Photovoltaic vacuum window for realizing full-solar spectrum management

A solar spectrum and vacuum window technology, applied in the field of photovoltaic vacuum windows, can solve the problems of poor heat dissipation, poor living experience and high cost, and achieve the effect of ensuring performance and service life, improving comprehensive efficiency and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention has no special limitation on the preparation method of the photovoltaic vacuum window that realizes full solar spectrum management, and the technical solution well known to those skilled in the art can be adopted. In the present invention, the preparation of the photovoltaic vacuum window that realizes full solar spectrum management preferably includes the following steps:

[0038] vacuumizing the first glass and the second glass after sealing treatment to obtain a vacuum glass layer;

[0039] Prepare a nano photocatalytic film on one surface of the third glass to obtain a self-cleaning functional layer;

[0040] Depositing a second transparent electrode, a photovoltaic thin film and a first transparent electrode in sequence on the other surface of the third glass to obtain a self-cleaning photovoltaic glass;

[0041] The vacuum glass layer is combined with the self-cleaning photovoltaic glass, and the second glass is connected with the first tran...

Embodiment 1

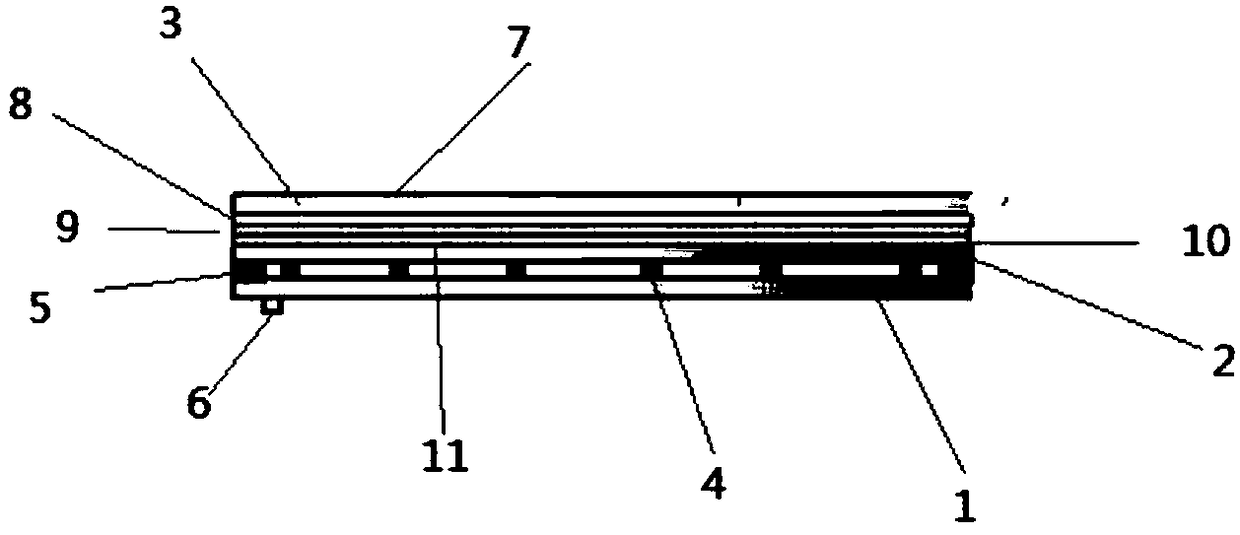

[0051] The schematic diagram of the structure of the photovoltaic vacuum window that realizes full solar spectrum management prepared in this example is as follows figure 1 As shown, it includes a vacuum glass layer, a photovoltaic power generation layer and a self-cleaning functional layer arranged in sequence from the inside to the outside. The vacuum glass layer includes a first glass 1 , a second glass 2 and a vacuum layer formed between the first glass 1 and the second glass 2 . The photovoltaic power generation layer includes a first transparent electrode 8, a photovoltaic thin film 9 and a second transparent electrode 10 arranged in sequence; the photovoltaic thin film is a light-transmitting photovoltaic thin film; Three glasses 3 and nano photocatalytic film 7; the first transparent electrode 8 and the second transparent electrode 10 are TCO layers; the vacuum glass layer and the photovoltaic power generation layer are connected by an interlayer 11, and the interlayer...

Embodiment 2

[0059] The schematic diagram of the structure of the photovoltaic vacuum window that realizes full solar spectrum management prepared in this example is as follows figure 1 As shown, it includes a vacuum glass layer, a photovoltaic power generation layer and a self-cleaning functional layer arranged in sequence from the inside to the outside. The vacuum glass layer includes a first glass 1 , a second glass 2 and a vacuum layer formed between the first glass 1 and the second glass 2 . The photovoltaic power generation layer includes a first transparent electrode 8, a photovoltaic thin film 9 and a second transparent electrode 10 arranged in sequence; the photovoltaic thin film is a light-transmitting photovoltaic thin film; Three glasses 3 and nano photocatalytic film 7; the first transparent electrode 8 and the second transparent electrode 10 are TCO layers; the vacuum glass layer and the photovoltaic power generation layer are connected by an interlayer 11, and the interlayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com