Prism type logistics transport equipment

A kind of technology of logistics handling and platform type, which is applied in the direction of transportation and packaging, multi-axis trolleys, trolleys, etc., which can solve the problems of threatening the safety of operators, inability to perform stable stacking, and low handling efficiency, so as to reduce the work flow and lighten the operation. Effects of load and reduced working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

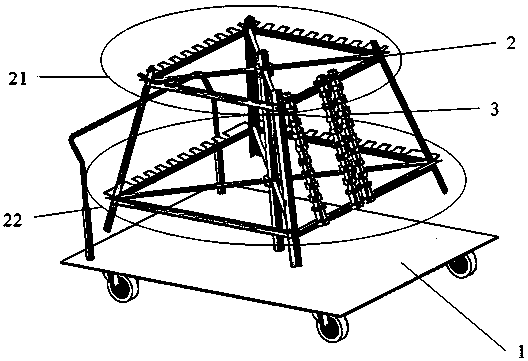

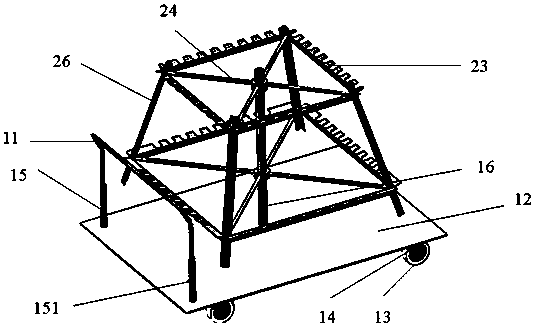

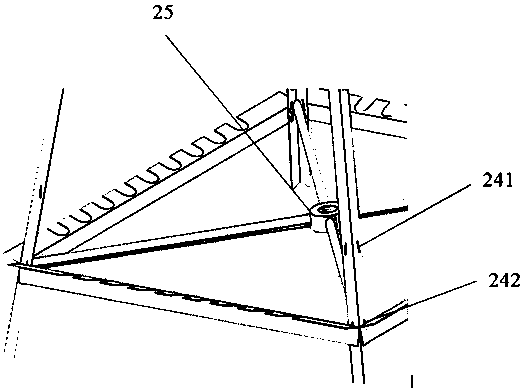

[0027] like Figure 1-4 As shown, embodiment 1 is a kind of edge platform logistics handling equipment, which is applied to storage and handling of automobile engine camshaft 3, including transport vehicle 1, and transport vehicle 1 is provided with edge platform frame structure 2 for placing camshaft 3; The truss frame structure 2 includes an upper structure 21 and a lower structure 22 , both of which are connected end to end by a clamping mechanism, and the clamping mechanism clamps the camshaft on the prism frame structure 2 . Due to the particularity of the camshaft structure of the automobile engine, in order to facilitate the placement of the camshaft and the fixation during transportation, a clamping mechanism is used to place the camshaft on the clamping mechanism of the upper and lower structures to realize the storage and installation of the camshaft. transportation.

[0028] Further, the transport vehicle 1 includes a handle 11, a load-bearing floor 12 and casters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com