Quick cooling method of aluminum profile extrusion on-line quenching process

A technology for rapid cooling and aluminum profiles, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve problems such as inability to perform rapid cooling and ensure the stability of aluminum profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

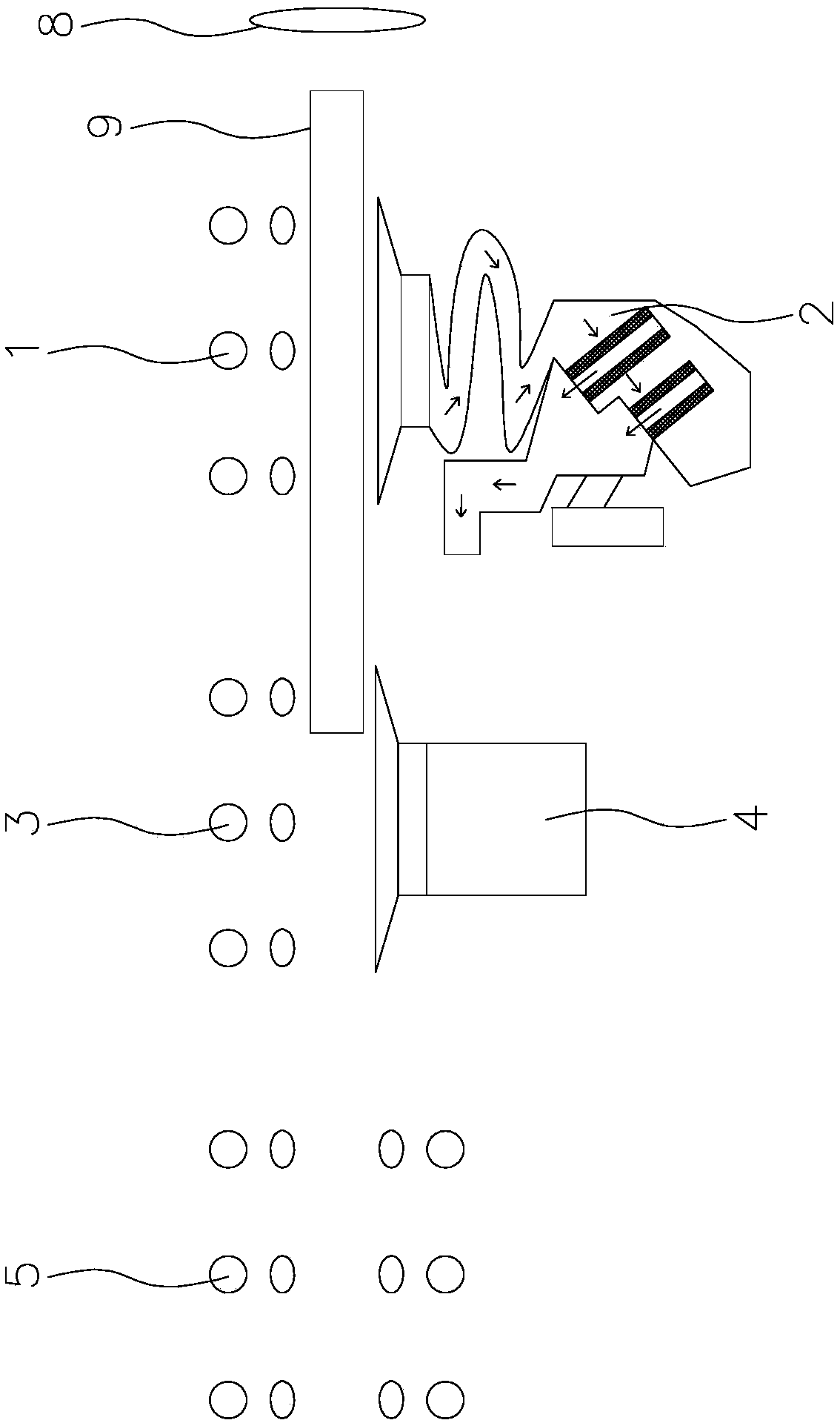

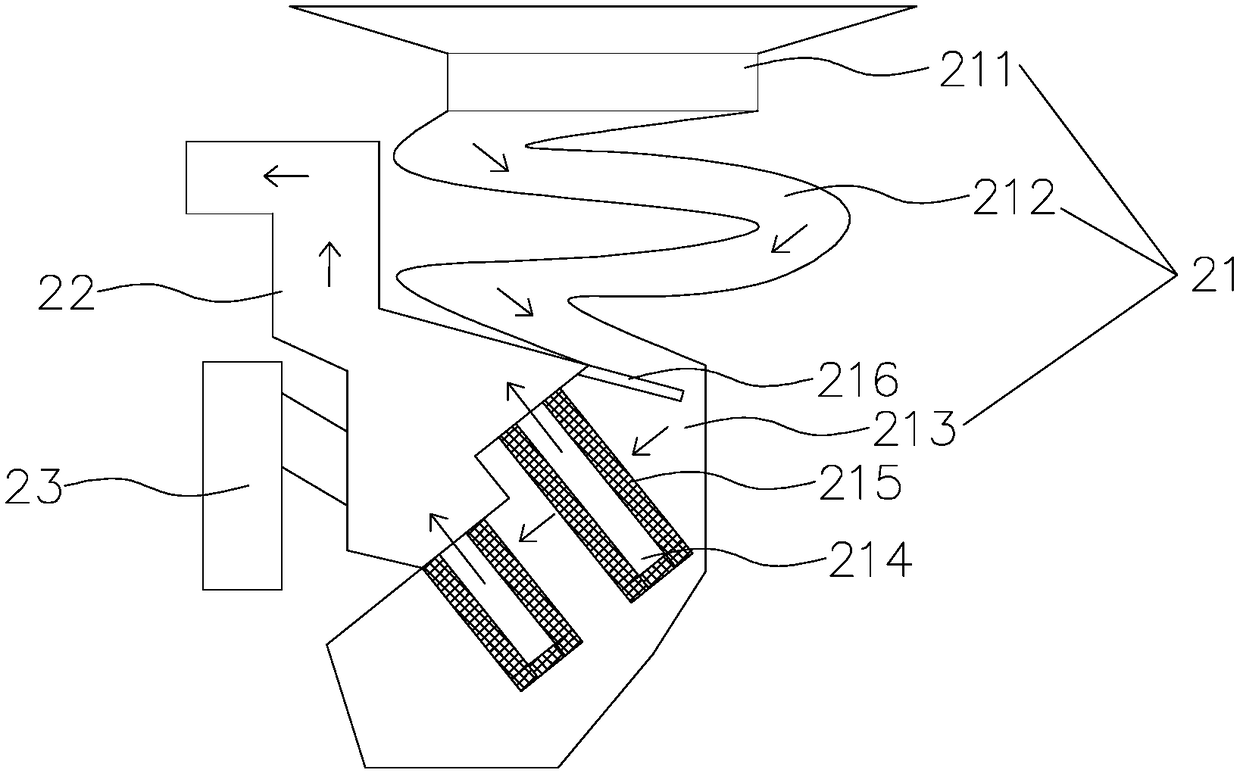

[0017] refer to figure 1 , figure 2 , the present embodiment provides a rapid cooling method for an aluminum profile extrusion on-line quenching process, comprising the following steps:

[0018] In the first step, after the aluminum profile 9 passes through the heating ring 8, it is sent into the first cooling area, and a plurality of first spraying devices 1 are arranged in the first cooling area, and each first spraying device 1 is evenly distributed to form an arc-shaped channel , the particle size of the water mist sprayed by each first spray device 1 is not greater than 10 μm, and a first suction fan 2 for absorbing water mist particles is provided under each first spray device 1 in the first cooling area;

[0019] The second step is then sent to the second cooling area, where a plurality of second spraying devices 3 are arranged in the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com