Environmental-protection tin stripping liquid

A tin stripping and environment-friendly technology, applied in the field of environmental protection tin stripping liquid, can solve problems such as air pollution, water pollution, skin burns, etc., and achieve the effect of reducing waste gas pollution

Active Publication Date: 2018-08-21

昆山长优电子材料有限公司

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the use of nitric acid, it will volatilize to form acid mist and pollute the atmosphere; it will decompose to form nitrogen dioxide yellow smoke and nitric oxide mental poison; it will cause severe burns and scars when it touches the skin, which will pose hidden dangers to the personal safety of on-site opera

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

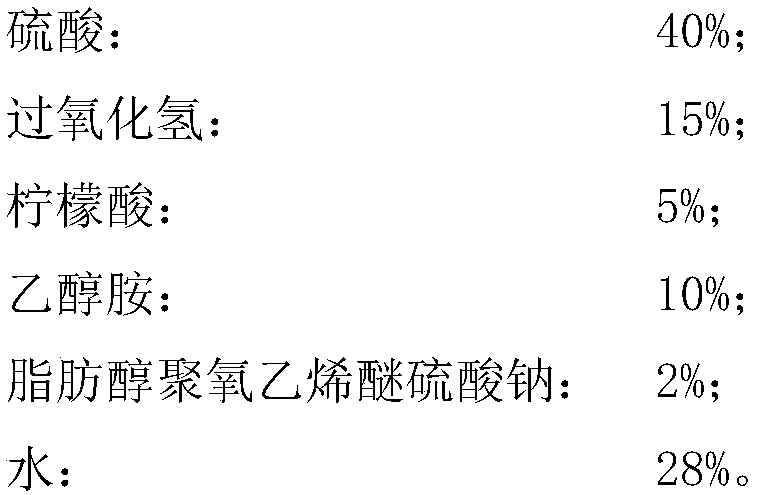

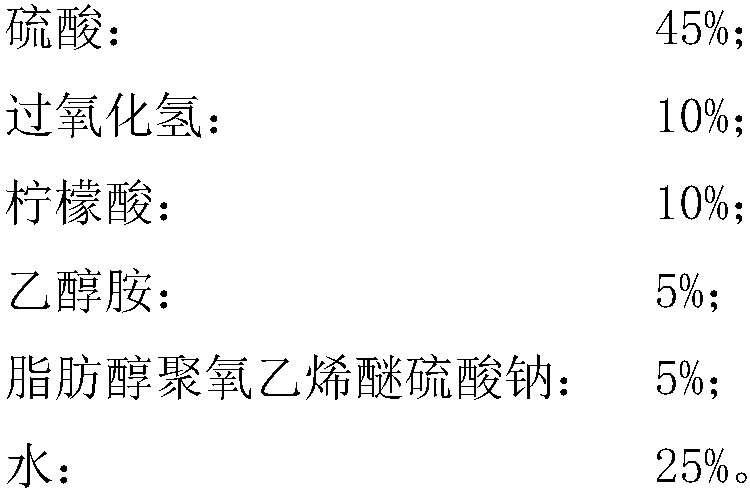

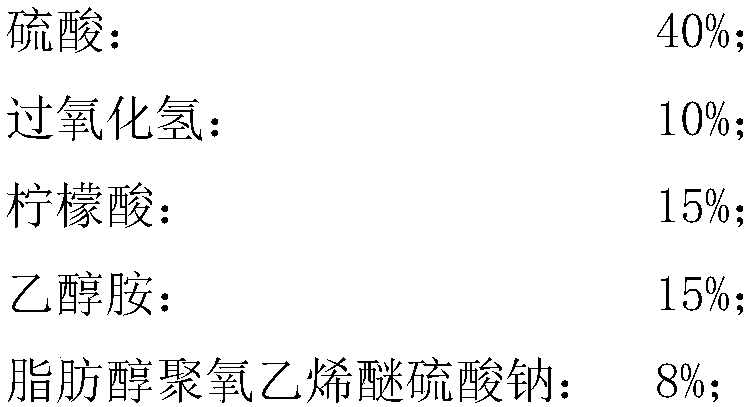

The invention discloses environmental-protection tin stripping liquid. The environmental-protection tin stripping liquid comprises the following components in percentage by weight: 5-50% of sulfuric acid, 1-20% of oxidizing agent, 1-20% of complexing agent, 1-20% of accelerating agent, 1-10% of surface active agent, and the balance of water. The environmental-protection tin stripping liquid can replace nitric acid for deplating and cleaning of electrotinning and chemical tin plating, reduces emission of nitrogen-contained waste water and emission of nitrogen monoxide and nitrogen dioxide poison gas due to use of nitric acid, and prevents potential safety hazards caused by use of nitric acid.

Description

Technical field [0001] The invention relates to an environmentally-friendly tin stripping liquid, which is used to replace nitric acid for cleaning and deplating tin electroplating and chemical tin plating, and belongs to the field of metal deplating. Background technique [0002] Since the patent of tin electroplating was issued in 1843, tin plating technology has been continuously improved with the development of science and technology for more than 100 years. At first, it was mainly used as a protective coating for steel metal. However, with the rise of the third industrial revolution in the middle of the 20th century, the development of the electronic industry is advancing by leaps and bounds. Due to its excellent solderability, tin (and its alloy) coatings are gradually applied to semiconductor devices, connectors, resistors and capacitors and other electronic industries. As a welding coating. [0003] Nowadays, the industrialization of tin electroplating has been very mature...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/30

CPCC23F1/30

Inventor 冯献超冯泽宪唐瑞泽

Owner 昆山长优电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com