Combined rod-shaped material container

A combined, material technology, applied in the fields of food science, application, tobacco, etc., can solve the problem that it is impossible to economically form a container for receiving and storing rod-shaped materials of various lengths, and it is impossible to receive and store rod-shaped materials of various length specifications. , production, storage, management costs increase and other issues, to achieve the effect of novel design concept, flexible assembly, and reduce management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

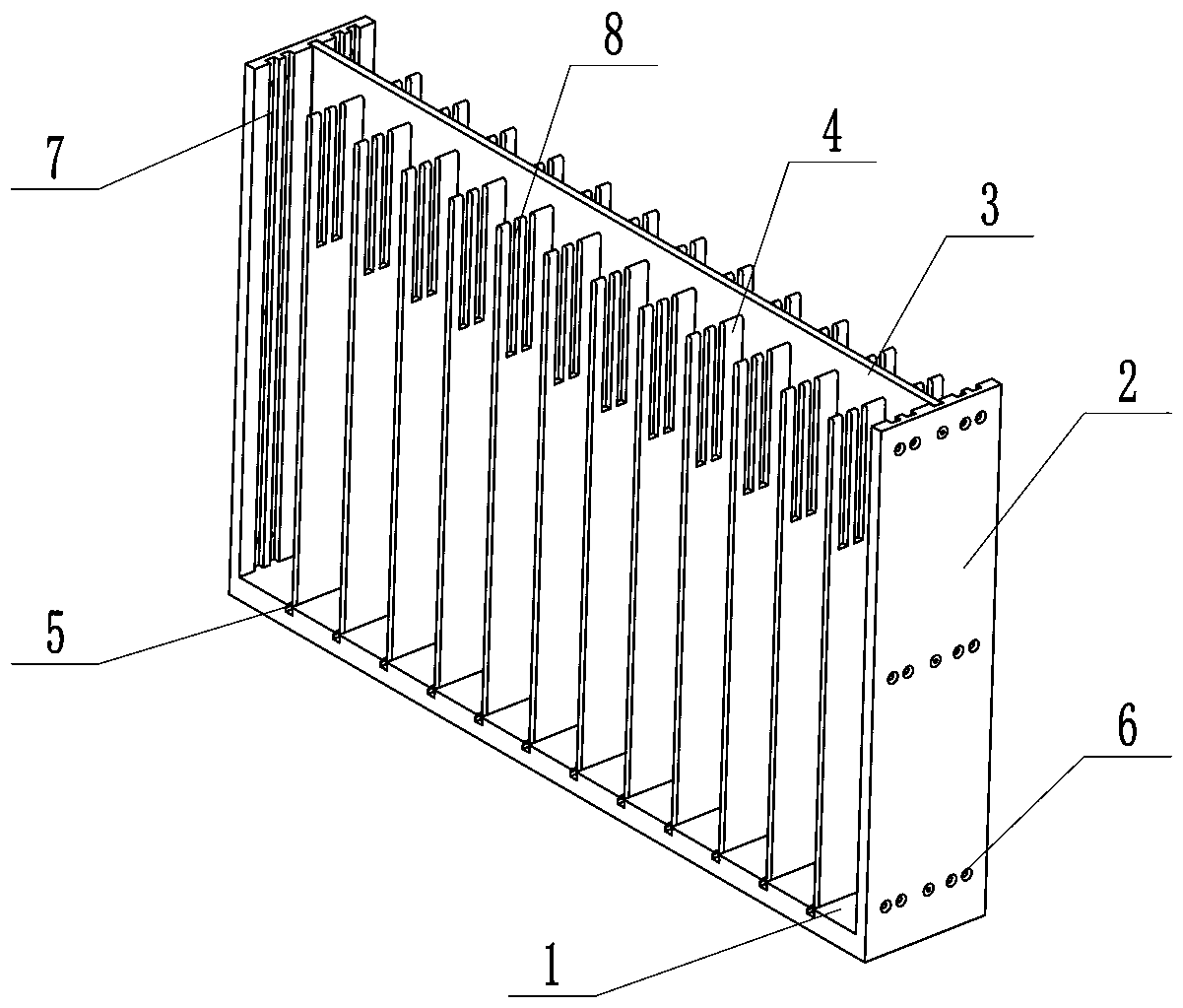

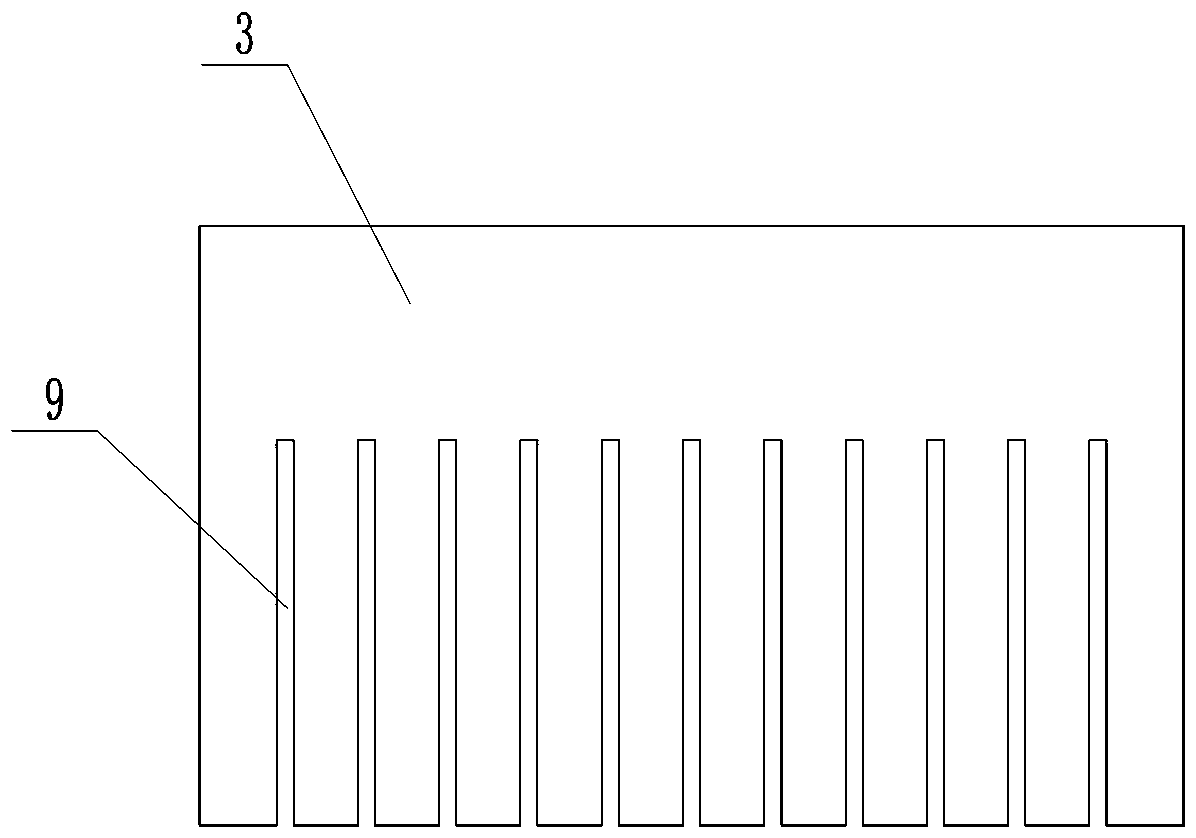

[0022] The technical solution of the combined adjustable rod-shaped material container according to the present invention will be further described in detail through specific implementation methods below.

