Method and device for locating leakage position of HDPE membrane through stress wave

A technology of stress wave and position coordinates, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems that the equipment cannot meet the requirements of contamination before detection, low resolution, etc. , to achieve the effect of improving the resolution and reducing the difficulty of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

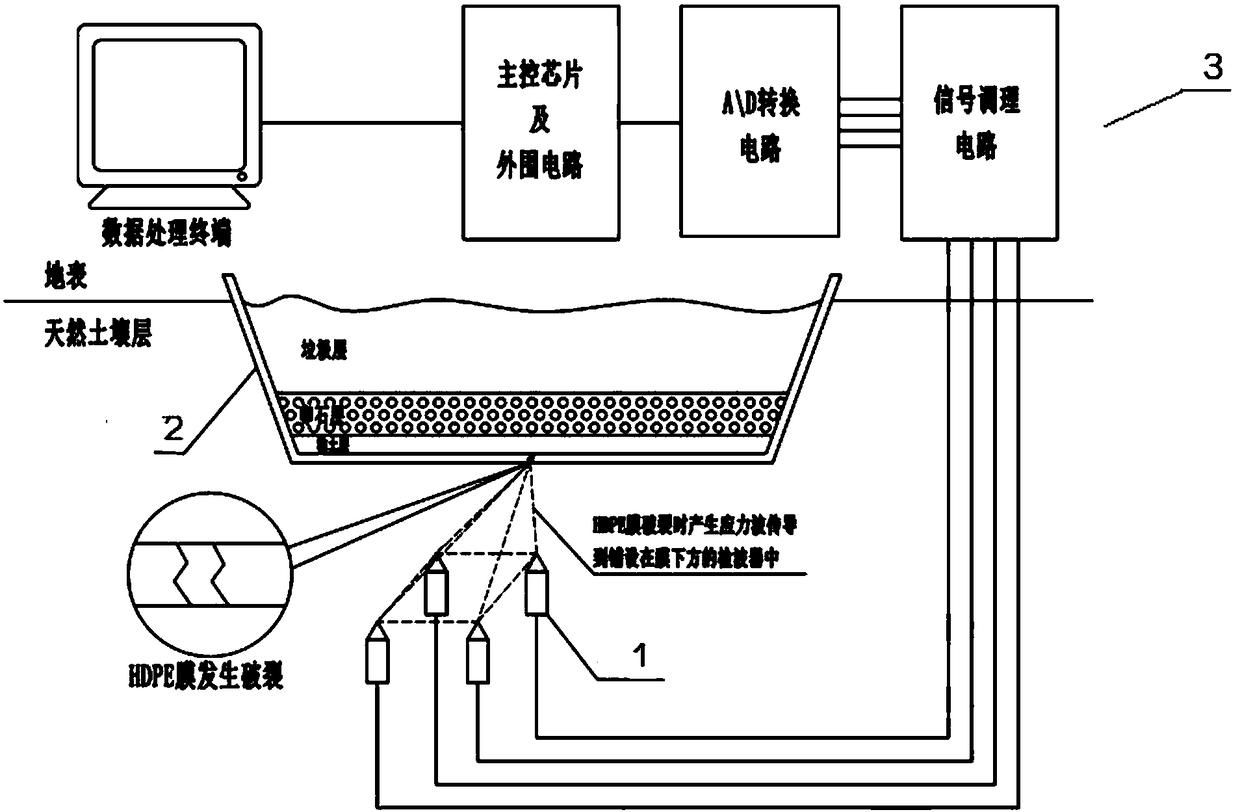

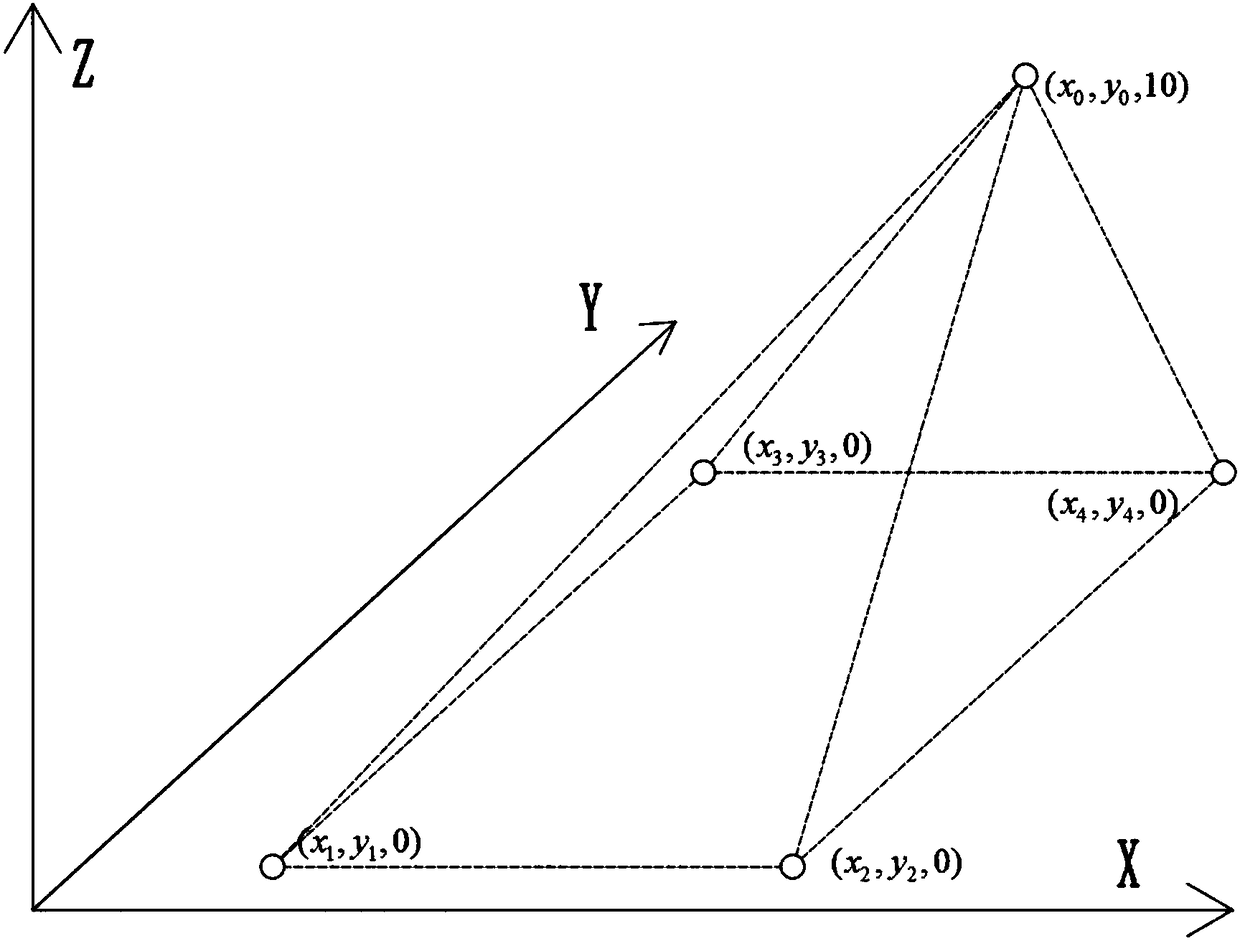

