Connecting joint device and prestress prefabricated member

A technology for connecting joints and prefabricated parts, which is applied in construction, sheet pile walls, and foundation structure engineering, etc. It can solve the problems of decreased pull-out and tensile capacity, difficulty and high cost of button barrel processing, and high firmness and hardness of elastic sheets. Achieve the effect of avoiding the damage of the stress of the steel parts, avoiding the decline of the pull-out and tensile capacity, and improving the reliability of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

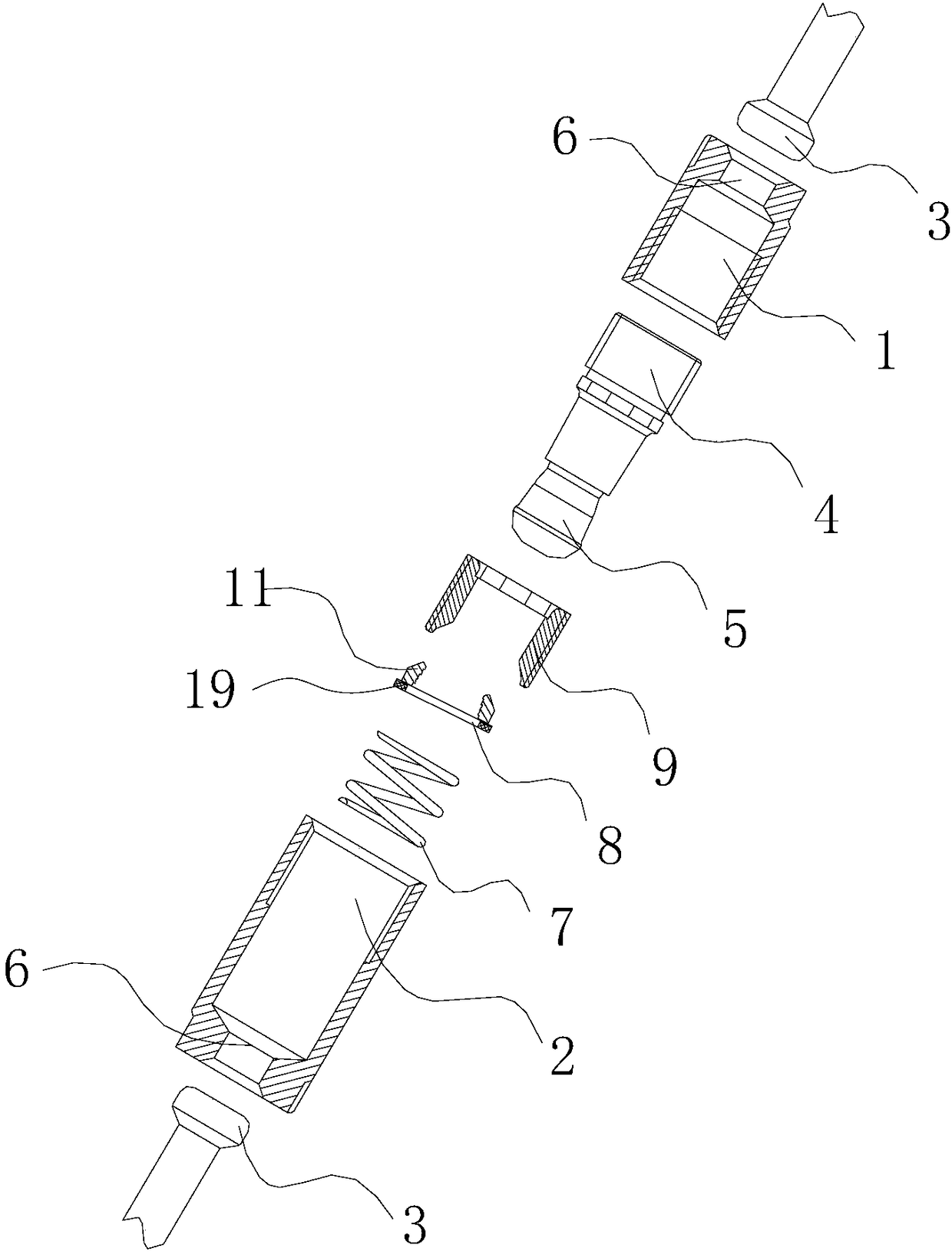

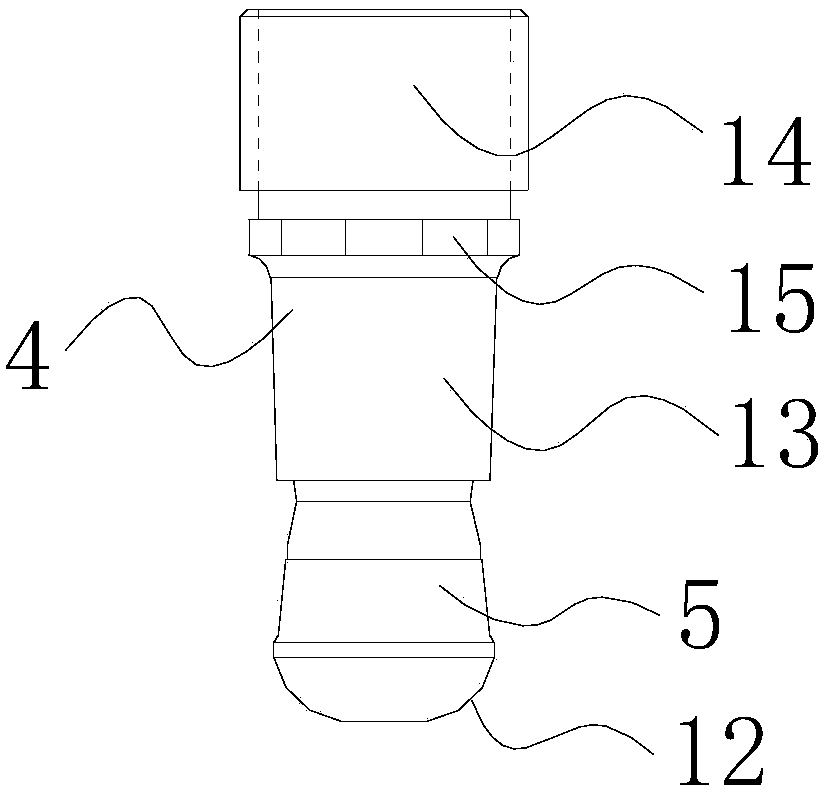

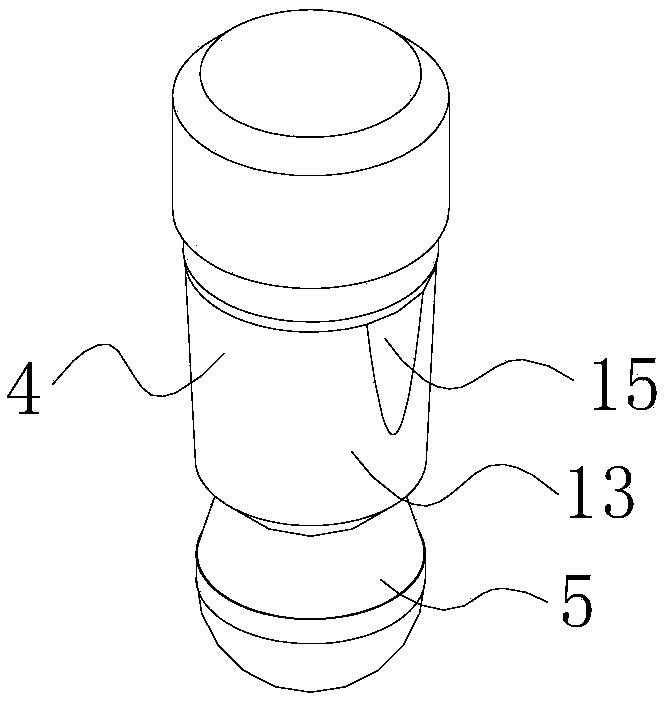

[0034] Such as figure 1 As shown, the present invention provides a connecting joint device, which includes an upper nut 1 and a lower nut 2, and the bottoms of the upper nut 1 and the lower nut 2 are provided with rib holes 6 for clamping with the rigid expansion head 3 , the end of the upper nut 1 away from the rib hole 6 is threadedly connected with an insertion rod 4, the insertion rod 4 is provided with a plug joint 5, and the lower nut 2 is arranged in turn with an elastic element 7, a buckle barrel 8 and a limit nut away from the rib hole 6 9. Wherein, the buckle cylinder 8 includes a card table 11 and a base 19, the card table 11 is slidably connected to the base 19, the card table 11 can slide radially relative to the base 19, that is, the card table 11 can be opened or closed in the lower nut 2 Narrowing, wherein the sliding connection is a sliding connection formed by a groove and a guide rail, and a groove can be set on the card table 11, and a raised guide rail is ...

Embodiment 2

