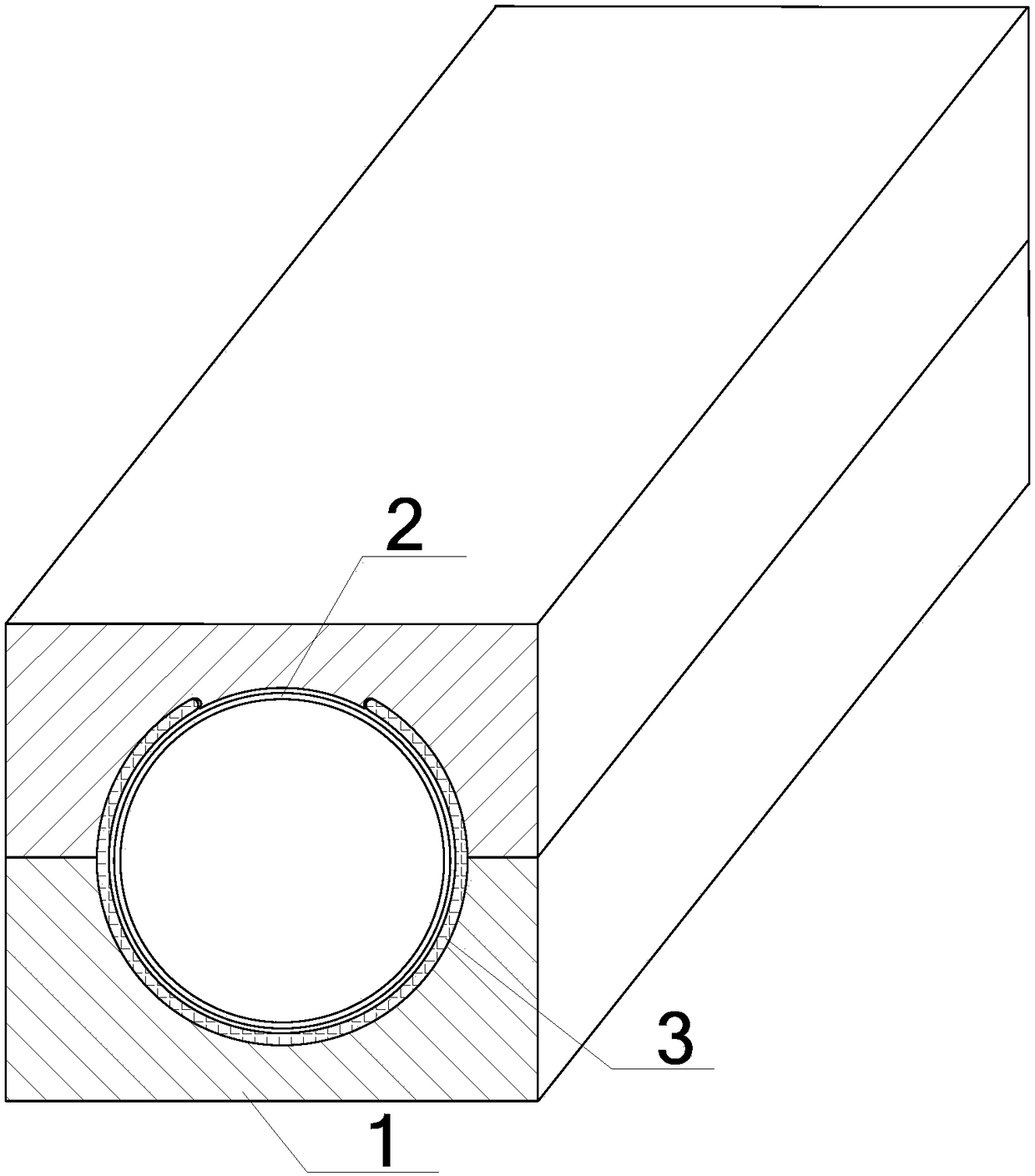

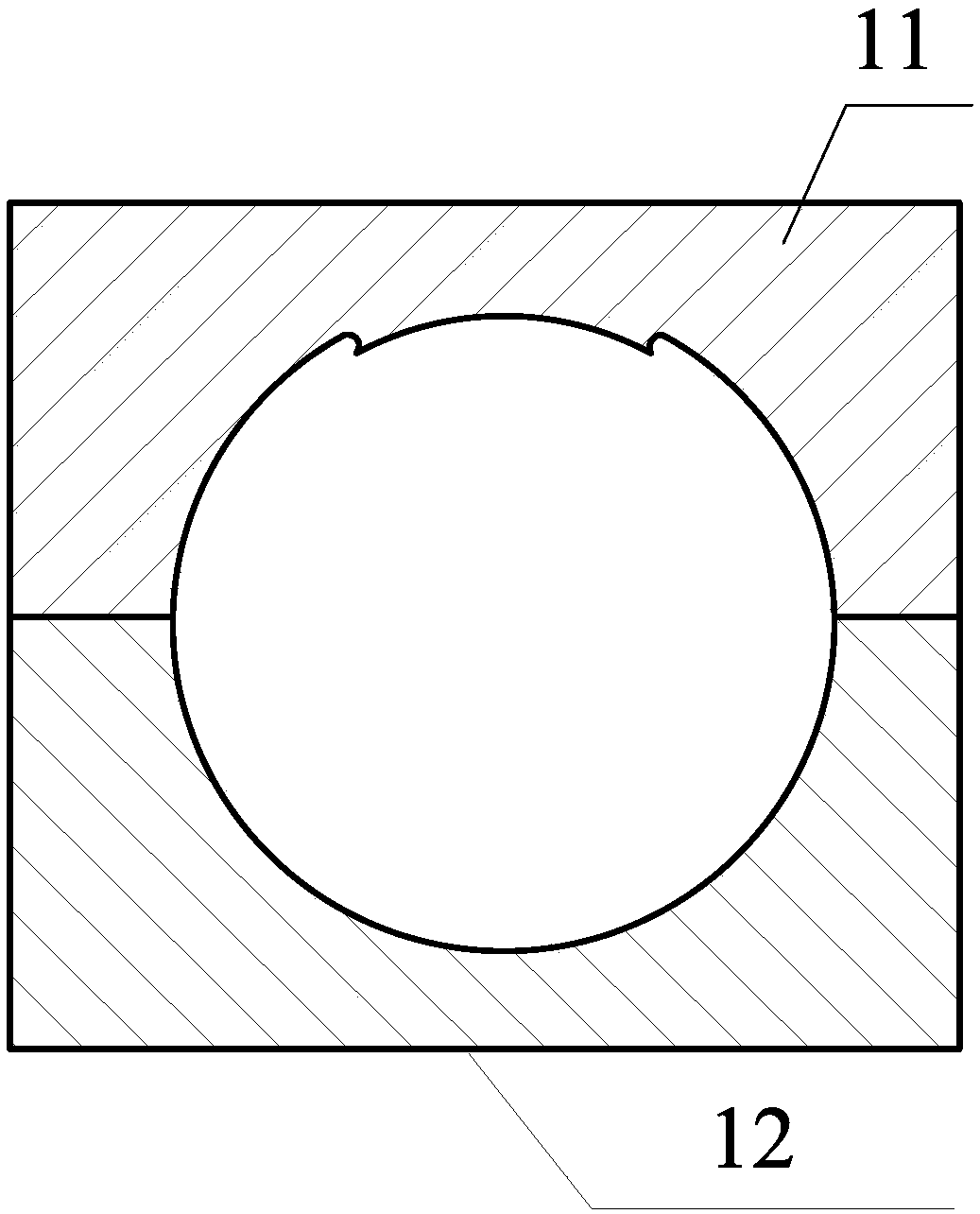

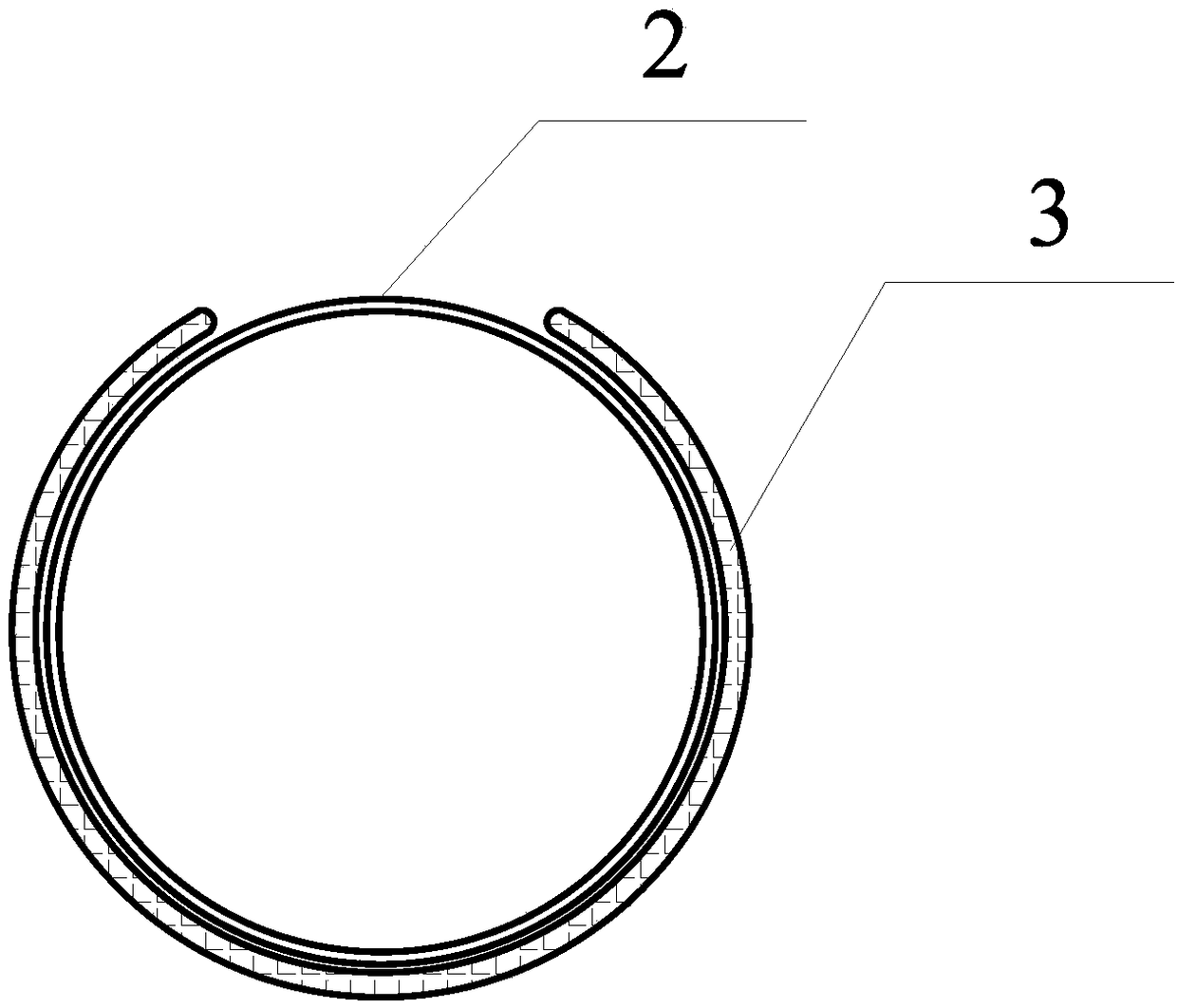

C-shaped-cross-section composite bistable-state shell structure and forming mold

A technology of composite materials and forming molds, which is applied in the field of composite materials processing, can solve the problems of unable to form the edge area of C-shaped cross-section structure, high pressure of air bag, etc., and achieve the effect of low cost, improved product quality and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Glass fiber non-weft cloth / epoxy resin prepreg is used as the material of the C-shaped structure, and the prepreg is laid and molded according to the design. The airbag is inflated and pressurized, and the pressure is controlled at 0.02-0.1bar, and then the prepreg layer is laid on the