Vanadium trioxide and preparation method thereof

A technology of vanadium trioxide and tetravalent vanadium, applied in vanadium oxide and other directions, can solve the problems of difficult operation conditions, high equipment requirements, unfavorable environmental protection and the like, and achieve the effects of easy implementation, simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

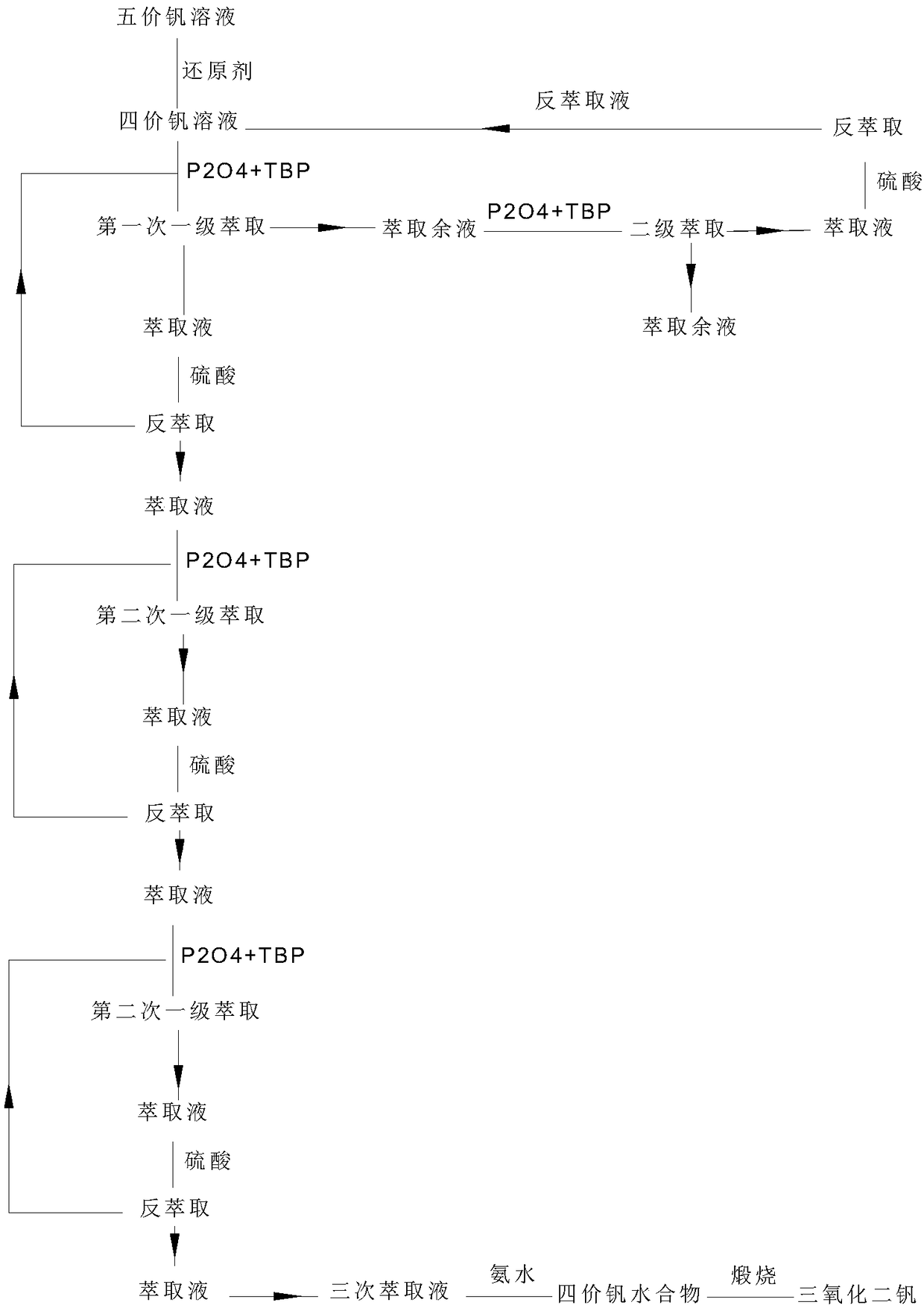

[0014] see figure 1 , a preparation method of vanadium trioxide, specifically, comprising the following steps:

[0015] S1, pretreatment;

[0016] The raw material for preparing vanadium trioxide provided in the embodiment of the present invention is a vanadium solution containing pentavalent vanadium, so it is necessary to react the vanadium solution containing pentavalent vanadium with a reducing agent to obtain a tetravalent vanadium solution. The reducing agent used is one or more of sodium sulfite, sulfur dioxide, iron powder or oxalic acid.

[0017] In the embodiment of the present invention, it is determined whether all the vanadium at the pentavalent position is reduced to tetravalent vanadium through the potentiometric titration method of detecting the discharge-treated solution. For specific detection methods, please refer to "Potentiometric Titration Analysis of Vanadium Battery Electrolyte; Tian Bo, Yan Chuanwei, etc.; Testing and Analysis; 2003, Volume 33, Issue...

Embodiment 1

[0040] A preparation method of vanadium trioxide, comprising the following steps:

[0041] S1, pretreatment;

[0042] Take 100mL of vanadium solution containing pentavalent vanadium, add a reducing agent under stirring conditions, and determine whether all low-priced vanadium is oxidized to tetravalent vanadium by detecting the potentiometric titration of the discharge-treated solution; the reducing agent is sodium sulfite.

[0043] S2, extraction;

[0044] With 500mL mixed extraction agent (kerosene containing 0.3mol / L P204 and 0.2mol / L TBP), join in the tetravalent vanadium solution (500mL), carry out the first primary extraction, extraction agent is compared with leachate (O / A) is 1:1, shake for 5 minutes, stand still to separate the liquid to obtain the extract (organic phase) and the raffinate.

[0045]The organic phase is back-extracted, and 1.5mol / L sulfuric acid is used for eluting, and 100mL1.5mol / L sulfuric acid is added to 500mL of the organic phase for the first...

Embodiment 2

[0057] This embodiment provides a preparation method of vanadium trioxide, which is basically the same as the preparation method in Example 1, except that the operating conditions are changed. Reducing agent is sulfur dioxide, and the concentration of two (2-ethylhexyl) phosphoric acid esters is 0.1mol / L in the mixed extractant, and the concentration of tributyl phosphate is 0.15mol / L, and the number of extractions is 4 times, and the comparison of extraction ( O / A) 2:1, the extraction time is 2 minutes, and the ratio (O / A) is 1:1 during the stripping process.

[0058] The pH of the tetravalent vanadium solution was adjusted to 7.5 with aqueous ammonia. During the adjustment process, ammonia water was added at a rate of 24 drops / minute, and the pH value of the tetravalent vanadium solution to which ammonia water was added was detected in real time. The concentration of tetravalent vanadium hydrate in the mixed solution is 150g / L. Wash 3 times with deionized water.

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com