A fixture and a method for realizing the position tolerance of lifting lug parts by one clamping

A technology of parts and lifting lugs, which is applied in the field of fixtures and one-time clamping to realize the position tolerance of lifting lugs, which can solve the problems of inability to achieve mass production, high manufacturing costs, and high cost of five-axis machining centers, and achieve low cost, The effect of improving precision and avoiding secondary clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

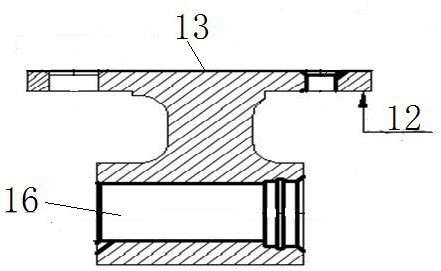

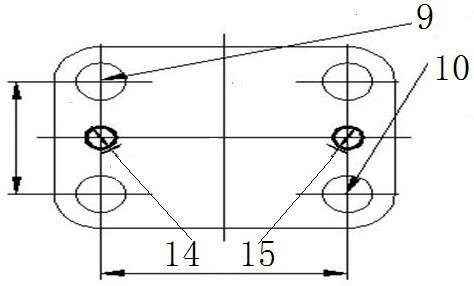

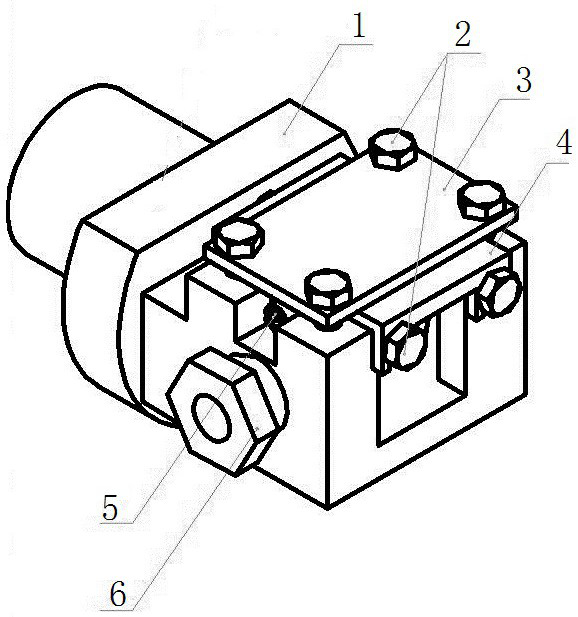

[0044] Such as image 3 , 4 As shown in , a fixture for realizing the position tolerance of lifting lug parts and related datum processing in one clamping, including:

[0045] The base 1 is used to place parts, and the base 1 includes a positioning surface 12 in contact with the parts;

[0046] Rhombus pin 9, in order to fix the position of parts;

[0047] Cylindrical pin 10, in order to fix the position of parts;

[0048] The front pressing plate 4 is used to compress the parts;

[0049] Rear pressing plate 7, in order to compress parts;

[0050] Side pressure plate 11, used to compress parts;

[0051] The top pressure plate 3 is used to compress the parts;

[0052] The threaded top ring 6 is used for tightening parts;

[0053] Press the bolt 2 so that the front pressure plate 4, the rear pressure plate 7, and the top pressure plate 3 fit the parts and are used to pre-tighten the parts;

[0054] The side pressure bolt 5 makes the side pressure plate 11 fit the parts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com