Anti-counterfeit and pressure-sensing transfer printing label and preparation method thereof

A pressure transfer printing and labeling technology, which is applied in the field of anti-counterfeiting pressure-sensitive transfer printing labels and its preparation, can solve the problems of inability to realize digital intelligent anti-counterfeiting, wasteful use of film materials, and high production costs, so as to shorten the production cycle and reduce environmental pollution. Pollution, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

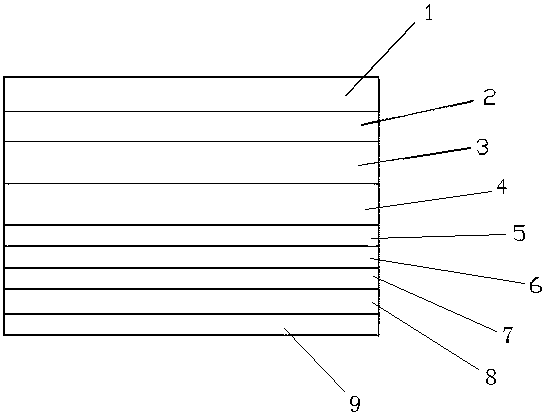

[0022] An anti-counterfeiting pressure-sensitive transfer label, comprising a first printing layer 1, a first adhesive coating layer 2, a transparent film layer 3, a first adhesive layer 4, a peeling layer 5, a second Adhesive coating layer 6, second printing layer 7, second adhesive layer 8 and carrier substrate layer 9; one side of the release layer 5 is the adhesive surface, through the first adhesive layer 4 and the transparent film layer 3 Adhesive as a whole; the other side surface is the peeling surface.

[0023] Wherein, irregular fine lines are distributed on the peeling surface of the peeling layer 5 . The second printing layer 7 is provided with an anti-counterfeiting marking area, and the anti-counterfeiting marking area is provided with colored latex paint and organic particles, and the organic particles are adhered to the anti-counterfeiting marking area through the colored latex paint to form a two-dimensional code pattern of the anti-counterfeiting marking. Bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com