Self-cleaning food processing machine

A food processing machine and self-cleaning technology, which is applied to cleaning hollow objects, cleaning methods and utensils, household utensils, etc., can solve the problems that the area is difficult to be effectively rinsed, and the impact is on the inner wall of the cover or container, so as to avoid Clean dead corners, improve cleaning effect, and ensure flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

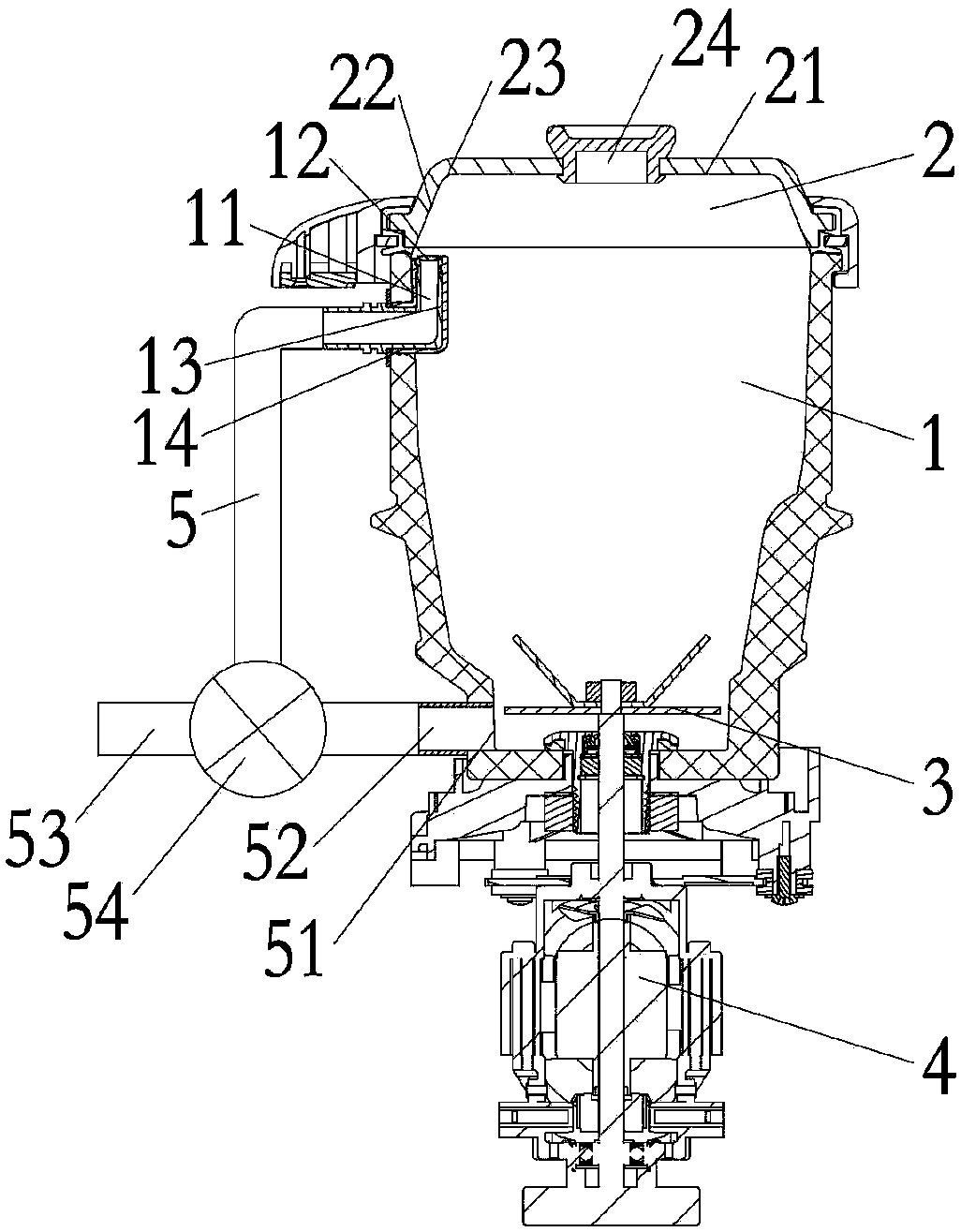

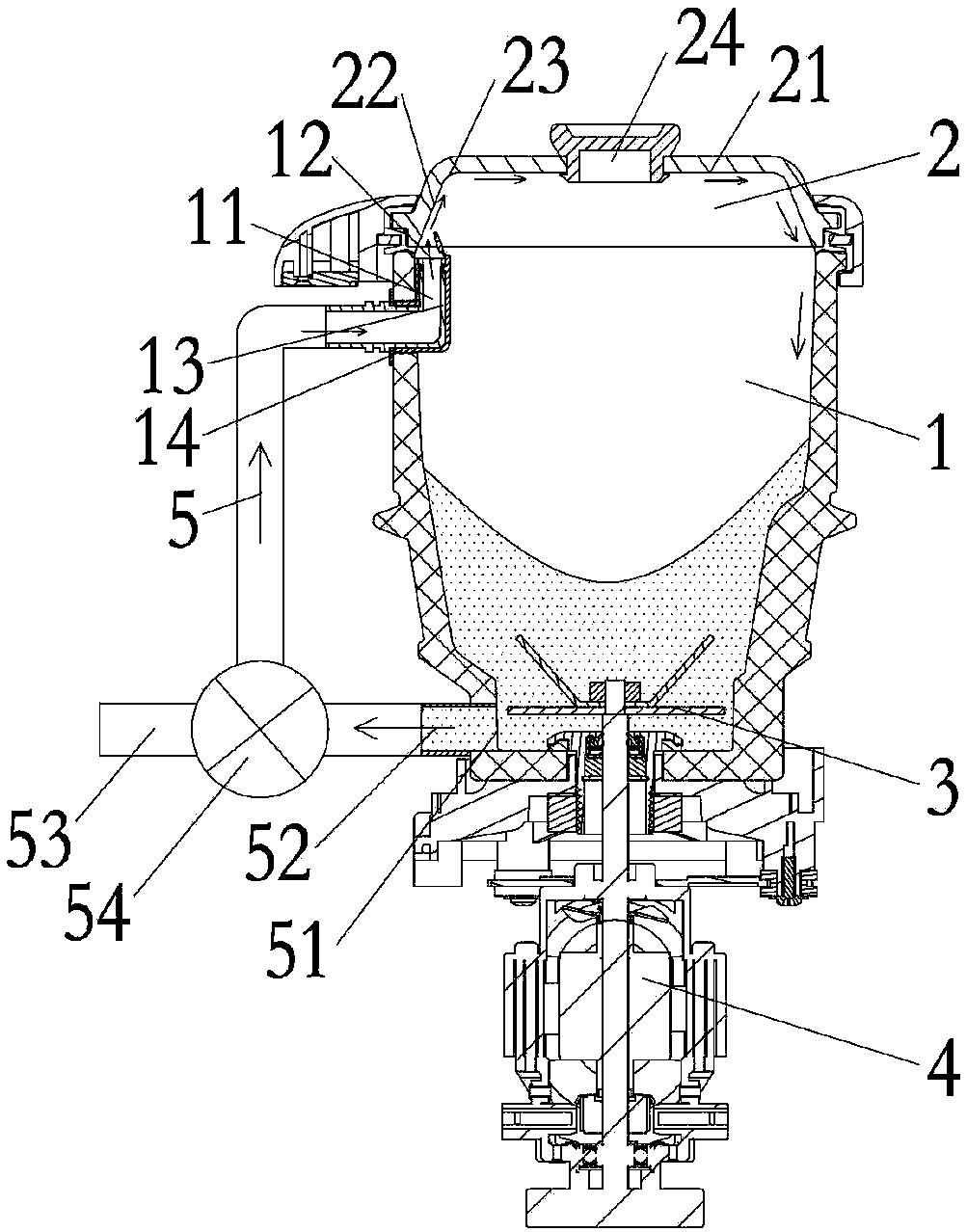

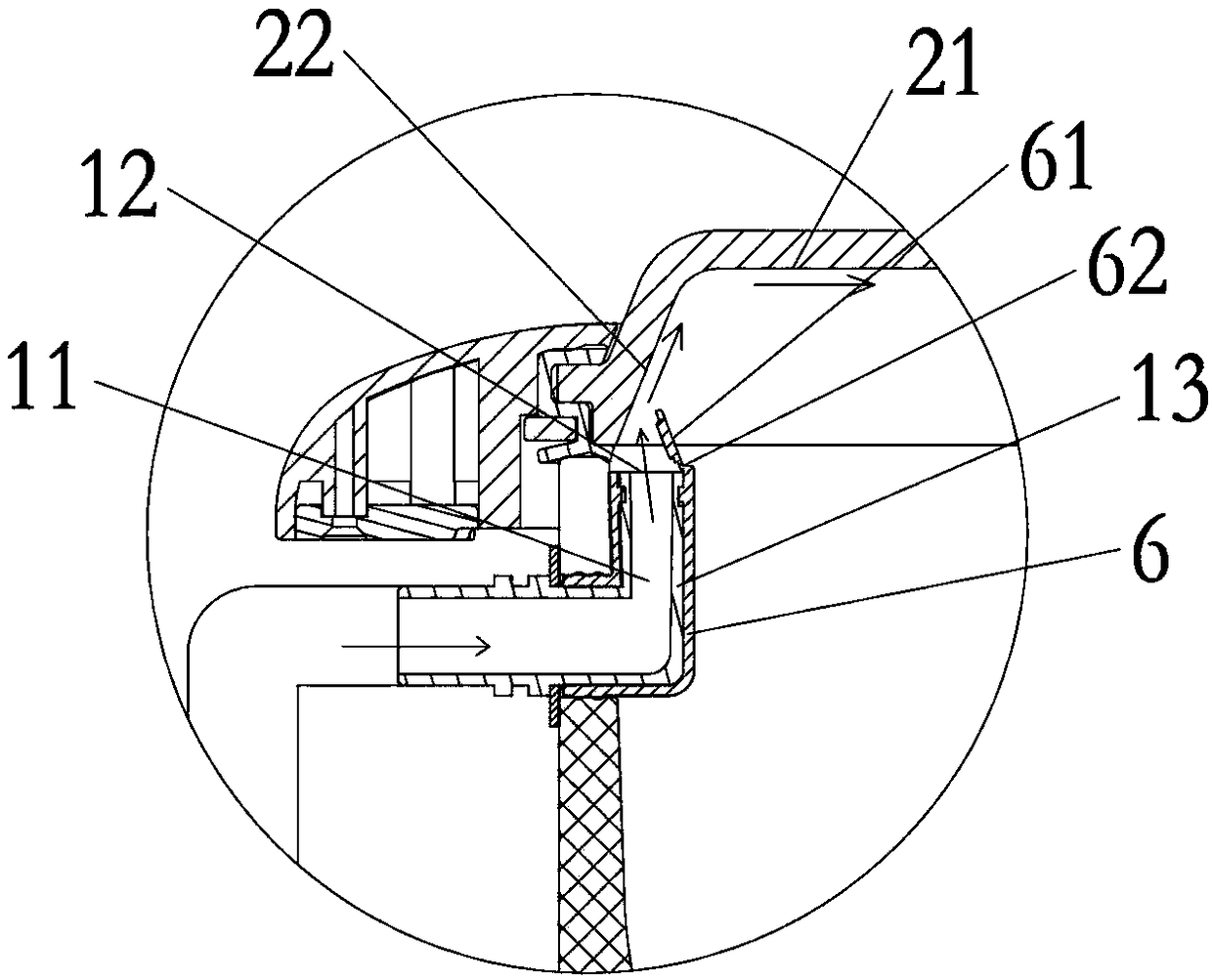

[0023] like Figure 1-Figure 5 As shown, a self-cleaning food processor includes a container 1, a cover body 2 and a crushing device 3. The cover body 2 is located above the container 1 and is sealed with the container 1. The crushing device 3 is arranged in the container 1 and driven by a motor 4. The sealing between the cover body 2 and the container 1 has multiple ways, and a sealing gasket can be arranged on the outer edge of the cover body 2, and the cover body 2 is placed on the container 1 to form a radial seal by compressing and fitting with its cup al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com