Chain saw for preventing accidents

A technology for preventing accidents and chainsaws, applied in the field of chainsaws, can solve the problems of unable to support chainsaws normally, lack of safety protection measures, and injury to workers' bodies, etc., to avoid accidental injuries, simple and reliable structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

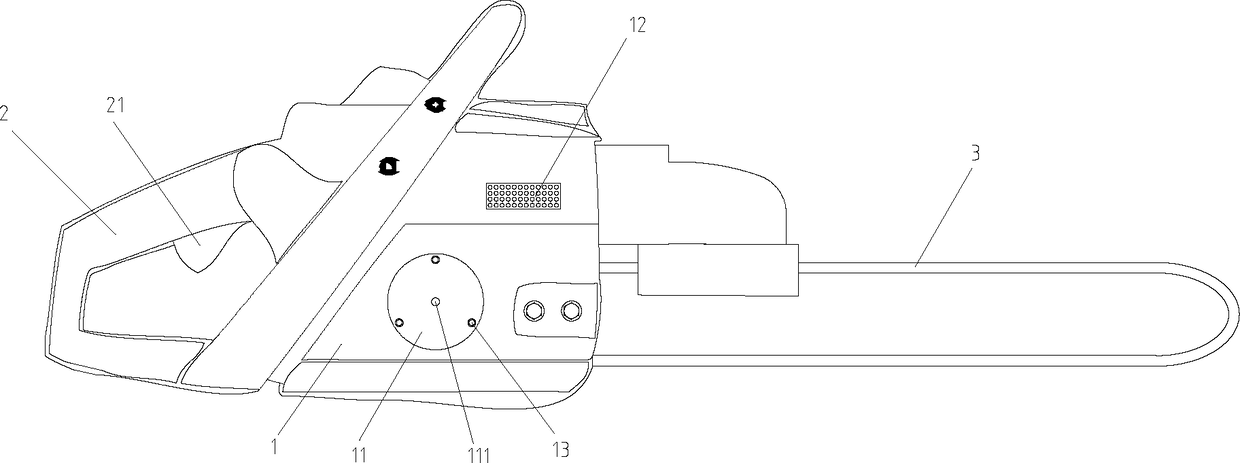

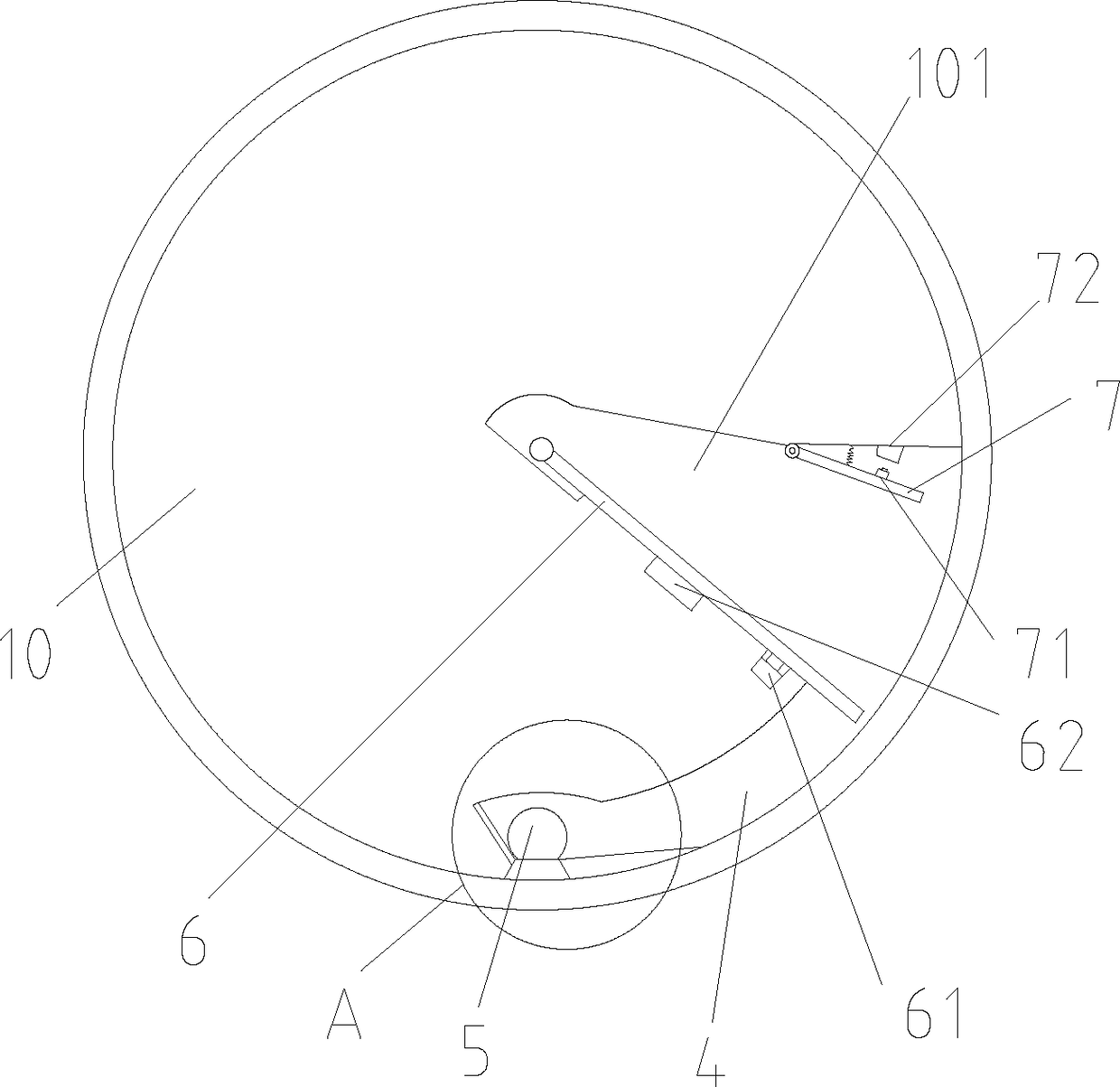

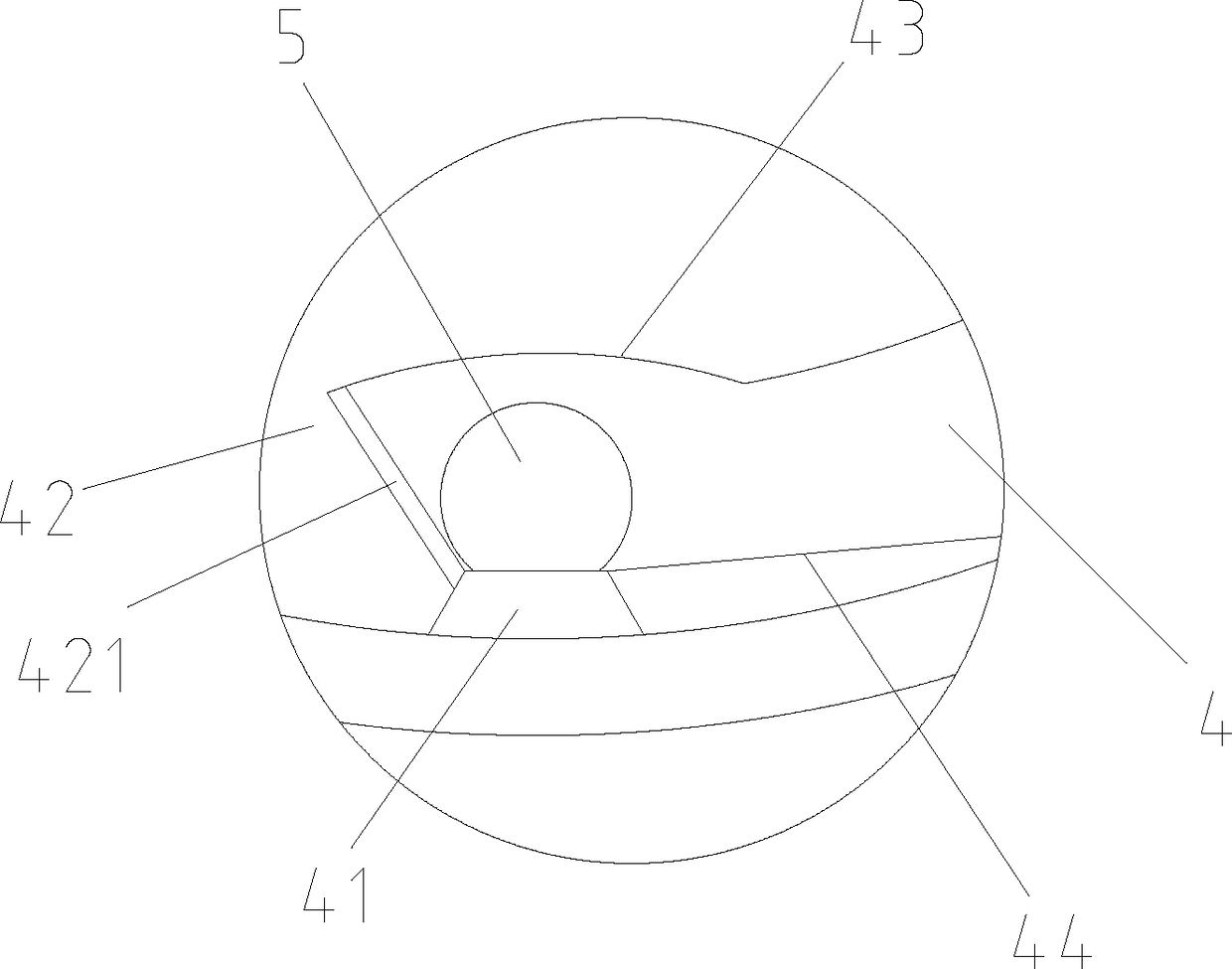

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 4 As shown, a chain saw for preventing accidents includes a main body 1 and a saw chain 3. A starter is arranged inside the main body 1, and the starter controls the operation of the chain saw. The main body 1 is provided with a handle 2. The grip part 2 is provided with a start switch 21; the side of the body 1 is provided with a cover plate 11, and the part of the body 1 covered by the cover plate 11 is provided with a working control part 10, and the working control part 10 is provided with an arc-shaped groove 4, and the arc-shaped groove 4 is connected with a pressure plate installation part 101, and the pressure plate installation part 101 is rotatably provided with a first pressure plate 6 and a second pressure plate 7; the lowest part of the arc-shaped groove 4 is located at On the vertical line passing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com