Method for measuring device installation accuracy of spacecraft

A technology for precision measurement and equipment installation, which is applied in space navigation equipment, space navigation equipment, machine/structural component testing, etc. It can solve problems such as inconsistency in installation precision, ensure consistency, ensure accuracy and effectiveness, and avoid non-compliance Effect

Active Publication Date: 2018-08-17

BEIJING SPACE TECH RES & TEST CENT

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a method for measuring the installation accuracy of spacecraft equipment to solve the problem that the installation accuracy of the equipment on the cabin of the spacecraft is inconsistent between the ground and the orbit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

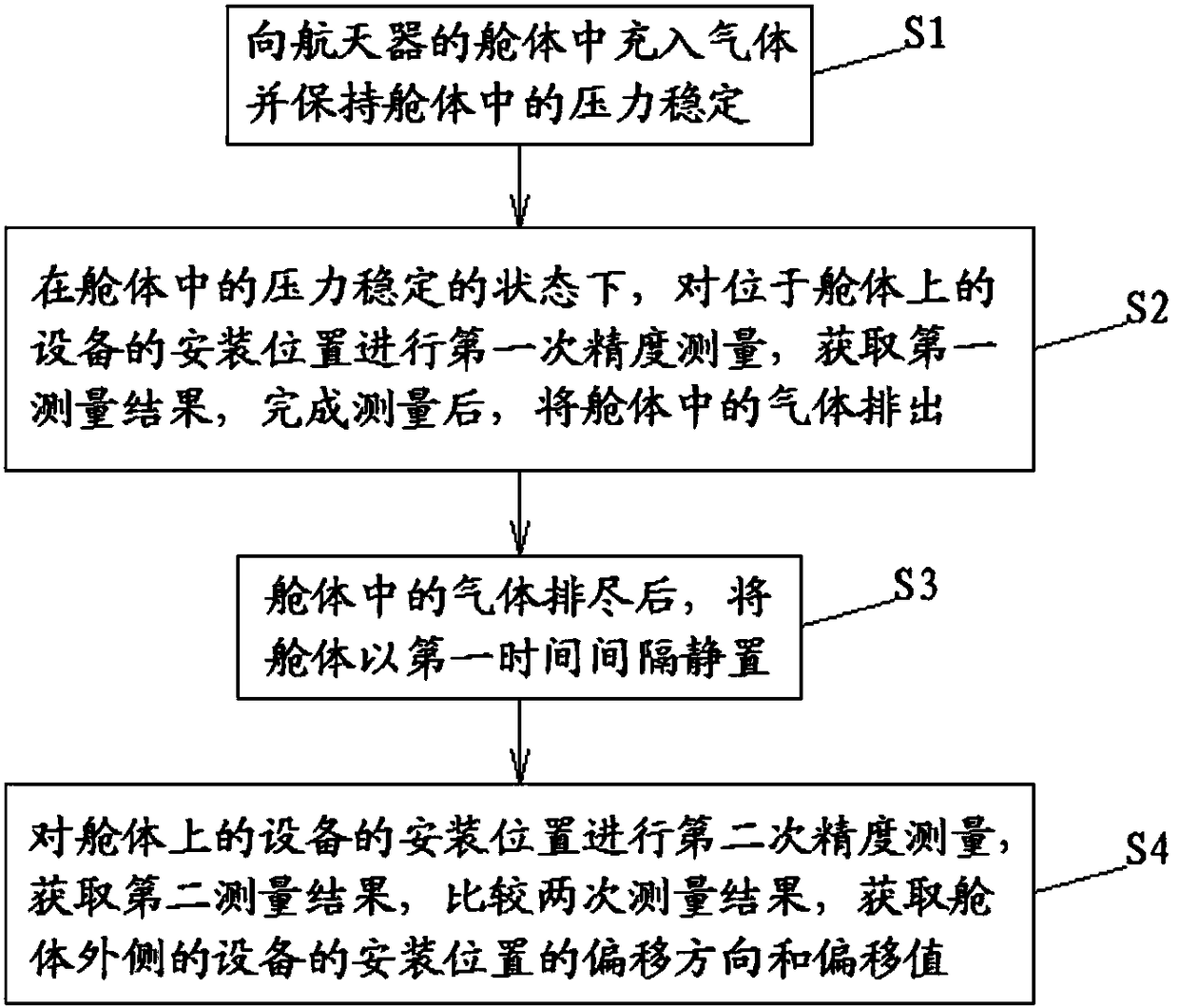

[0033] Such as figure 1 As shown, according to an embodiment of the present invention, a method for measuring the accuracy of equipment installation of a spacecraft of the present invention includes:

[0034] S1. Inflate gas into the cabin of the spacecraft and keep the pressure in the cabin stable;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

