Joint implementation tubular column for fracturing and water control production and method

A pipe string and fracturing sliding sleeve technology is applied in the field of joint implementation of fracturing and water control production, which can solve the problems of low oil production in oil wells and inability to control water production in oil wells, and achieves improved oil recovery, Easy to promote and use, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

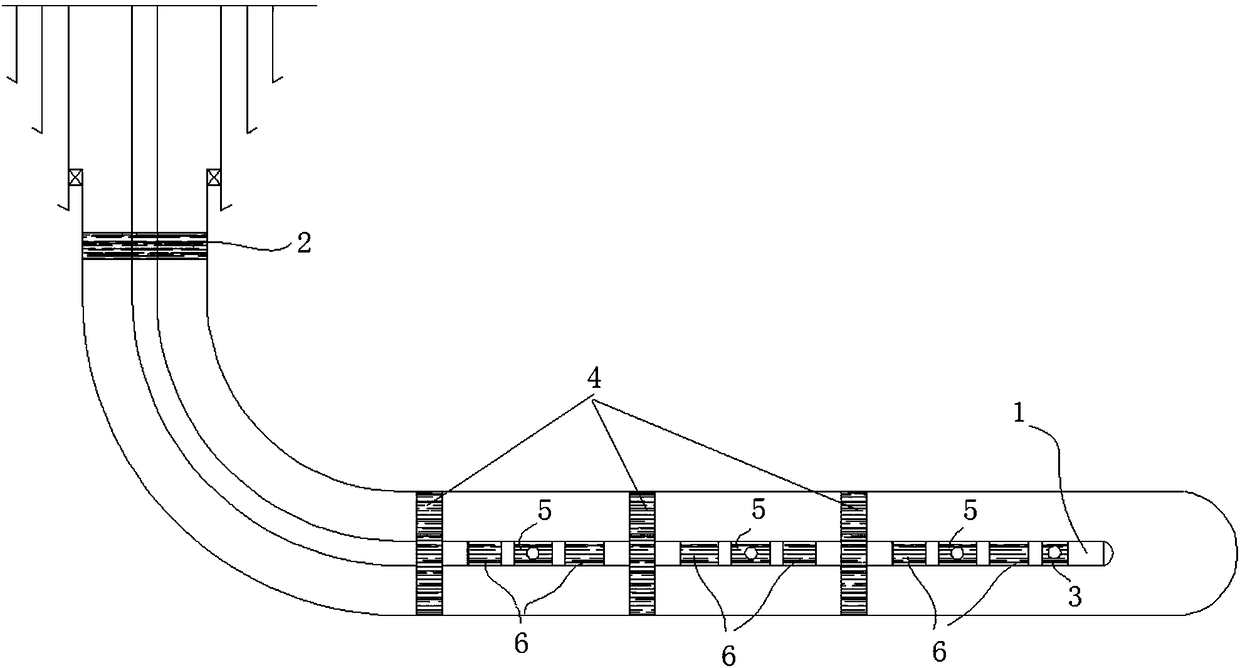

[0033] The present invention also provides a joint implementation method of fracturing and water control production, which includes the following steps:

[0034] Step 1. Run the above-mentioned joint implementation string connected to it into the oil well through the drill pipe, and set the suspension packer 2 and each open hole packer 4 after performing the slurry replacement operation, and then use the back-insertion string to replace Drill pipe;

[0035] Step 2. Inject fracturing fluid into the back-insertion string and put pressure-suppressing balls into it to perform staged fracturing operations. Open the self-closing fracturing sliding sleeve in sequence from close to ball seat 3 to away from ball seat 3 5, and ensure that after the previous self-closing fracturing sleeve 5 is closed, the latter self-closing fracturing sleeve 5 is opened again;

[0036] Step 3, forcing the pressure-suffocating ball to flow back to the ground along with the fracturing fluid, and then rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com