Sound emission test device of rock body in high-enclosure-pressure unloading and operation method thereof

A testing device and acoustic emission technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of damage to acoustic emission sensors, inability to effectively deploy cyclic impact loads, and difficulty in repeated installation and disassembly of acoustic emission sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

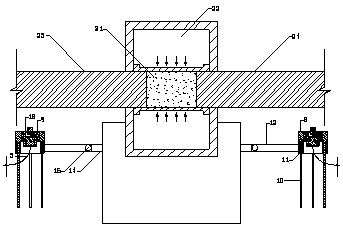

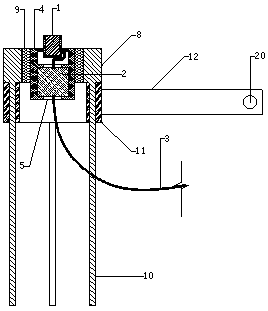

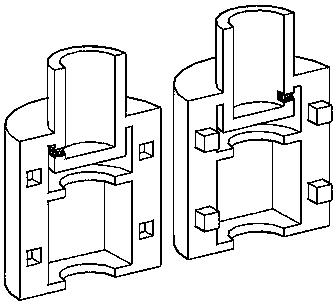

[0046] see Figure 1-7b , an acoustic emission testing device for rock mass in high confining pressure unloading, an acoustic emission testing device for rock mass in high confining pressure unloading, comprising an acoustic emission sensor (1), a preamplifier (2), a coaxial Cable (3), protective shell (4), ring B (8), rubber ring (9), tenon (10), ring A (11), connecting rod (12), mortise (13), short rod (14), bolts (15), nuts (16), buckles (17) and sensor protection devices (18), are characterized in that: the protective shell (4) is divided into two halves that can be assembled, and the acoustic emission sensor ( 1) It is fixedly installed in the groove (7) of the protective shell and the acoustic emission sensor (1) exposes the detection surface;

[0047] The coaxial cable (3) connects the acoustic sensor (1) and the preamplifier (2) and leads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com