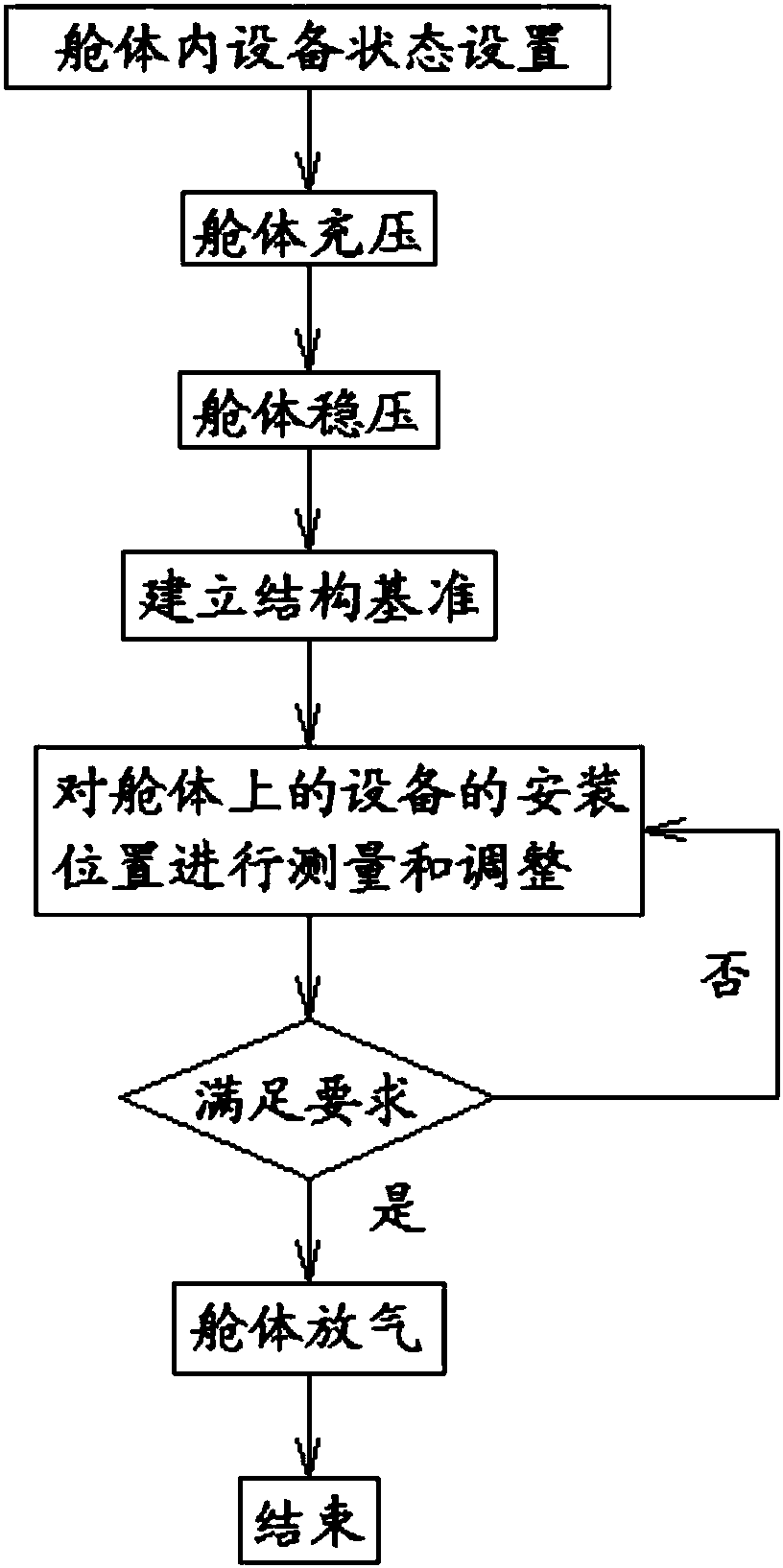

The invention relates to a method for measuring the device installation accuracy of a spacecraft. The method comprises: S1, a cabin of a spacecraft is filled with gas and the pressure in the cabin iskept to be stable; and S2, while the pressure in the cabin is stable, first-time accuracy measurement is carried out on a mounting position of a device on the cabin to obtain a first measurement result and then gas in the cabin is exhausted after measurement is completed. During the ground measurement process, the space pressure environment of the spacecraft is simulated and the gas is led into the cabin, so that the presses inside and outside the cabin of the spacecraft are kept to be one standard atmospheric pressure and thus the state of the cabin of the spacecraft is consistent with the state of the cabin of the spacecraft in actual space flight; and because of the accuracy measurement of the installation position of the device outside the spacecraft cabin, the deviation of the measurement accuracy caused by the different pressure environment factors is eliminated, so that the installation accuracy of the device on the cabin on the ground is consistent with that of the device on the cabin in an in-orbit state.

Description

technical field [0001] The invention relates to a method for measuring equipment installation accuracy, in particular to a method for measuring equipment installation accuracy for spacecraft. Background technique [0002] During the in-orbit flight of a spacecraft, various sensors are needed to complete related tasks, such as rendezvous and docking, on-orbit maintenance, etc. In order to ensure the accurate completion of the task, various sensors must meet the installation accuracy requirements during the final assembly of the spacecraft, which can be achieved by the fine measurement of the ground assembly, but the pressure environment inside and outside the sealed compartment during the final assembly fine measurement process is different from the on-orbit environment. Similarly, the shell structure of the sealed compartment is partially deformed, which causes the installation accuracy of the equipment to change. The installation accuracy of the equipment that meets the re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M99/00G01M13/00B64G1/00

CPCB64G1/00G01M13/00G01M99/00

Inventor 杨宏刘晓震郝平任长伟任春珍田恩杰苏南方杰田政谷巍

Owner BEIJING SPACE TECH RES & TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com