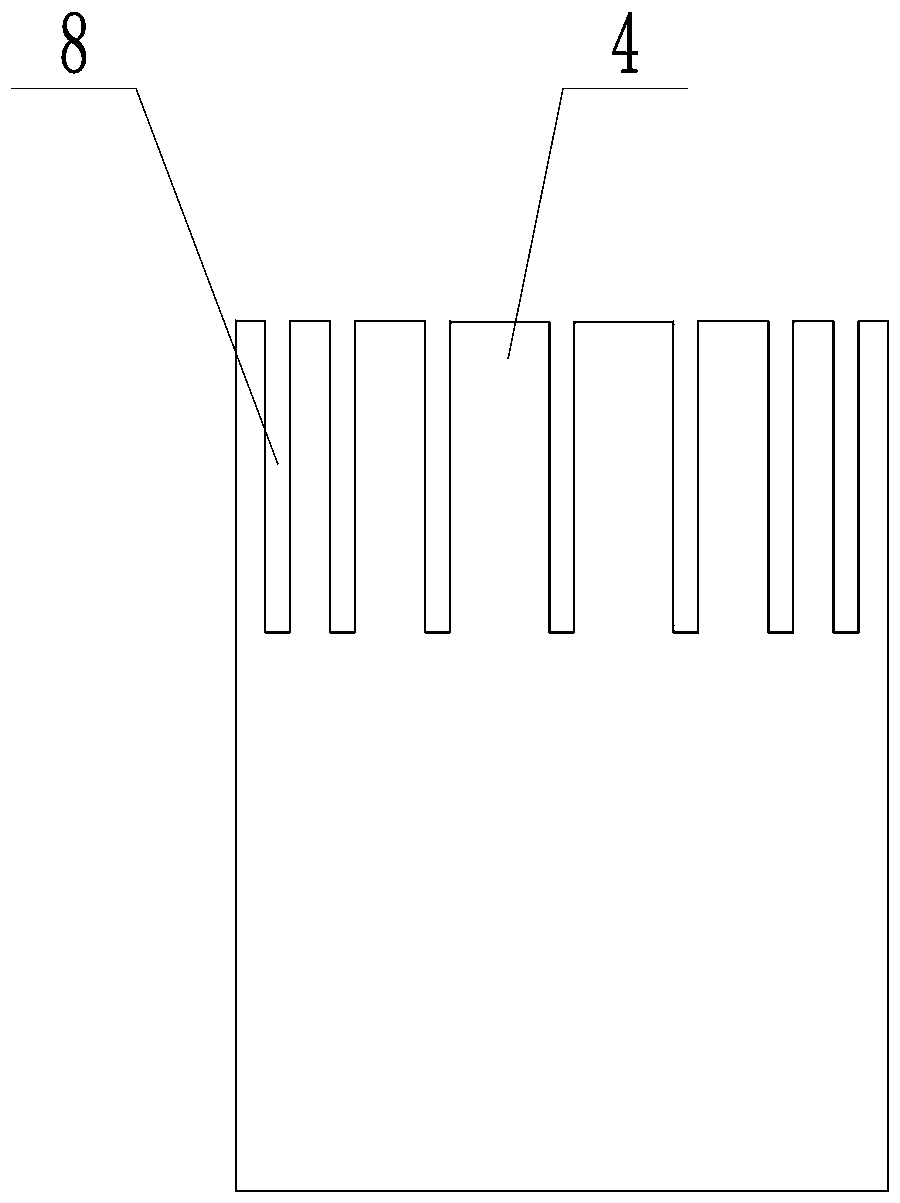

[0023] like figure 1 , figure 2 , image 3 As shown, a combined rod-shaped material container, the container includes a tray body and a rear wall 3, a partition wall 4, the tray body is composed of a bottom wall 1 and two parallel and separated side walls 2, the tray body A container is enclosed with the rear wall, and the partition wall is inserted into the bottom groove 5 of the bottom wall and is located between the two side walls to divide the container into multiple storage units.

[0024] There are one or more sets of guide grooves 7 on the side wall 2, and the guide grooves 7 are vertically arranged along the inner side of the side wall. According to the different lengths of the rod-shaped materials to be accommodated and stored, one set of guide grooves can be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com