Residual oil hydrogenation reactor with alternately changed material flow directions, residual oil hydrogenation system containing reactor and residual oil hydrogenation process

A technology for residual oil hydrogenation and reaction system, which is applied in the petroleum industry, processing hydrocarbon oil, refining to remove heteroatoms, etc. Small area and other issues, to achieve the effect of improving space utilization, extending the service life, and reducing varieties and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

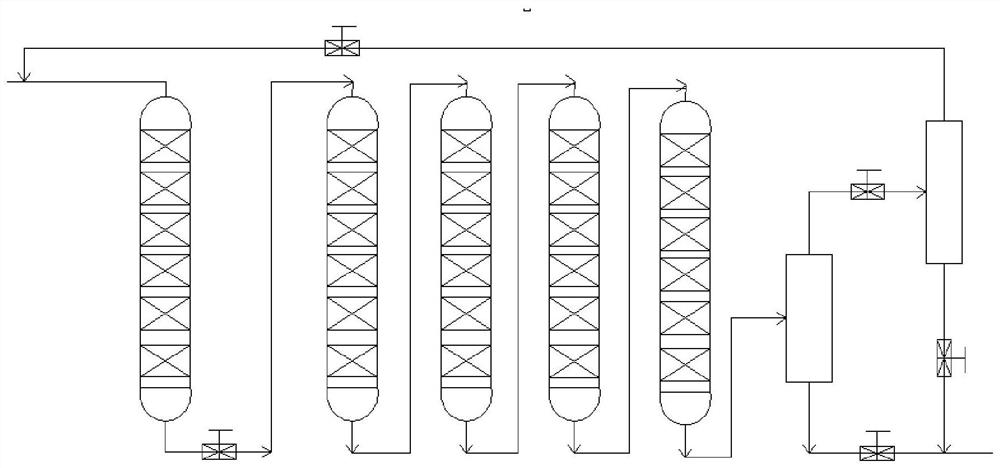

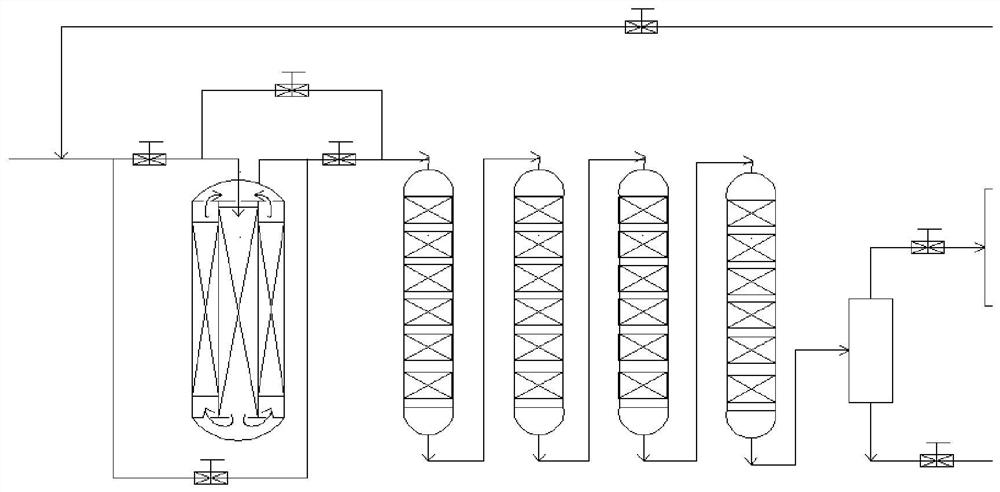

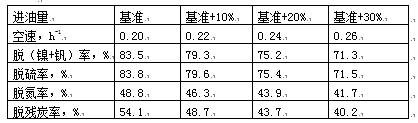

[0044] Adopt the raw material identical with following comparative example 1, catalyst kind and filling method thereof, carry out such as figure 2 The shown material flow direction of the present invention alternately changes residue hydrogenation fixed-bed reactor, system and technology thereof and such as figure 1 The process operation comparison of the conventional residual oil hydrogenation fixed-bed reactor, system and its process is shown.

[0045] Wherein, the reactor of the present invention that material flow changes alternately is used as protective agent and / or demetallization reactor, i.e. the first reactor, such as figure 2 As shown, the catalyst bed in the reactor is physically divided into two sandwich structures with equal cross-sectional areas by a cylinder with the same central axis as the reactor cylinder, and its height is the original conventional reactor ( figure 11 / 2 of the height of the first reactor in the cylinder), the flow direction of the residu...

Embodiment 2

[0058] Using the same raw materials, functional catalysts, catalyst gradation loading ratios and reaction conditions as in the following comparative example 2, carry out as follows figure 2 The shown residue hydrogenation fixed-bed reactor of the present invention, system and technology thereof and such as figure 1 The process operation comparison of the conventional residual oil hydrogenation fixed-bed reactor, system and its process is shown.

[0059] Wherein, the reactor in which the material flow direction of the present invention is alternately changed is used as a protective agent and / or a demetallization reactor, that is, the first reactor, and the catalyst bed in the reactor is covered by one having the same central axis as the reactor cylinder The cylinder is physically divided into two sandwich structures with equal cross-sectional areas, and its height is the original conventional reactor ( figure 1 1 / 3 of the height of the first reactor in the cylinder), the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com