Winding device for multistrand metal wire

A winding device and metal wire technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of inability to move conveniently, the metal wires cannot be easily entangled together, and the placement of metal wires, etc. To achieve the effect of increasing the winding effect, reducing the space occupied, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

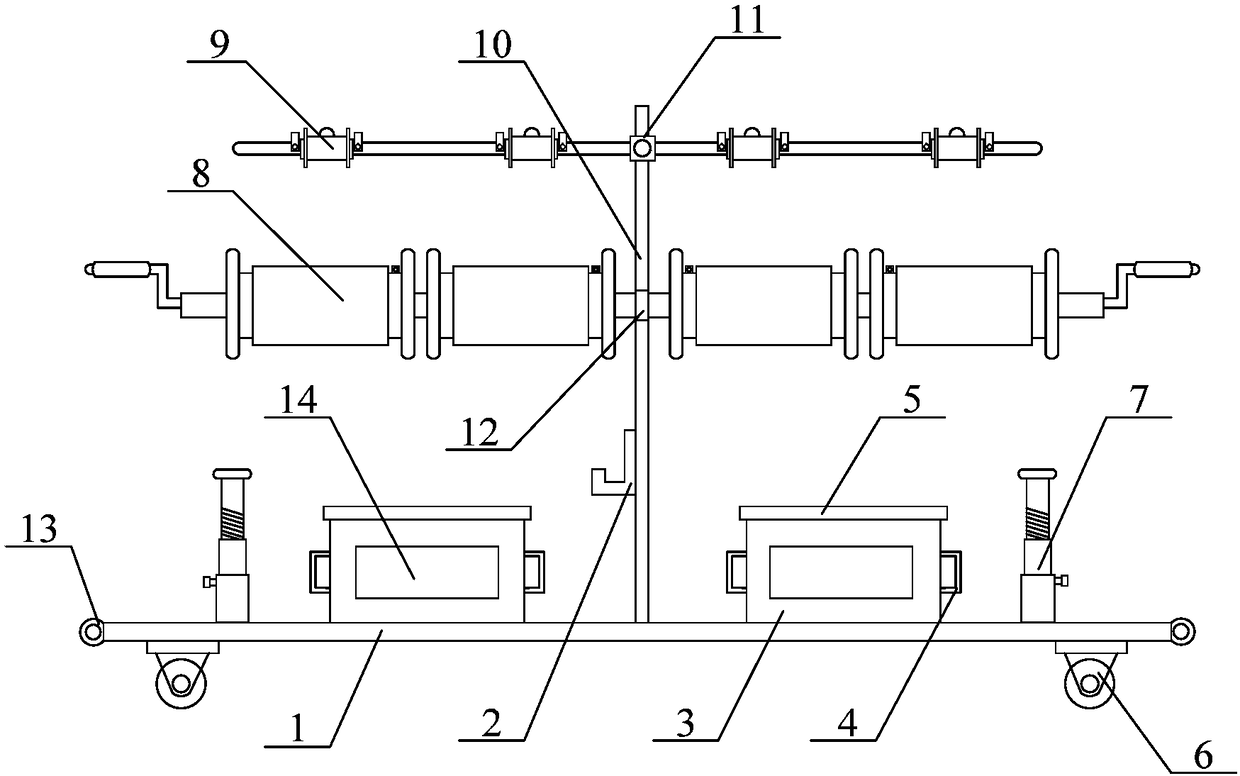

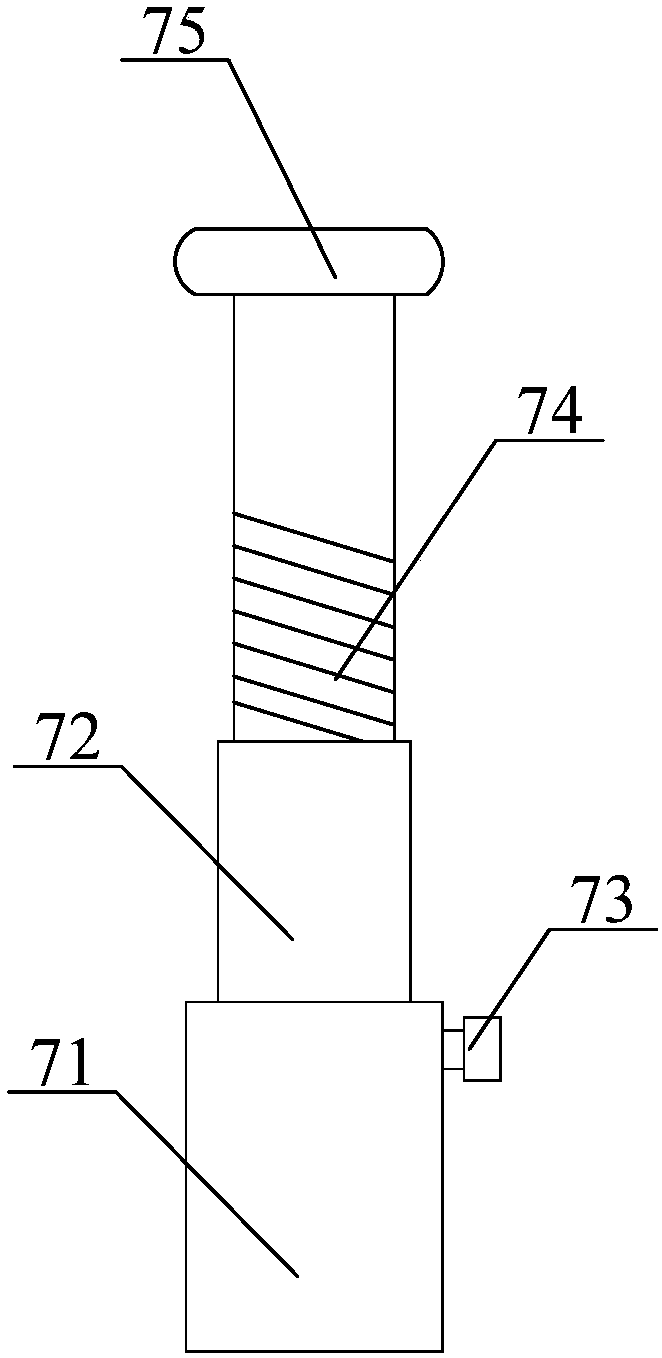

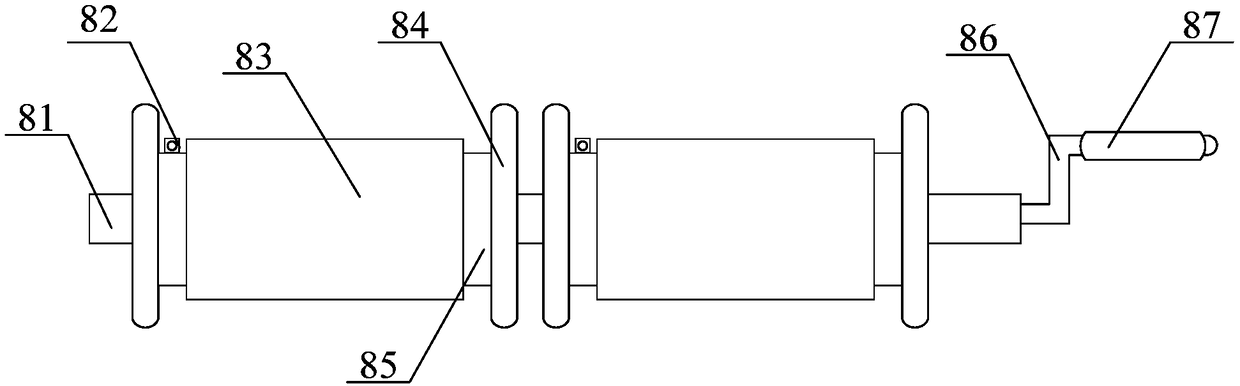

[0034] like Figure 1 to Figure 4 As shown, a multi-strand metal wire winding device according to the present invention includes a bottom plate 1, a hanging hook 2, a storage box 3, a handle 4, a protective cover 5, a universal wheel 6, and a telescopic adjustment for placing the metal wire. Rod structure 7, rotatable and detachable winding shaft structure 8, anti-falling metal wire placement rod structure 9, support rod 10, fixed block 11, bearing 12, pulling ring 13 and sticker 14, the hanging hook 2 is welded on the support rod 10 on the lower left side; the storage box 3 is respectively placed on the upper left side and the upper right side of the bottom plate 1; the handle 4 is screwed to the left middle position and the right middle position of the placement box 3 respectively; The protective cover 5 described above is fastened to the upper part of the storage box 3 respectively; the universal wheels 6 are respectively bolted to the four corners of the bottom of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com