Feed pump fault detection method based on multiscale principal component analysis

A technology of principal component analysis and fault detection, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of little research on fault detection technology and detection equipment, and stay in long-term itinerant detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

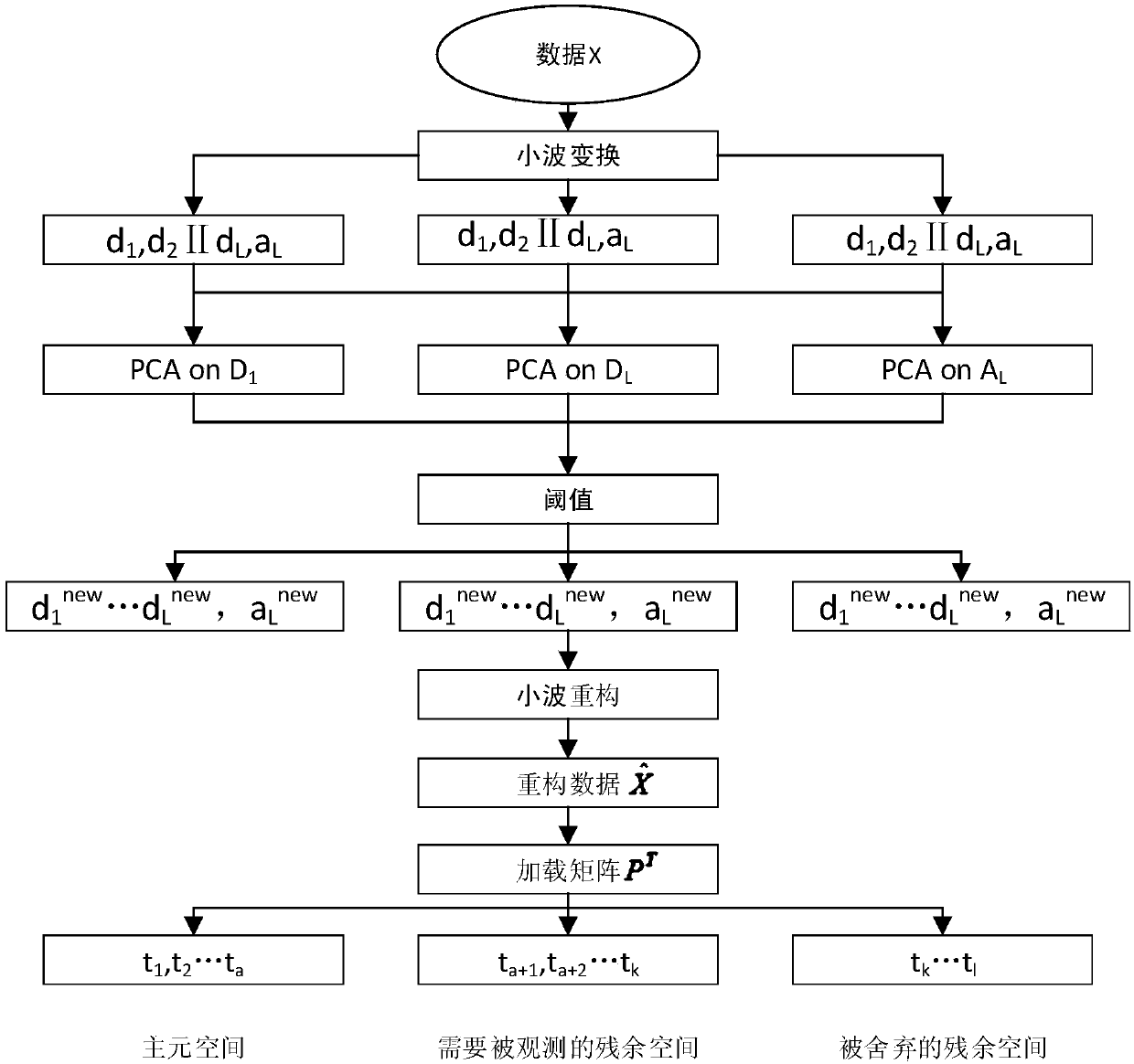

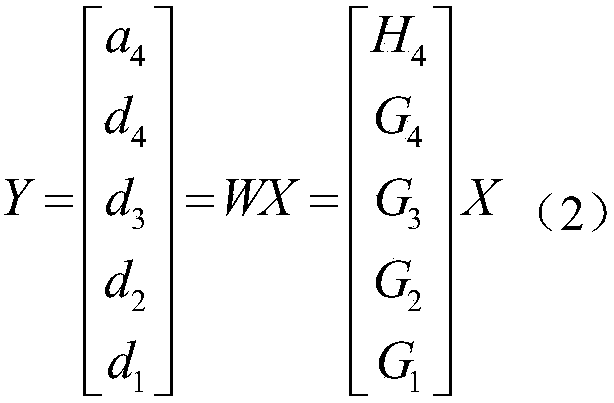

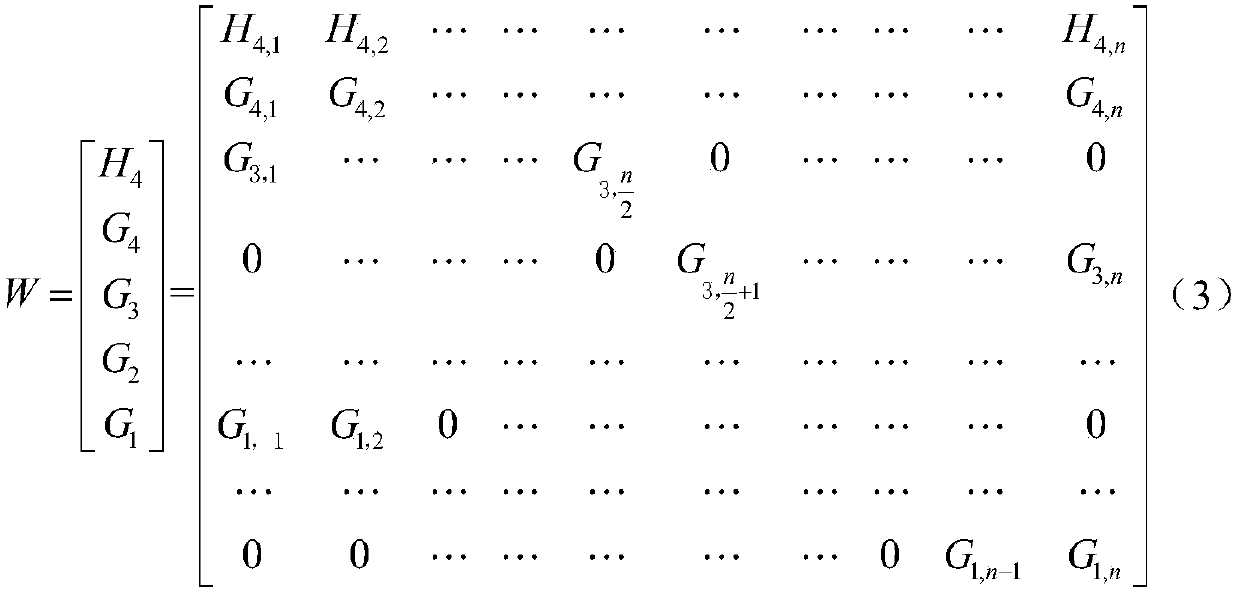

[0079] A kind of water pump fault detection method based on multi-scale principal component analysis method (MSPCA) of the present invention, utilizes discrete wavelet transform to decompose the variable data of collection, utilizes principal component analysis method to determine the wavelet coefficient in each scale, and then Select the coefficients greater than a specific threshold to generate a multi-scale model; use the principal component analysis method to model the new statistics, and calculate T respectively 2 Statistics and Q statistics, when one of the statistics exceeds the threshold, a fault alarm is issued. Compared with the traditional statistical method based on a single scale, the present invention extracts more state information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com