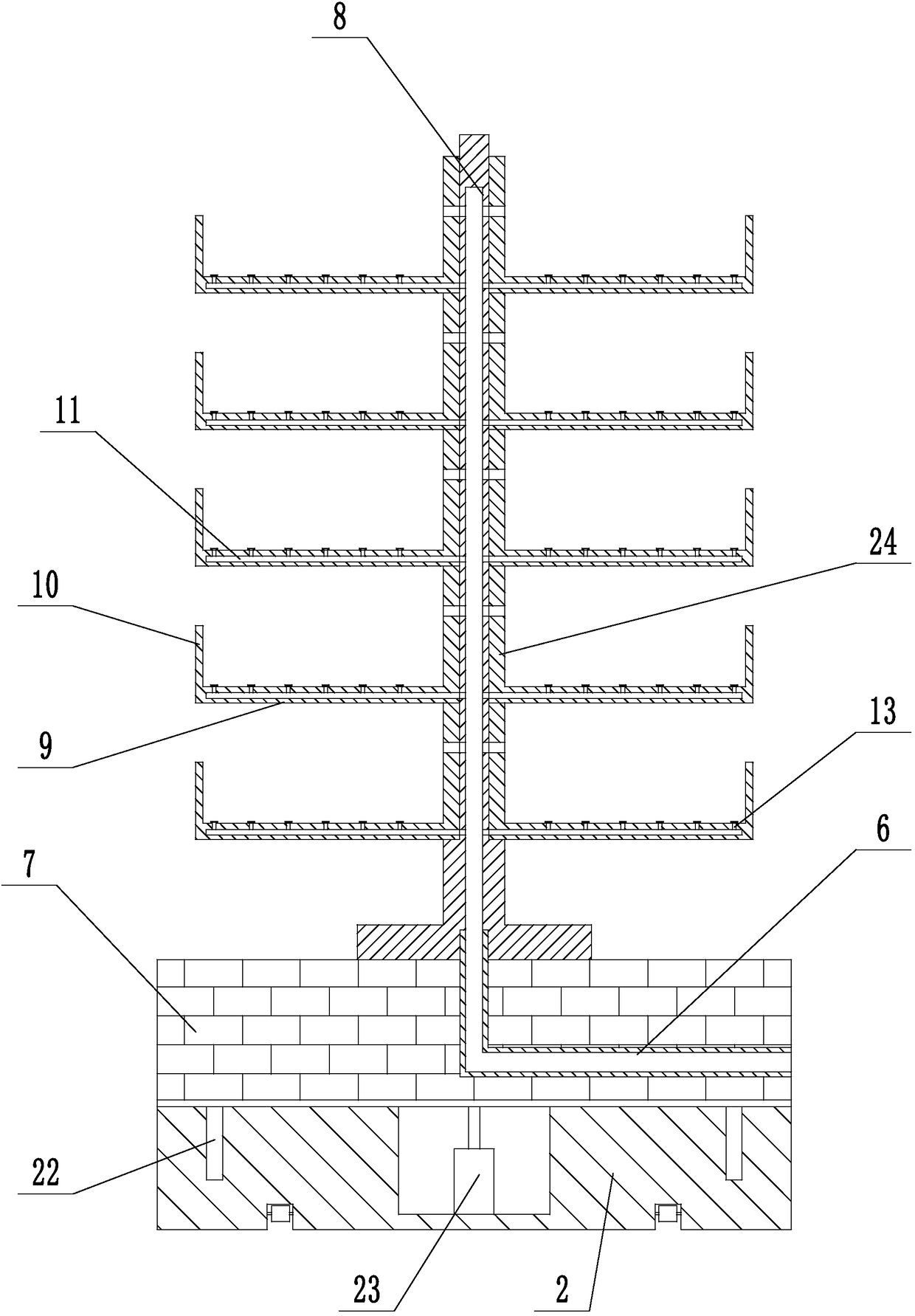

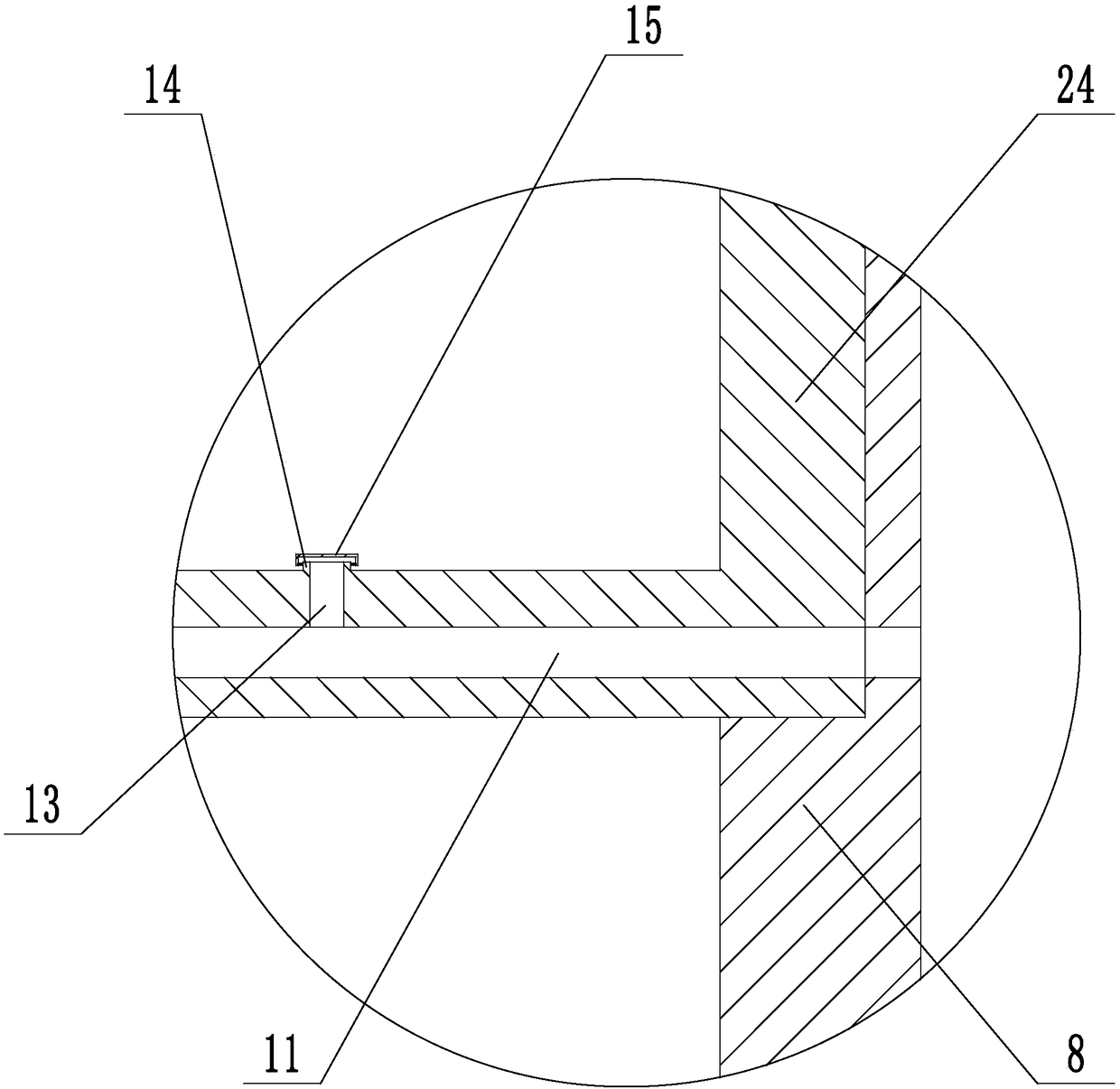

[0033] Embodiment: a kind of highly active 99-grade calcium oxide electric furnace kiln (see attached Figures 1 to 4 ), including the kiln body 1, the kiln car 2 that is movable in the kiln body, the guide rail 12 is arranged under the kiln body, the chute 20 is arranged on the lower surface of the kiln car, and the roller 21 is installed in the chute, the chute on the kiln car and The rails are fitted and the rollers are supported on the rails. The kiln car is stacked with calcite molding blocks 3 formed by compressing broken calcite. There are ventilation gaps between the calcite molding blocks. The kiln body is equipped with a kiln door 4. Electric heating wires are installed on the inner wall of the kiln body and the inner surface of the kiln door. 5. There is an air inlet 6 on the kiln car. One end of the air inlet is connected to the kiln body cavity, and the other end of the air inlet hole is connected to the air intake mechanism. The kiln body cavity is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com