Direct-current fuse assembly device

A technology of fuses and main fuses, which is applied in the direction of emergency protection devices, electrical components, circuits, etc., can solve the problems of unsatisfactory operating efficiency and operating safety factor of switching operations, low operating safety factor, and cumbersome operating steps, etc., to achieve Realize the effect of easy operation, assembly and disassembly, large electrical isolation distance, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

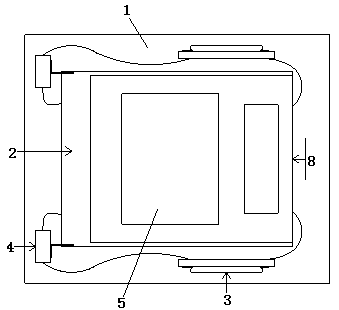

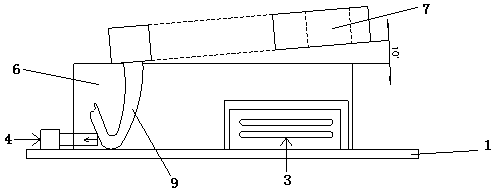

[0026] Such as figure 1 , figure 2 As shown, a DC fuse assembly device includes a base plate 1, a knife fuse switch 2, an alarm mount 3 and a travel switch 4; wherein, the knife fuse switch 2, the alarm mount 3, and the travel switch 4 are all Installed on the bottom plate 1; the alarm mounting base 3 is on both sides of the knife fuse switch 2; the travel switch 4 is connected to the knife fuse switch 2.

[0027] In the specific implementation process, the base plate 1 is used for fixedly installing the knife fuse switch 2, the alarm mounting seat 3 and the travel switch 4, and the whole device is installed at the wiring site; the knife fuse switch 2 is installed in the middle of the base plate 1, and the alarm is installed Seat 3 is installed on knife melting switch 2 both sides.

[0028] More specifically, the knife fuse switch 2 includes a plastic base 6, a box cover 7, an operating handle 8 and a crank arm 9; the plastic base 6 is installed on the bottom plate 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com