Liftable aluminum alloy sections fixing mechanism with convex positioning groove

A technology of aluminum alloy profiles and fixing mechanisms, which is applied to large-scale fixing members, positioning devices, metal processing machinery parts, etc., can solve problems such as fixing troubles and poor effects, and achieve firm fixing, high efficiency, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

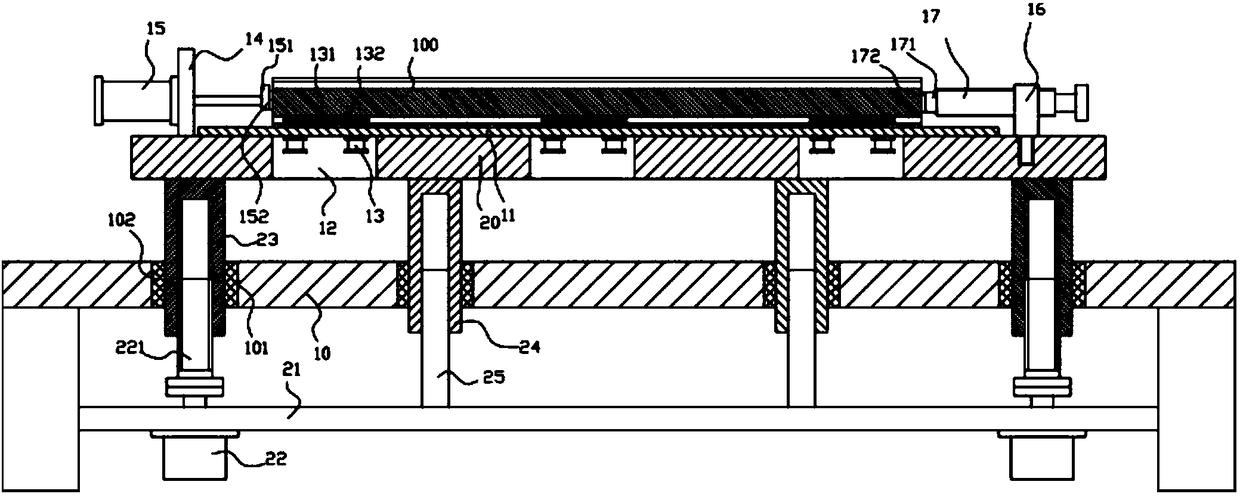

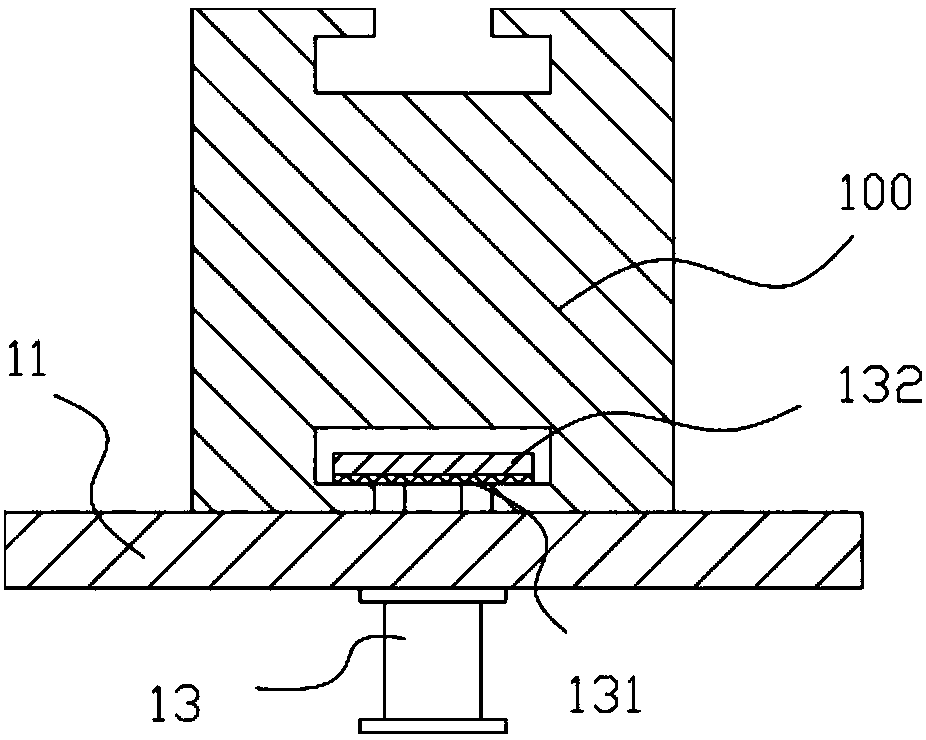

[0018] Example: see Figure 1 to Figure 2 As shown, a lifting and lowering aluminum alloy profile fixing mechanism with a convex positioning groove includes a frame 10 and a lifting main board 20. plate 21, a plurality of lifting motors 22 are fixed on the bottom surface of the horizontal fixing plate 21, the output shaft of the lifting motor 22 passes through the horizontal fixing plate 21 and is connected with a lifting screw 221 through a coupling, and the lifting screw 221 is screwed on the lifting screw sleeve 23 Among them, the lifting screw sleeve 23 is inserted into the vertical through hole 101 provided on the top plate of the frame 10, and the top of the lifting screw sleeve 23 is fixed on the bottom surface of the lifting main board 20;

[0019] The top surface of the lifting main board 20 is fixed with a connecting fixed plate 11, and the lifting main board 20 at the bottom surface of the connecting fixed plate 11 is formed with a plurality of installation through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com