[0042] Such as Figure 8 , 9 , 10, the present embodiment is basically the same as Embodiment 1, the difference is that a card support 18 is provided between the card platform 11 and the base 19, the card platform 11 is fixedly connected with the card platform 18, and the card platform 18 is connected to the base 19 Radial sliding connections.

[0043] Specifically, the buckle cylinder 8 includes a base 19 and a plurality of card tables 11 with a buckle function are evenly spaced along the circumferential direction on the base 19, and the card tables 11 and the base 19 are connected by a card holder 18, so that The base 19, the card support 18, and the card support 11 are split structures, wherein the card support 11 and the card support 18 are fixedly connected, which can be one of bonding, clamping, pin connection or key connection or a combination thereof, The card holder 18 is slidably connected to the base 19. The sliding connection is preferably an inseparable sliding ...

Embodiment 3

[0051] Such as Figure 11 As shown, the present invention also discloses a prestressed prefabricated part, including a first prestressed prefabricated part 20, a second prestressed prefabricated part 21 and a The connecting joint device of the prefabricated part 21, the end faces of the first prestressed prefabricated part 20 and the second prestressed prefabricated part 21 are equal in size, and the interfaces are opposite. The connecting joint device is the connecting joint device of embodiment 1 or embodiment 2, wherein , several longitudinal ribs 22 and transverse ribs in the prestressed prefabricated part constitute the rigid skeleton of the prefabricated part. Both ends of the rib 22 are respectively made as rigid expansion heads 3, and are respectively connected to the upper nut 1 and the lower nut 2 through the rib hole 6, the upper nut 1 is connected to the insertion rod 4, and the lower nut 2 is installed with an elastic element 7 and a button barrel 8 and the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com