outer surface of the airbag, and then loaded into the female mold, and the mold is fastened. Gradually heat up to the softening point of the resin, generally at 30-80°C, during which the airbag pressure remains unchanged. After reaching the softening point temperature, continue to pressurize the airbag, increase the pressure to 0.05-0.3bar, maintain it for 5 minutes, release the pressure to the initial pressure, and then pressurize to 0.05-0.3bar. After repeating the above pressurization process 2-5 times, maintain the pressure at 0.1-0.5 bar, and raise the temperature to 130°C, keep the temperature for 120 minutes, then lower the temperature to 80°C, and demould.

Embodiment 2

[0032]Glass fiber non-woven fabric / PA66 prepreg is used as the material of the C-shaped structure, and the prepreg is laid and molded according to the design. The airbag is inflated and pressurized, and the pressure is controlled at 0.02-0.1bar, and then the prepreg layer is laid on the outer surface of the airbag, and then loaded into the female mold, and the mold is fastened. Gradually heat up to the softening point of the resin, generally at 160°C, during which the airbag pressure remains unchanged. After reaching the softening point temperature, continue to pressurize the airbag, increase the pressure to 0.05-0.3bar, maintain it for 5 minutes, release the pressure to the initial pressure, and then pressurize to 0.05-0.3bar. After repeating the above pressurization process 2-5 times, start to raise the pressure to 0.1-0.5 bar, then raise the temperature to 130°C, keep the temperature for 15 minutes, then lower the temperature to below 60°C, and demould.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com