Building engineering sewage and sludge separating and recycling equipment

A technology for sewage sludge and construction engineering, which is used in dewatering/drying/concentrating sludge treatment, sludge treatment, heating water/sewage treatment, etc. and other problems, to achieve the effect of improving utilization rate, reducing sewage discharge and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

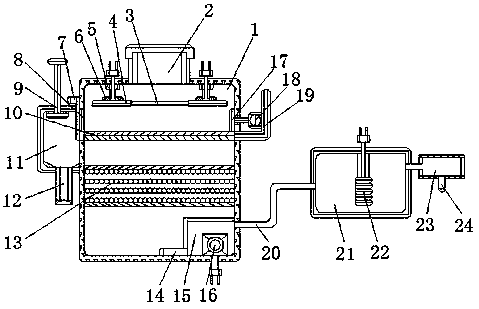

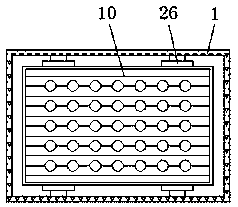

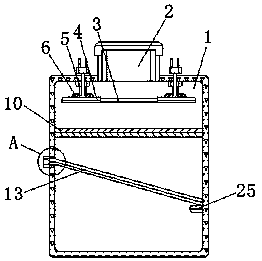

[0022] Embodiment of the present invention: a kind of sewage sludge separation and recycling equipment for construction engineering, as attached Figure 1-4 As shown, there is a main body 1 with a box structure. The top of the main body 1 is provided with a feed port 2. The coincidence of the axes can enhance the connection between the feed port 2 and the main body 1, and under the action of the feed port 2, the material can enter the interior of the main body 1 vertically, and the work efficiency of the device can be improved, and the feeding The inside of the main body 1 below the mouth 2 is provided with a filter plate 10, a filter screen 13, and a sewage discharge system from top to bottom, and an outlet port 8 is provided on the main body 1 on the left side of the filter plate 10, and a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com