Prefabricated reinforced structure and rammed wall for improving the integrity of rammed wall

An integral, rammed earth wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problem of not retrieving the existing technology, avoid unevenness, improve lateral bearing capacity, save materials and labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and by specific embodiment the present invention is described in further detail, following embodiment is descriptive only, is not limiting, can not limit protection scope of the present invention with this.

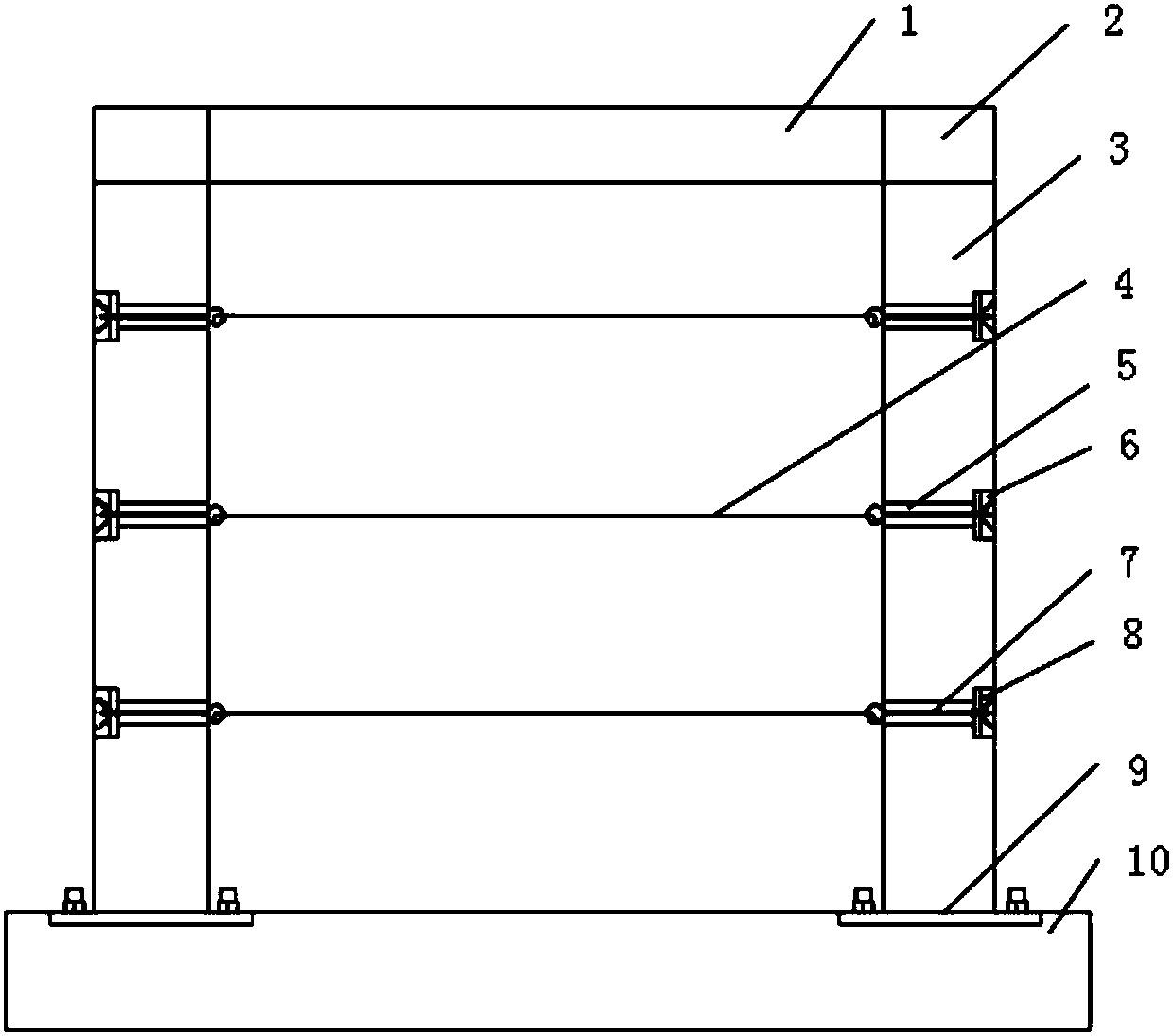

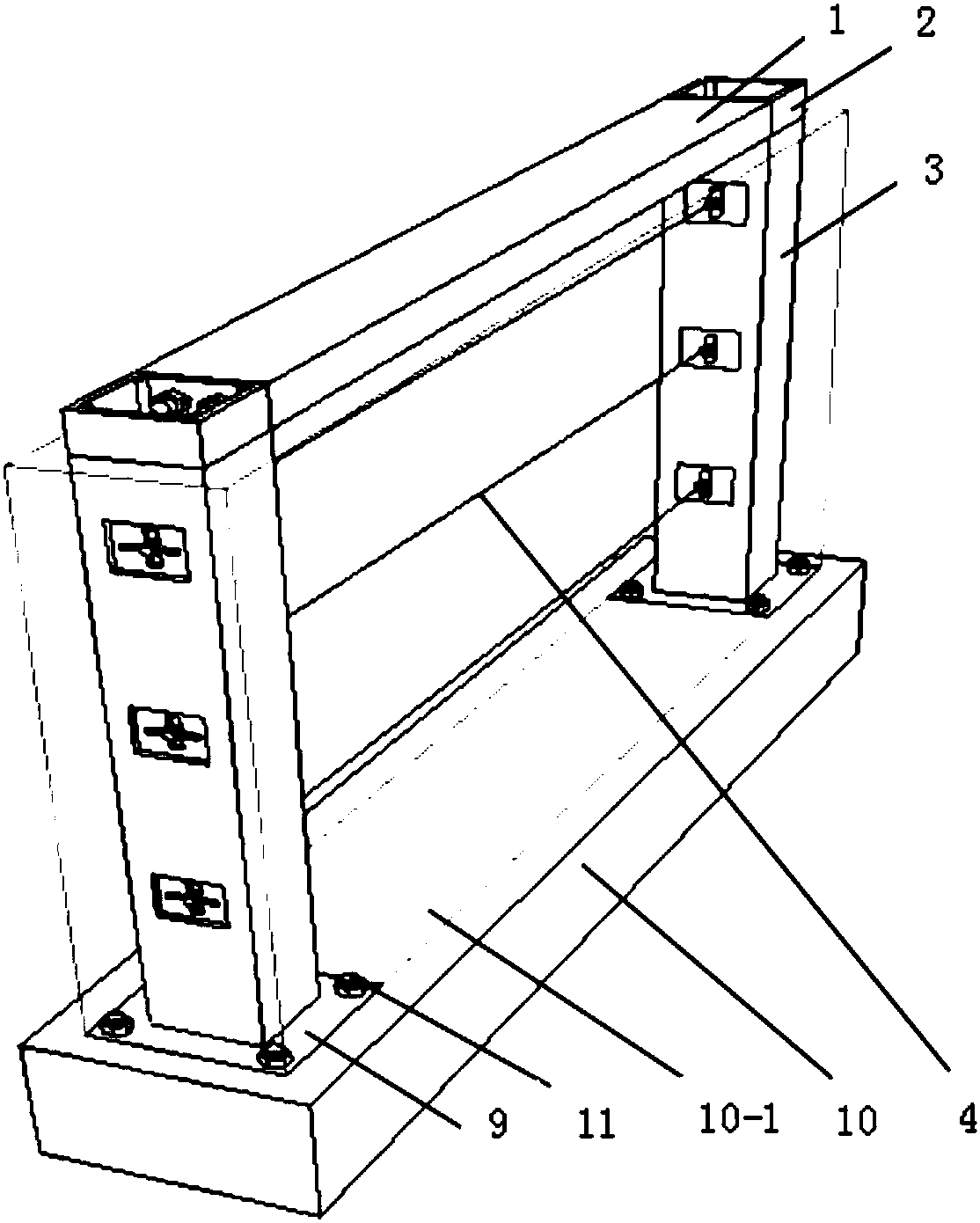

