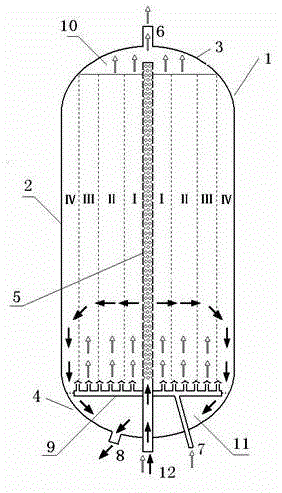

Residual oil hydrotreating method

A technology for hydrogenation and treatment of residual oil, applied in refining to remove heteroatoms, etc., can solve problems such as waste of active resources of post-catalysts, and achieve the effects of good operating flexibility, reduced flow resistance, and small pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The same catalyst type and its loading method were used to compare the operating elasticity of the radial-flow fixed bed of the present invention and the existing fixed bed residue hydrogenation technology.

[0039] In this example, the residue hydrogenation catalyst developed and produced by Fushun Petrochemical Research Institute (FIRPP) was used. The protective agent was FZC-13, the hydrodemetallization catalyst was FZC-21, and the hydrodesulfurization catalyst was FZC-30. , the hydrodenitrogenation catalyst is FZC-41, and in the catalyst bed, the loading ratio of various functional catalysts is FZC-13:FZC-21:FZC-30:FZC-41=13:32:20:35. The raw material oil is a Middle Eastern atmospheric residue, and its impurity content is as follows: S=2.78m%, N=0.29m%, CCR=12.1m%, Ni+V=110μg / g. The reaction conditions are: reaction pressure 15.7MPa, reaction temperature 370°C, hydrogen-to-oil volume ratio 700, and the oil feed rate is 0.2h at the existing fixed bed space velocity ...

Embodiment 2

[0048] Using the same catalyst species and loading method as in Example 1, the stability comparison between the radial-flow fixed bed technology of the present invention and the existing fixed bed residual oil hydrogenation technology was carried out.

[0049] In this example, a batch of residual oil hydrogenation catalysts prepared by FIRPP laboratory is used. The protective agent is FZC-14, the hydrodemetallization catalyst is FZC-28, the hydrodesulfurization catalyst is FZC-34, and the hydrodenitrogenation catalyst is FZC-34. The catalyst is FZC-42, and the gradation of each catalyst in the reactor is FZC-14:FZC-28:FZC-34:FZC-42=13:32:23:32. The raw material oil is another Middle Eastern atmospheric residue, and its impurity content is as follows: S=2.67m%, N=0.31m%, CCR=13.57m%, Ni+V=126μg / g. The reaction conditions are: reaction pressure 15.7MPa, reaction temperature 375°C, hydrogen-to-oil volume ratio 700, and the oil feed rate is 0.2h at the space velocity of the existi...

Embodiment 3

[0058] Using the same catalyst type and its loading method, the relationship between the running time and temperature of the radial-flow fixed bed of the present invention and the existing fixed bed residual oil hydrogenation technology is carried out.

[0059] Adopt the same raw material and catalyzer among the embodiment 1 among the embodiment 3. The reaction pressure is 15.7MPa, the volume ratio of hydrogen to oil is 700, and the space velocity is 0.2h -1 , The reaction temperature is 365°C.

[0060] Table 5 Results of residual oil hydrogenation method of the present invention

[0061] running time, h 1000 2000 4000 Reaction temperature, °C 365 365 365 Desulfurization rate, % 80.20 80.23 80.31 Nitrogen removal rate, % 46.23 46.27 46.38 Carbon residue removal rate, % 53.62 53.66 53.71 Stripping (nickel + vanadium) rate, % 81.35 81.40 81.51 Differential pressure, kPa 0 0 0

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com