Layering type solid-liquid extracting device

An extraction device and a layered technology, applied in the field of layered solid-liquid extraction devices, can solve problems such as lowering the solution temperature, achieve the effects of enhancing disturbance, increasing the update rate, and improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

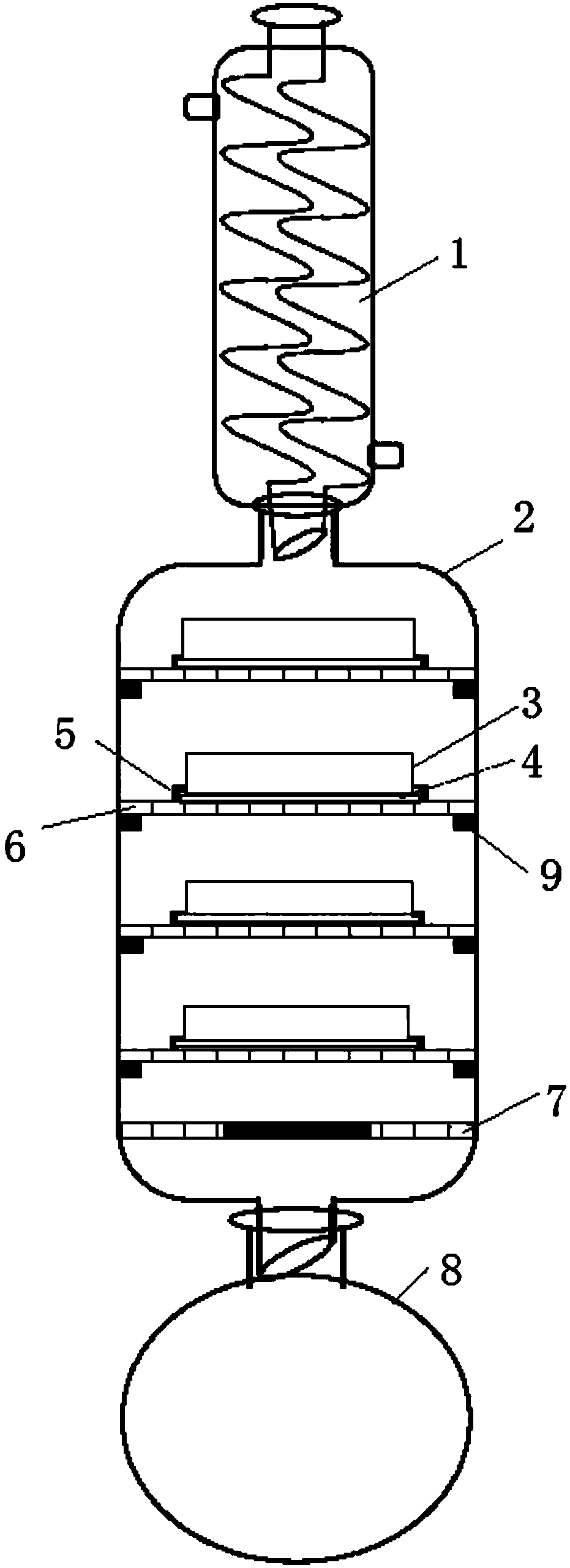

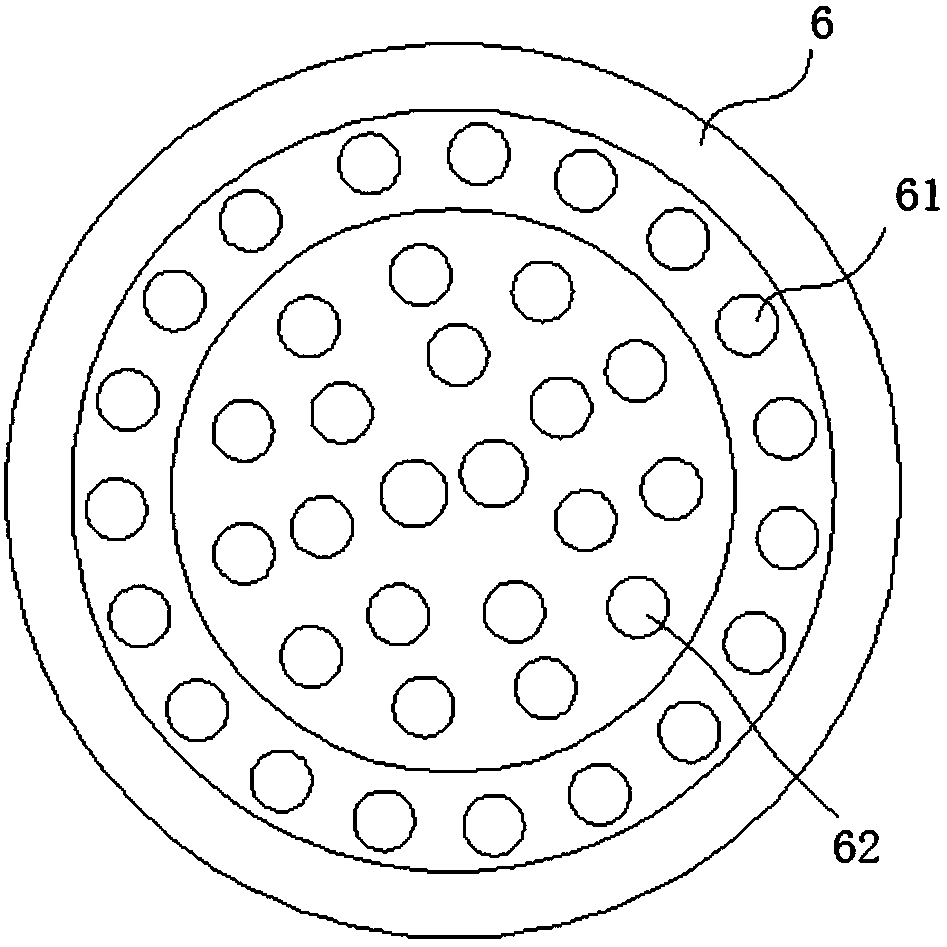

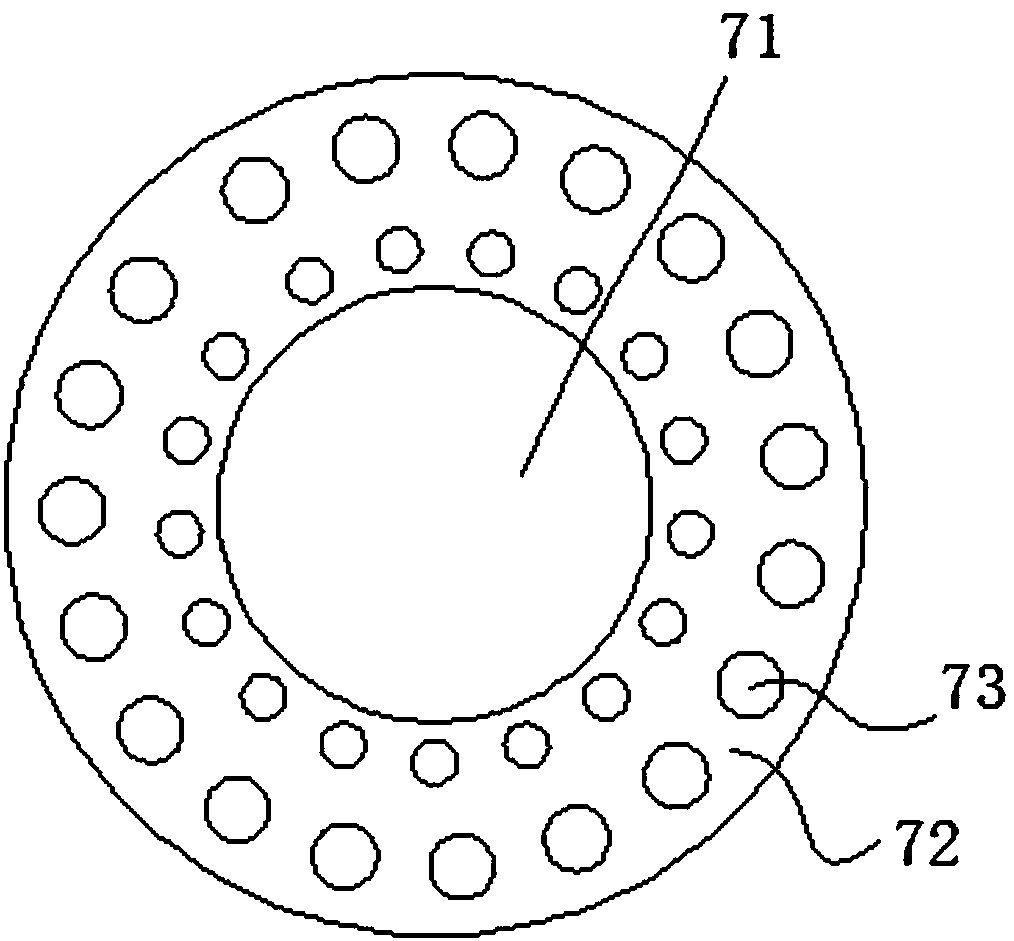

[0018] The embodiment of layered solid-liquid extraction device of the present invention: as Figure 1-Figure 3 As shown, the layered solid-liquid extraction device includes a condenser 1, an extractor 2 and an evaporator 8 arranged up and down. Condenser 1 adopts serpentine condenser. The extractor 2 is provided with four layers of sieve plates 6, and each layer is arranged at intervals up and down. An extraction tank 3 is placed on each sieve plate 6, and the extraction tank 3 is used to contain solid materials. A filter paper 4 is placed between the extraction tank 3 and the sieve plate 6, and the filter paper 4 is laid flat. The sieve plate 6 is provided with a plurality of small holes, the small holes on the part of the sieve plate covered by the extraction tank form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com