[0029] A prefabricated reinforced connection structure to improve the integrity of rammed earth walls, see Figure 1-5 , its innovative point is that it consists of the following parts:

[0030] Including the wall foundation 10, a positioning groove 10-1 is reserved on the upper surface of the wall foundation, and foundation embedded bolts 11 are reserved near the two ends in the positioning groove.

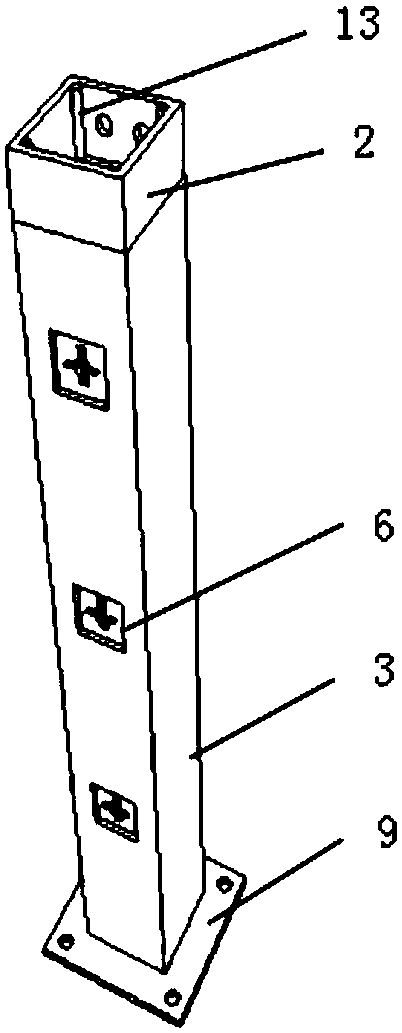

[0031] Including two prefabricated structural columns 3, the two prefabricated structural columns are column structures welded with bottom end plates, bolt holes are reserved on the bottom end plates, and a steel joint 2 is welded at the upper ends of the two prefabricated structural columns. The bottom end plates of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com