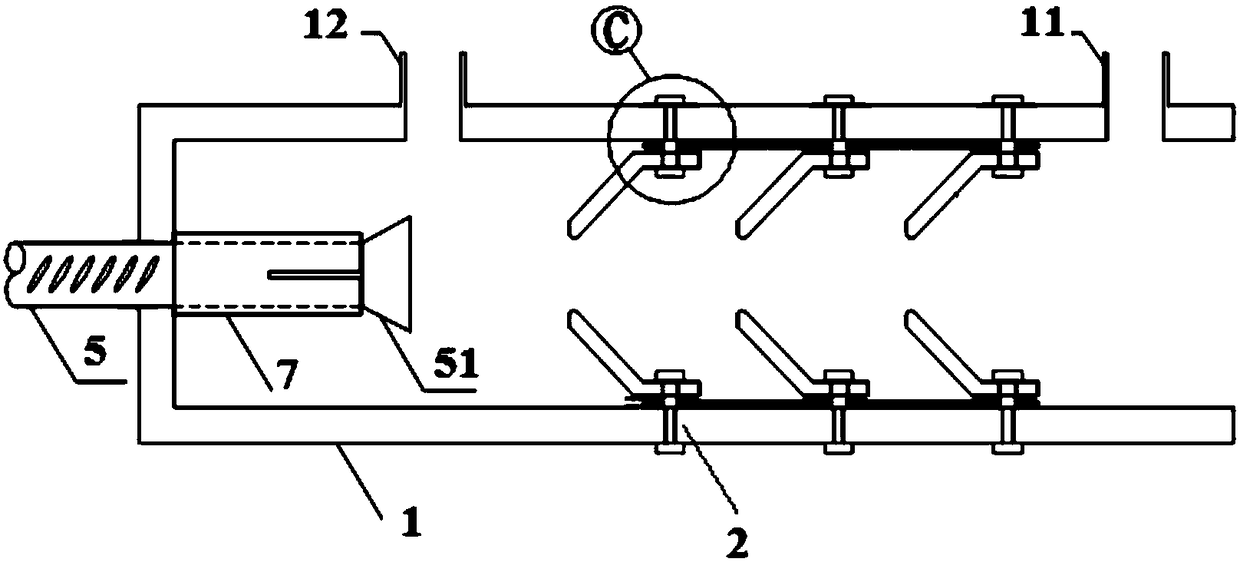

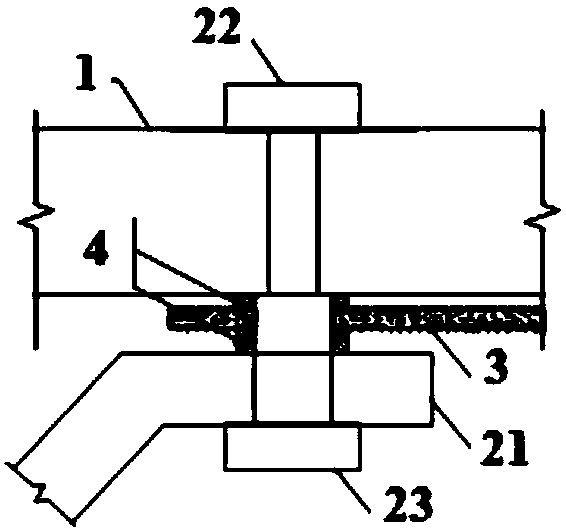

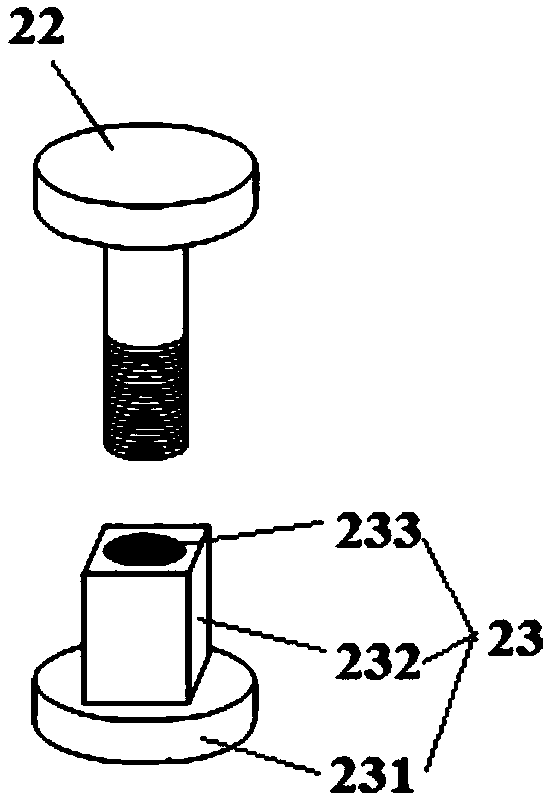

Mixed type grouting sleeve and prefabricated shear wall thereof

A grouting sleeve and hybrid technology, applied in the direction of walls, structural elements, building components, etc., can solve problems such as poor grouting quality, reduce the reserved length, shorten the length of the sleeve, and improve the integrity and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Present embodiment is to the shear wall of the present invention ( Figure 8b ) and traditional shear walls ( Figure 9 ) connection performance for finite element simulation experiments:

[0061] Wherein the wall of the grouting sleeve of the traditional shear wall is corrugated, and the connecting steel bar (the first steel bar 5 ) is connected with the sleeve by threads.

[0062] The length of the sleeve in the shear wall of the present invention and the traditional shear wall is 10cm, and the connecting steel bars in the wall are HRB steel bars with a diameter of 12cm.

[0063] The most ideal failure phenomenon in the general shear wall connection is that the connecting steel bar is broken during the pull-out test, but the connecting sleeve and its grouting material are not damaged, and the steel bar does not slip in the sleeve to cause the connection to fail. The experimental results found that the traditional shear wall failed before the connected steel bar (the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com