Beam forming directional microphone

A beamforming and directivity technology, applied in the field of beamforming directional microphones, can solve the problems of inability to control the directivity, the physical structure does not change, and the size of the microphone increases, so as to improve the speech recognition rate and reduce fixed noise. , the effect of reducing ambient noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

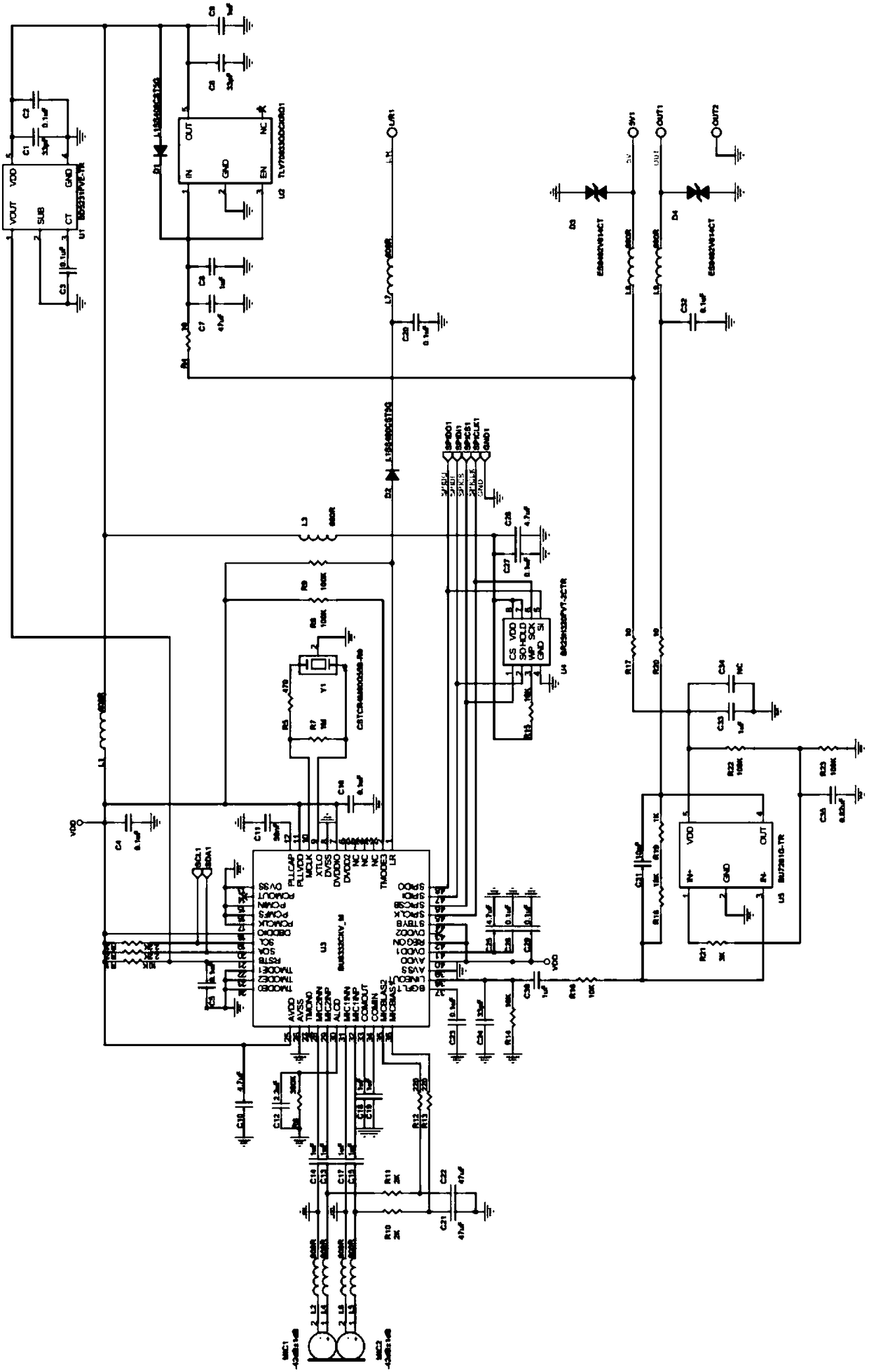

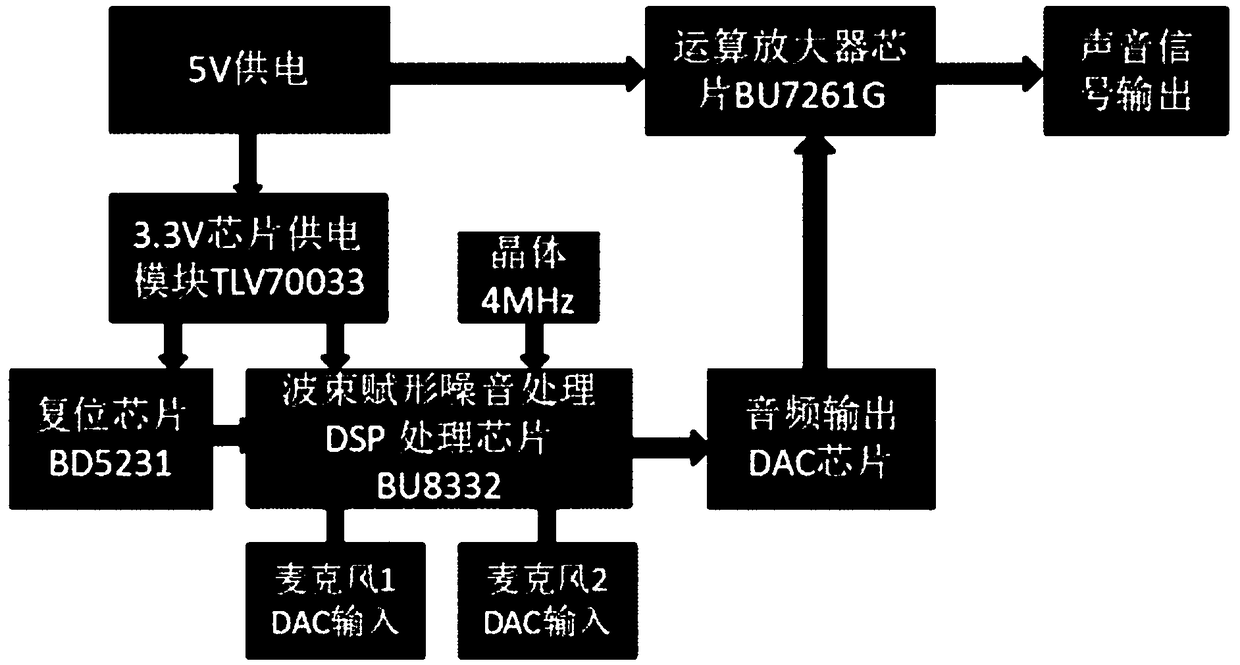

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

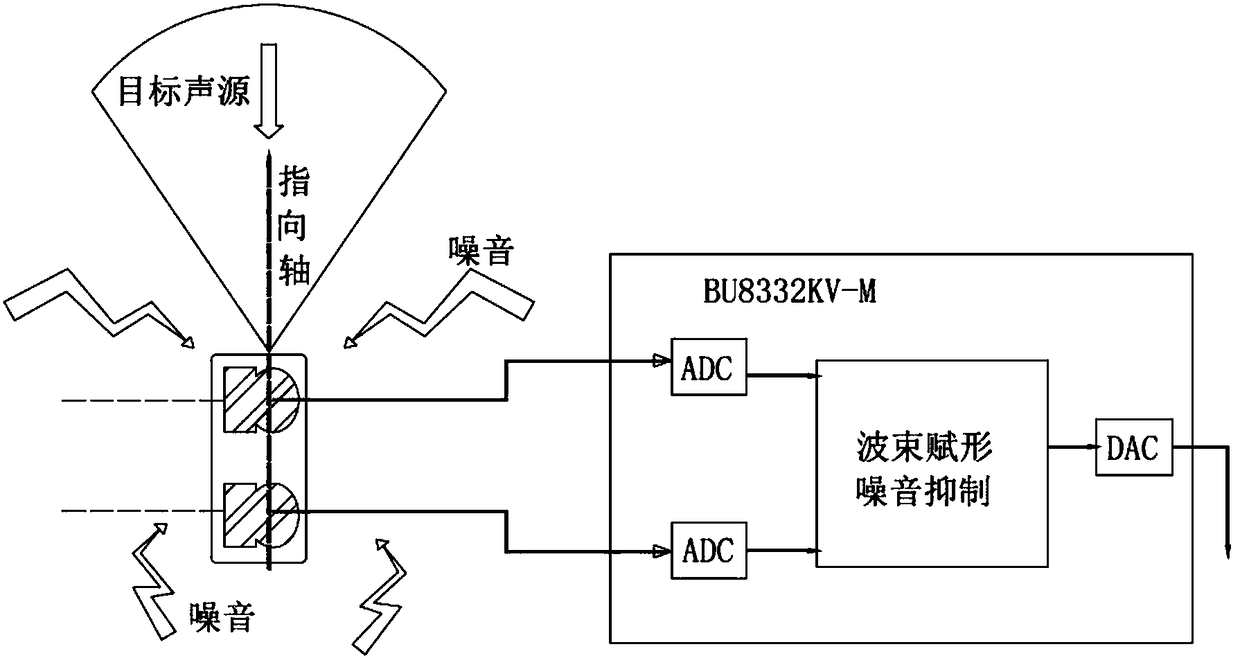

[0021] combined with Figure 1-2 A beam-forming directional microphone, using beam-forming technology to form directivity, turning the pointing axis to the direction of the sound source, including a beam-forming noise processing DSP processing chip, which is connected to two non-directional microphone DAC inputs , the processing chip is provided with a crystal 4MHz crystal oscillator, the processing chip is also provided with a reset chip control connection, the processing chip and the reset chip are powered by a 3.3V chip power supply module, and the 3.3V chip power supply module is also connected to a 5V power supply, The 5V power supply also supplies power to the operational amplifier chip to provide sound signal output at the same time, and the processing chip is connected to the aforementioned ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com