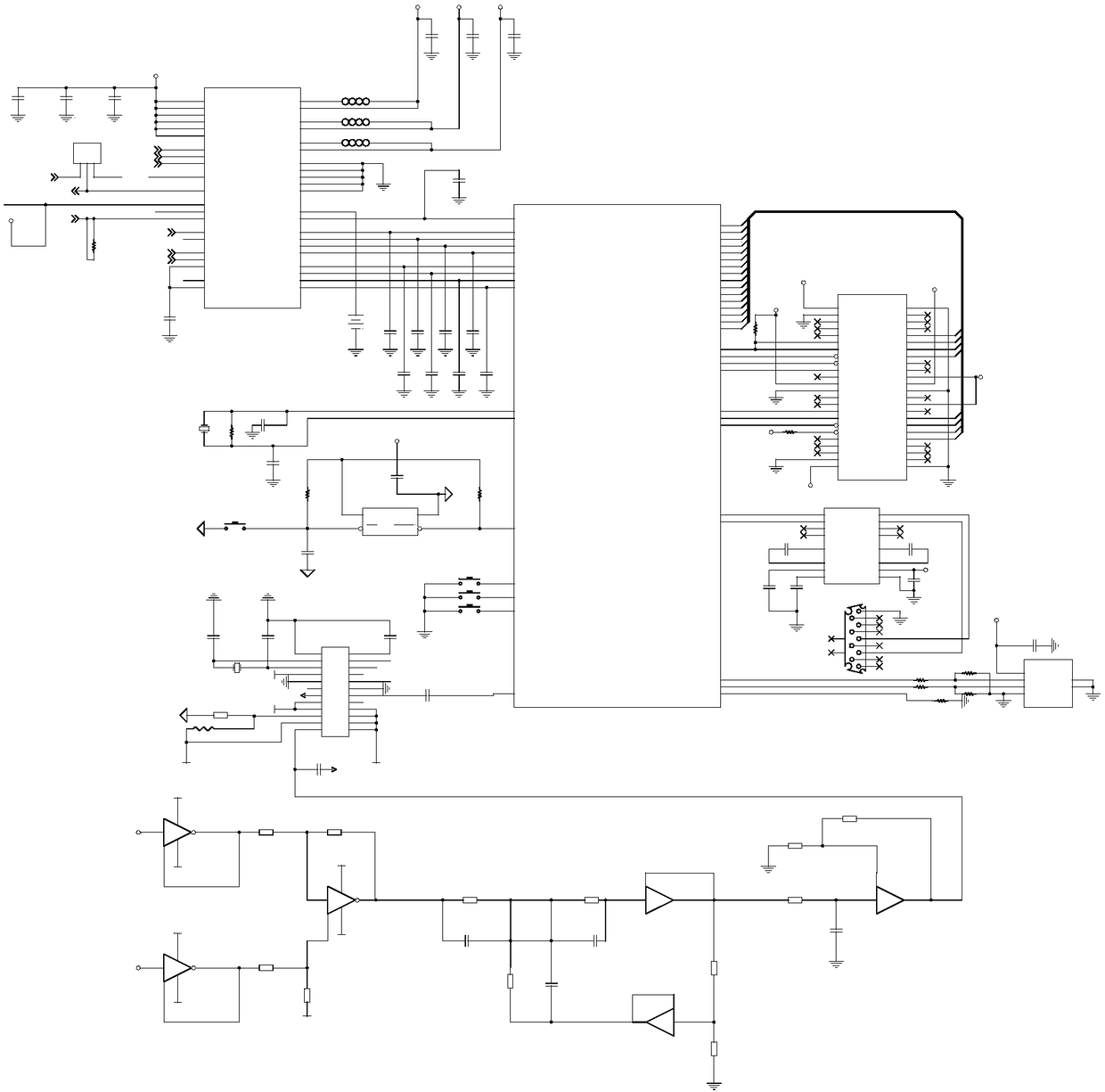

[0051] A method and device for locating the leakage position of HDPE film 2 by using stress wave of the present invention is to use stress wave testing technology to perform real-time leakage location for the anti-seepage layer (HDPE film) of the landfill. Due to the uneven subsidence of the foundation and the corrosion of landfill seepage, the HDPE membrane 2 laid under the pebble layer will be randomly broken, and then different forms of stress waves will be generated. In this method, the vibration detectors are laid in the soil layer under the HDPE membrane 2 in a certain arrangement, and the arrival time of the stress wave is monitored by the detectors, so as to determine the moment and the spatial position of the stress wave generated by the HDPE membrane 2, and the stress The wave is modulated and amplified, and the clutter is filtered out and sent to the information processing terminal for analysis. The invention patent can not only solve the problem that the traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com