Narrow-band type transfer conveyor

A conveyor and narrow-belt technology, which is applied in the field of narrow-belt transfer conveyors, can solve the problems that the number of transfer chain conveyors is not easy to change, the installation accuracy of linear bearings is high, and the radial force cannot be carried, etc., so as to achieve convenient and fast lifting , large synchronous gear bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

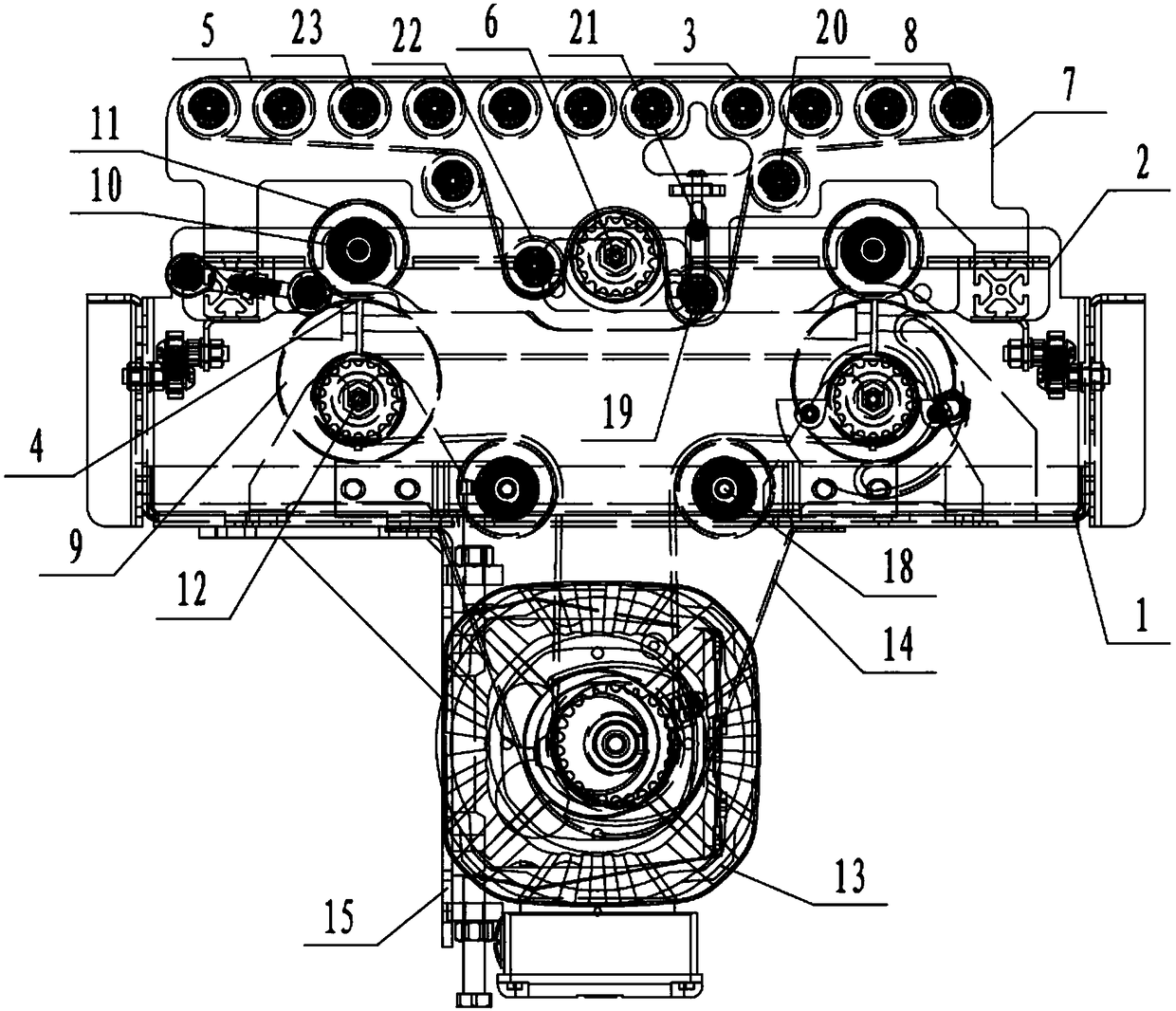

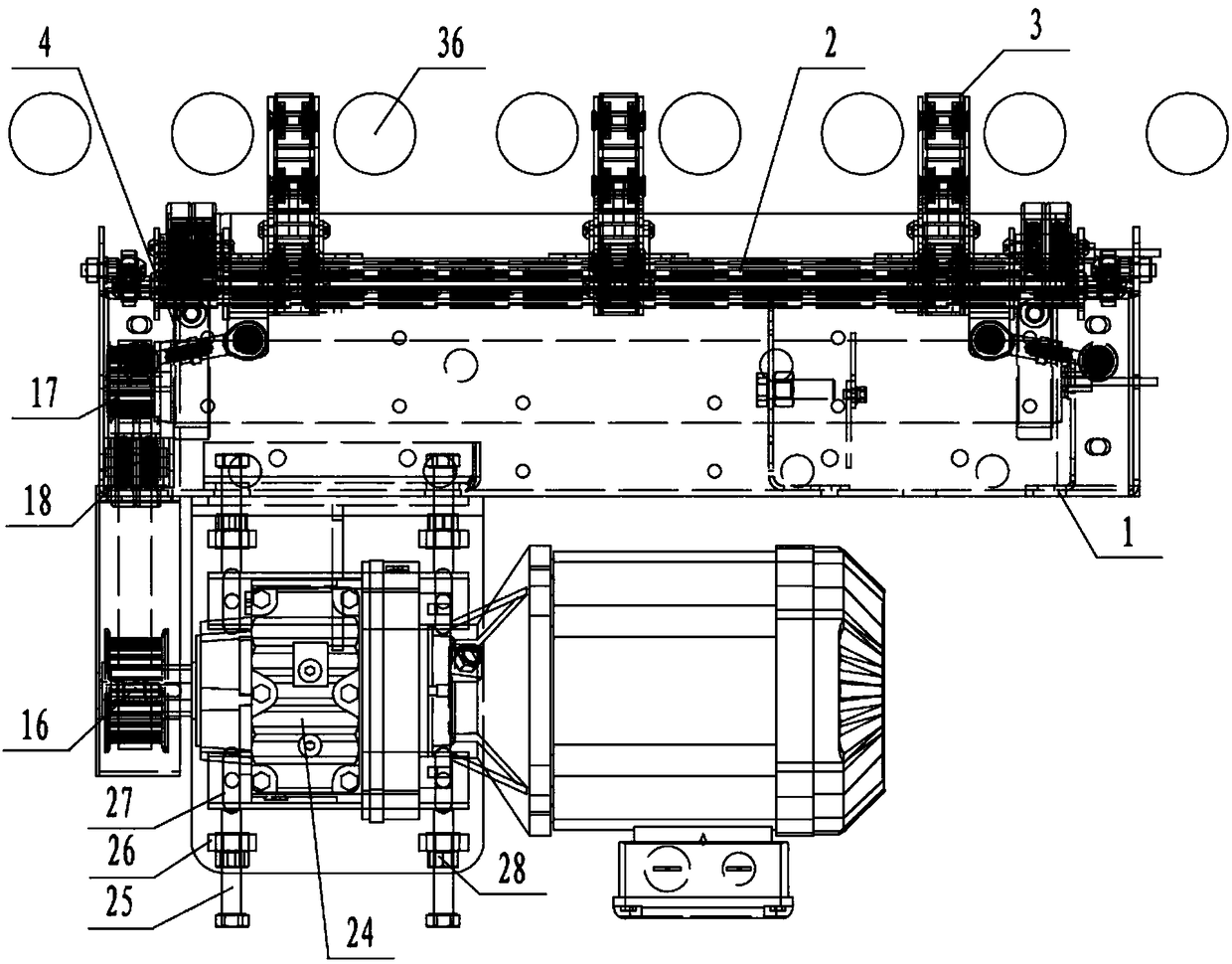

