Double-position telescopic positioning mechanism for automobile inspection tool

A telescopic positioning and positioning mechanism technology, applied in the direction of manufacturing tools, using mechanical devices, mechanical measuring devices, etc., can solve the problems of poor measurement accuracy, poor overall intuitiveness, and narrow application range, and achieve good limit positioning effect and application range. Narrow, overall applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

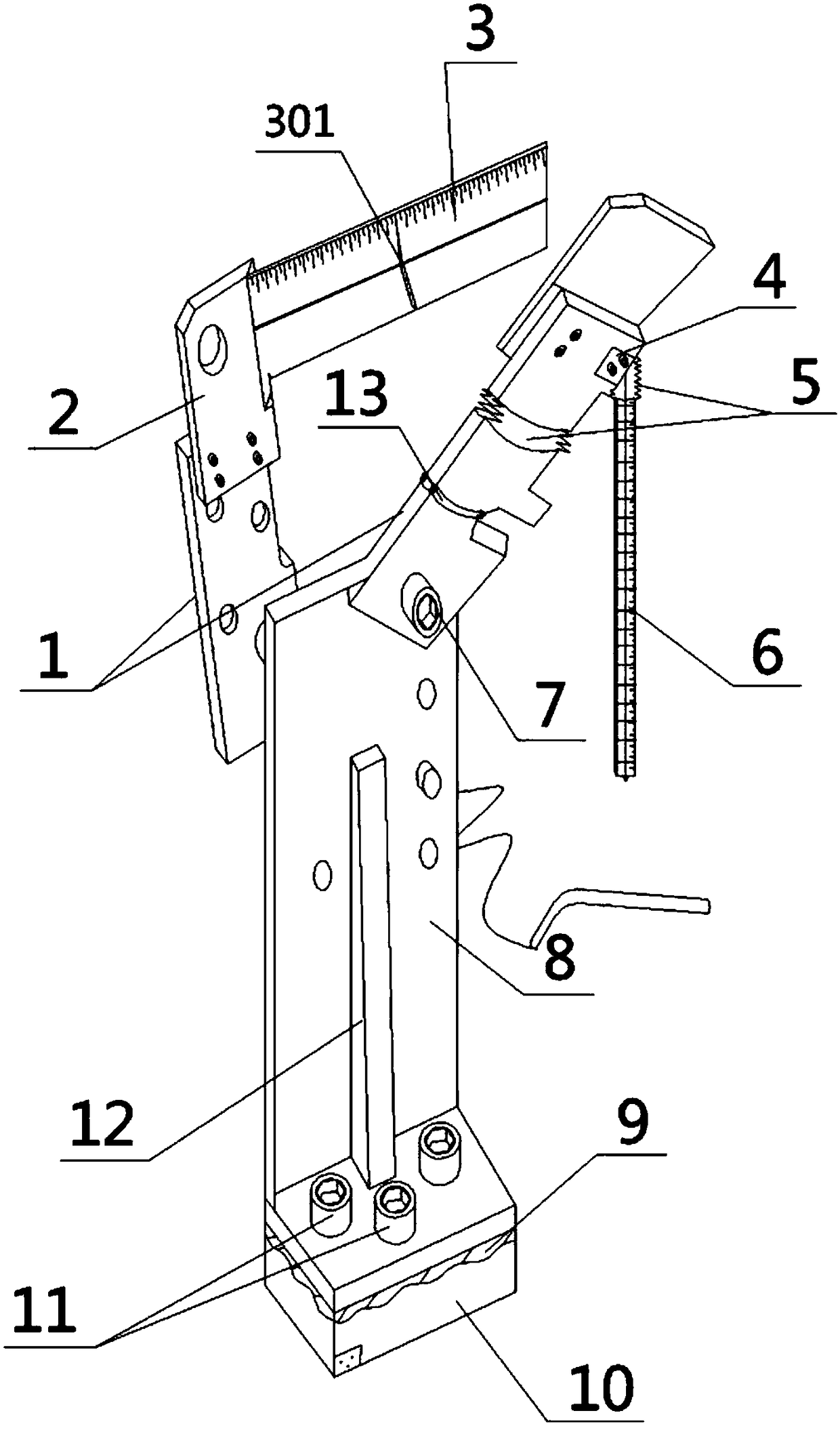

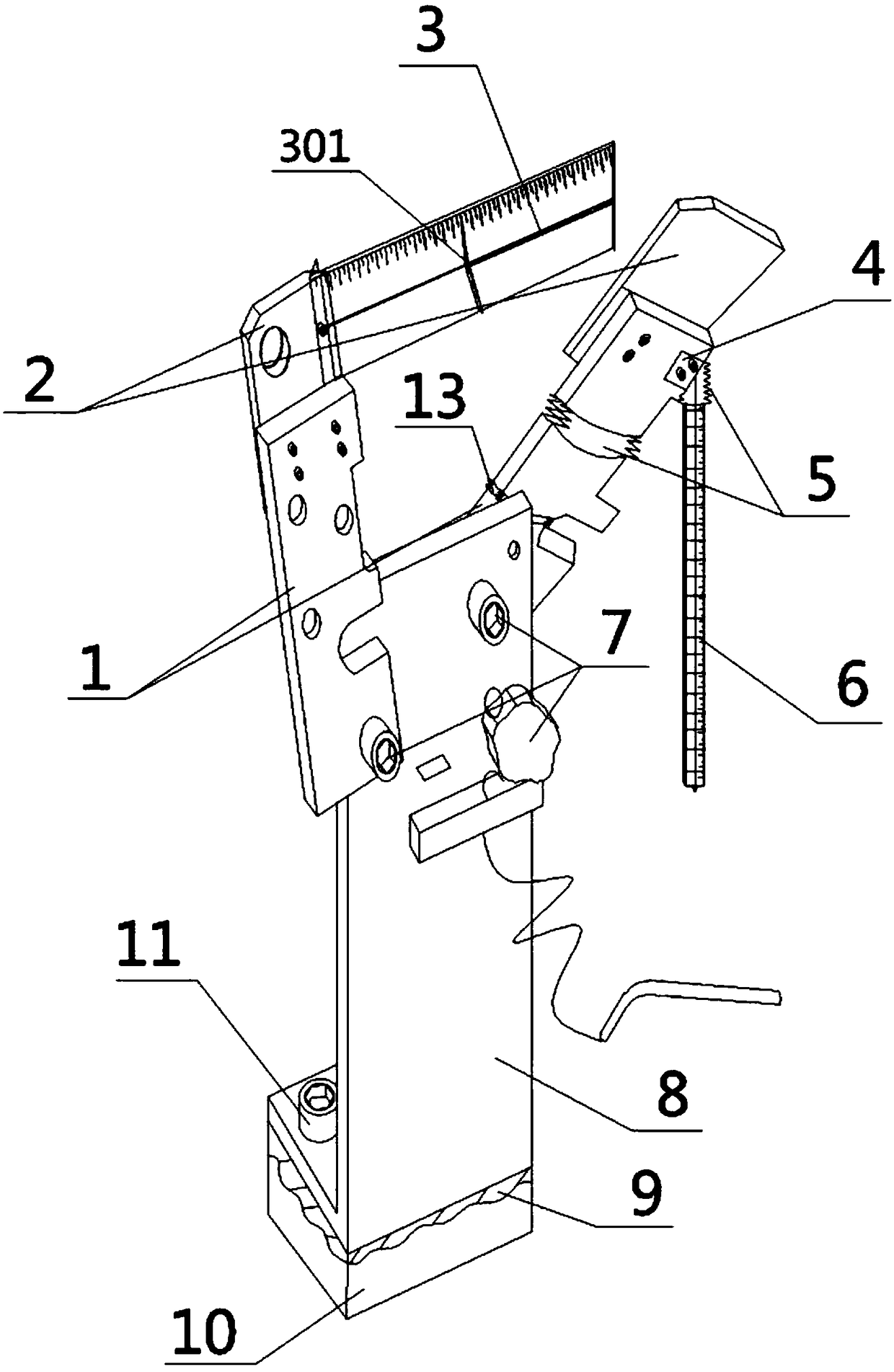

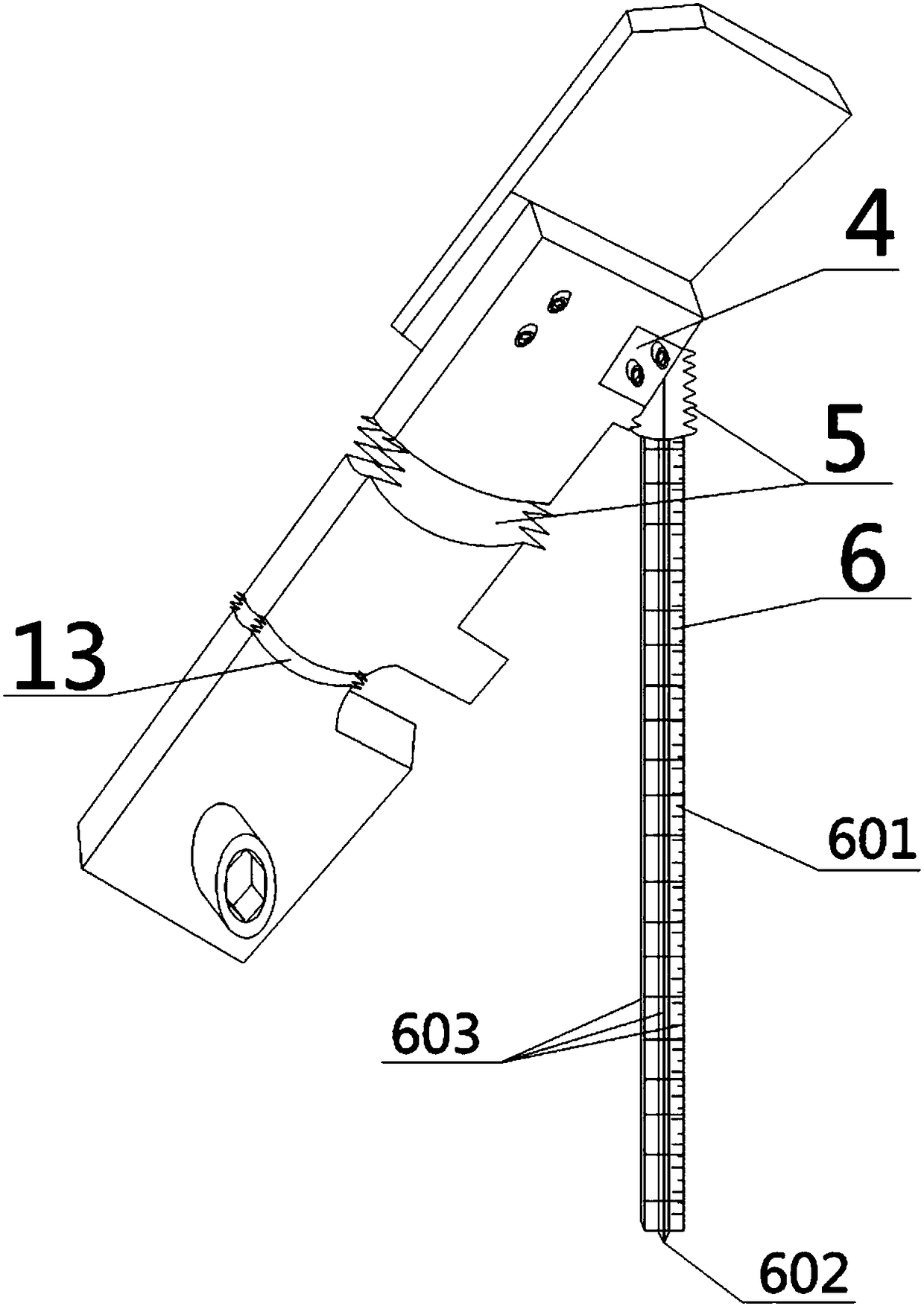

[0014] Referring to the accompanying drawings, a double-position telescopic positioning mechanism for automobile inspection tools is characterized in that it includes a double-position telescopic mechanism and an overall positioning mechanism. The double-position telescopic mechanism includes a limit plate (1), a transverse positioning plate (2), a transverse ruler ( 3), clamping plate (4), longitudinal ruler (6), telescopic connection (5) and position adjustment fixing bolt (7), the overall positioning mechanism includes L-shaped vertical plate (8), magnet disc (10), insulating pad ( 9), the oblique plate (12) and the fixing part (11), the two-position telescopic mechanism is installed on the overall positioning mechanism, and the oblique plate (12) in the overall positioning mechanism is installed on the L-shaped vertical plate (8) At the L-shaped bend, the fixture (11) is installed on the upper surface of the L-shaped vertical plate (8) bottom surface, and the magnet disc (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com