Peristaltic type pipeline robot

A pipeline robot and robot technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of heavy weight, inconvenient maintenance, complex structure, etc., and achieve the effect of increasing the anti-slip effect and ensuring the locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

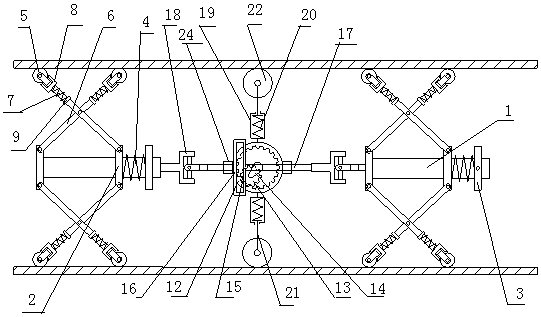

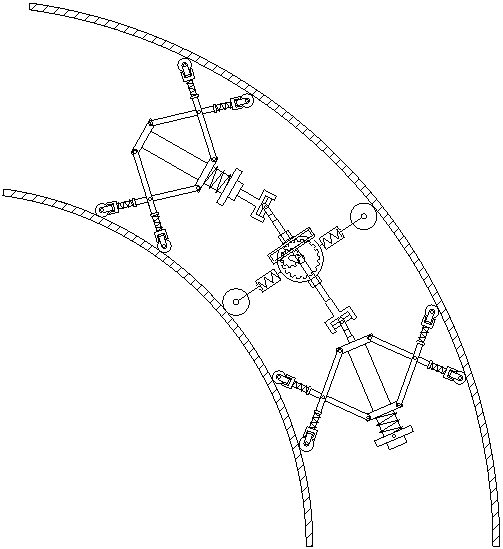

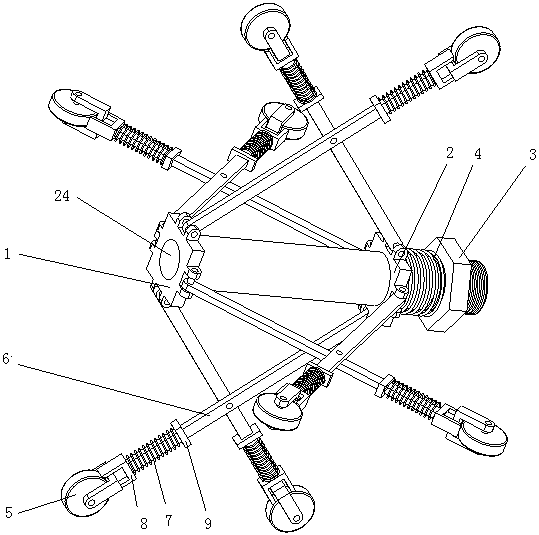

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

[0017]As shown in the accompanying drawings, a peristaltic pipeline robot is composed of a left support mechanism, a right support mechanism and a middle drive mechanism, and it is characterized in that the left support mechanism and the right support mechanism are composed of a sliding shaft 1, four sets of intersecting The hinge rod, the sliding sleeve 2, the lock nut 3, the pre-tension spring 4 and the roller 5 are composed of two rods 6, the inner end of which is connected to the sliding shaft The left end of 1 is hinged, the inner end of another pole 6 is hinged with the sliding sleeve 2 sleeved on the sliding shaft 1, and the outer ends of the two poles 6 are respectively hinged with the roller 5. The sliding shaft 1 The right end is provided with a lock nut 3, and the sliding shaft 1 between the lock nut 3 and the sliding sleeve 2 is sleeved with a pre-tension spring 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com