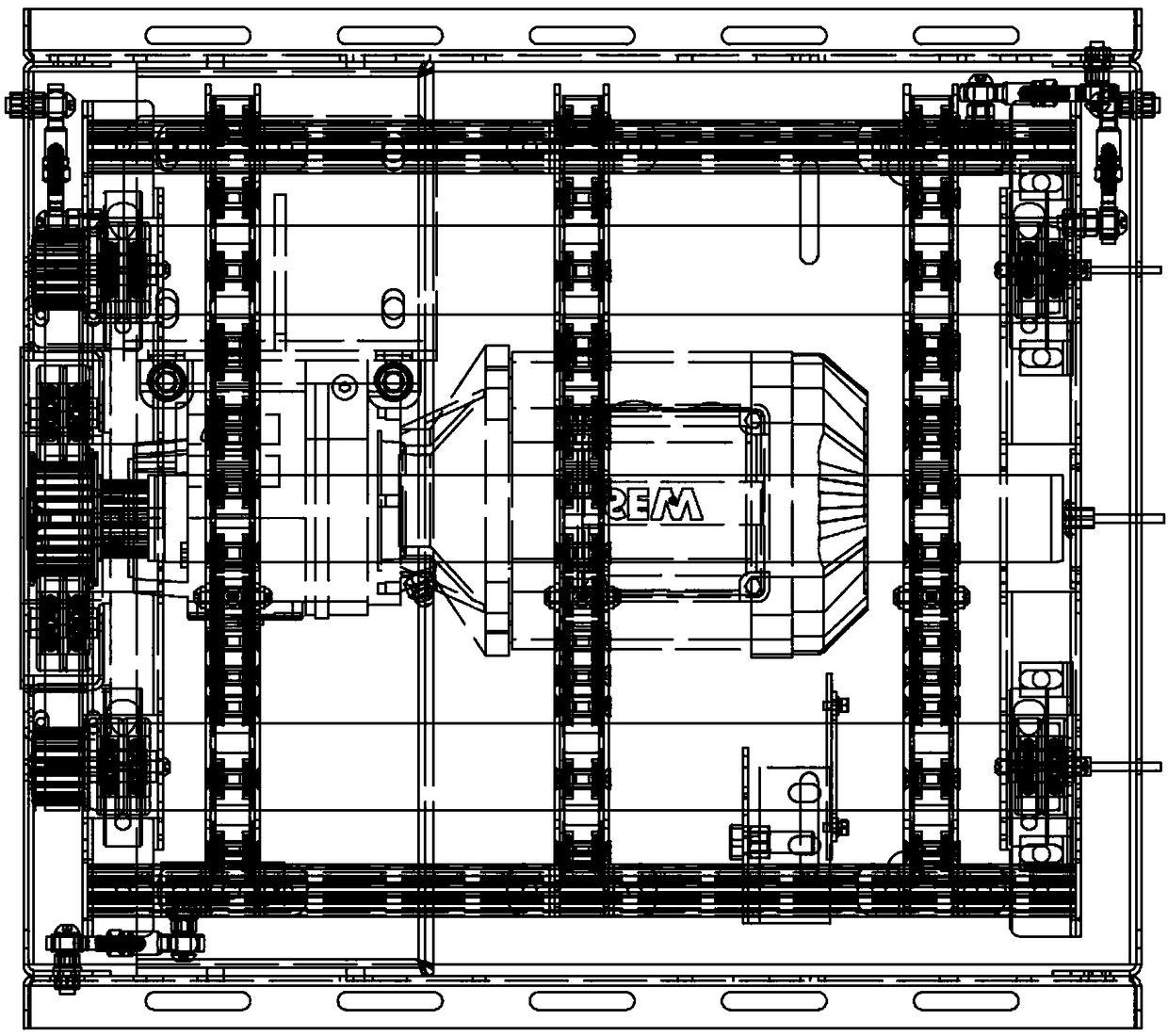

[0028] Embodiment 1: as Figure 1-4 As shown, a narrow-belt type transfer conveyor includes a frame 1, a lifting frame 2 and a transfer conveying narrow belt 3, and a plurality of transfer conveying narrow belts 3 are installed on the lifting frame 2 in parallel at intervals, and the lifting frame 2 passes through each A hinge mechanism on one side is connected to the frame 1 and a cam jacking mechanism 4 is provided at the bottom.

[0029] Preferably, the above-mentioned transfer conveying narrow belt 3 includes a driving narrow belt 5, an electric drum 6, a narrow belt frame 7 and two driven rollers 8, two driven rollers 8 are installed on the narrow belt frame 7, and the electric roller 6 is installed on the upper side of the lifting frame 2 The middle part is kept parallel to the two driven rollers 8, and the two driven rollers 8 are respectively located at both ends of the upper part of the narrow belt frame 7, and the driving narrow belt 5 is wound on the electric drum 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap