High antimony content lead electrolysis anode mud cleaning equipment and cleaning method thereof

A cleaning equipment and lead electrolysis technology are applied in the cleaning equipment and the cleaning field of high antimony-containing lead electrolysis anode slime, which can solve the problems of high labor intensity, large water consumption, low efficiency, etc. The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

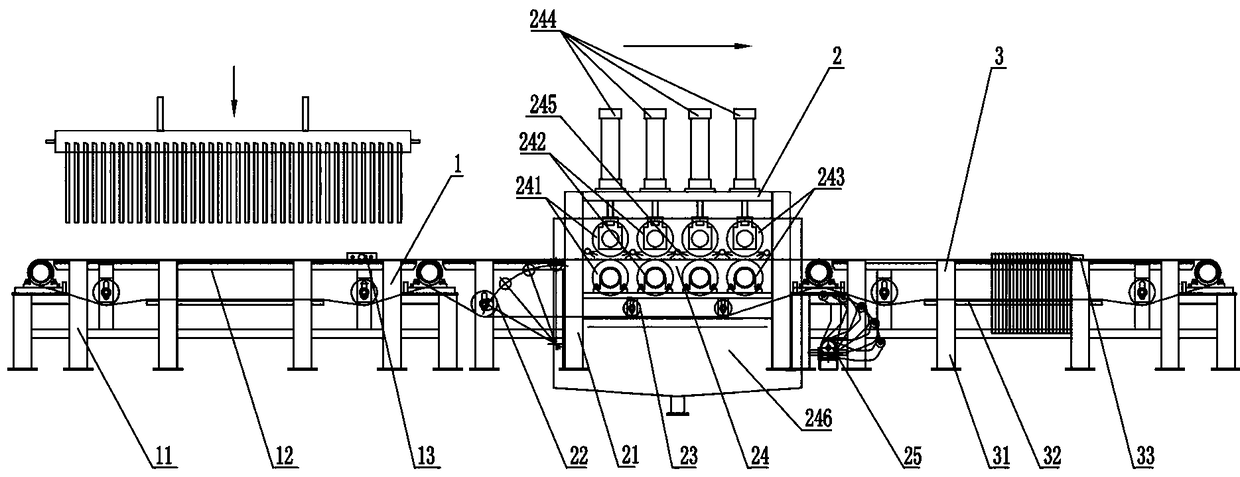

[0035] Such as Figure 1 to Figure 6 As shown, the equipment is mainly composed of three units: the entrance receiver 1, the washing machine 2, and the gathering conveyor 3. The main function of the entrance receiver 1 is to receive the anode plate from the crane to complete the work of centering and conveying. The washing machine 2 Its main function is to flatten the anode plate from a vertical state to a horizontal state, and to crush, scrape and scrub the anode slime remaining on the anode plate, and to turn the anode plate from a horizontal state to a vertical state. The main function of gathering conveyer 3 is to carry out gathering and sorting, convenient driving hangs out.

[0036] The entrance receiver 1 is mainly composed of a receiving frame 11, a receiving and conveying device 12, and a centering device 13. The receiving and conveying device 12 and the centering device 13 are installed on the receiving frame 11 of a steel structure. The receiving and conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com