Air-fuel ratio measurement system comprising optical sensor

A measurement system and optical sensor technology, applied in the field of measurement systems, can solve problems such as difficulty in optimizing system performance, and achieve the effect of small impact and optimized air-fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The components constituting the air-fuel ratio measuring system including the optical sensor of the present invention can be used as a whole or separately as needed. Also, some components may be omitted in use depending on the usage form.

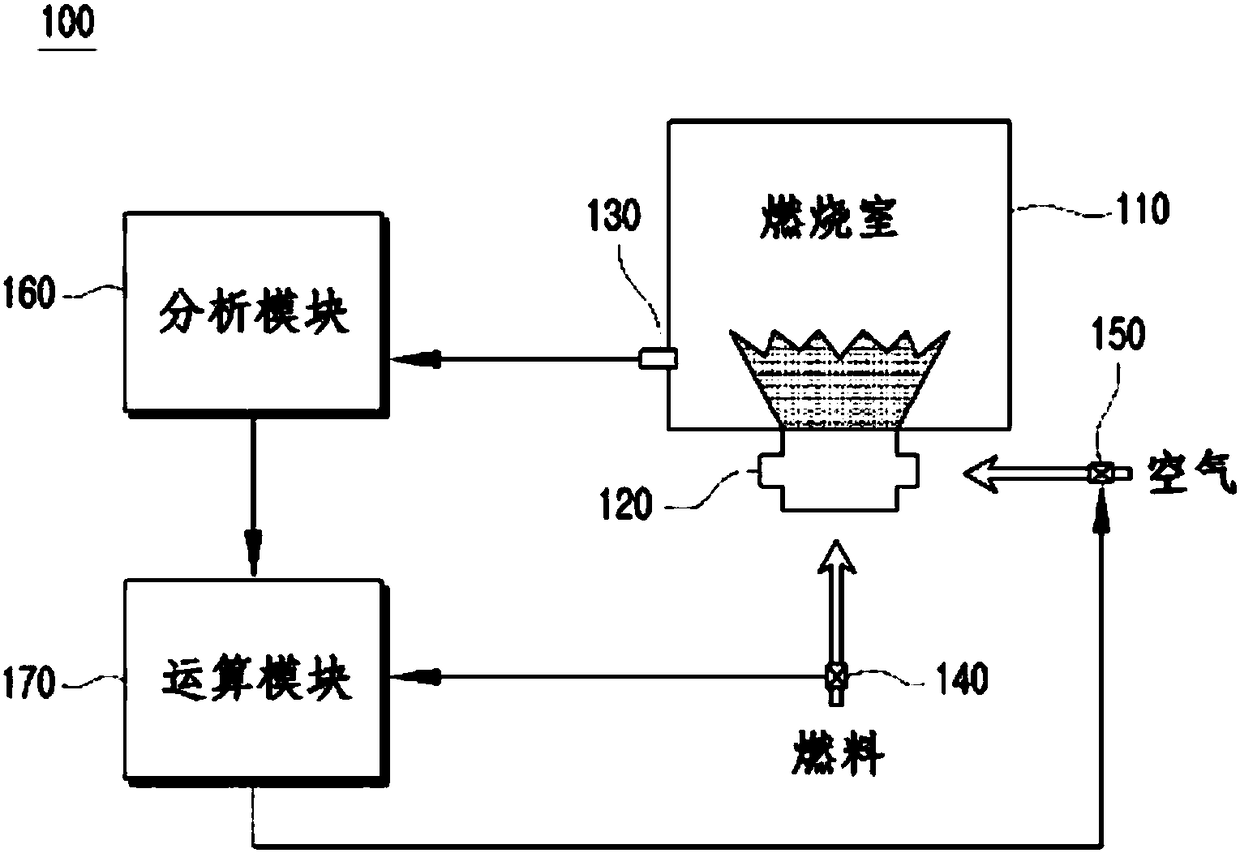

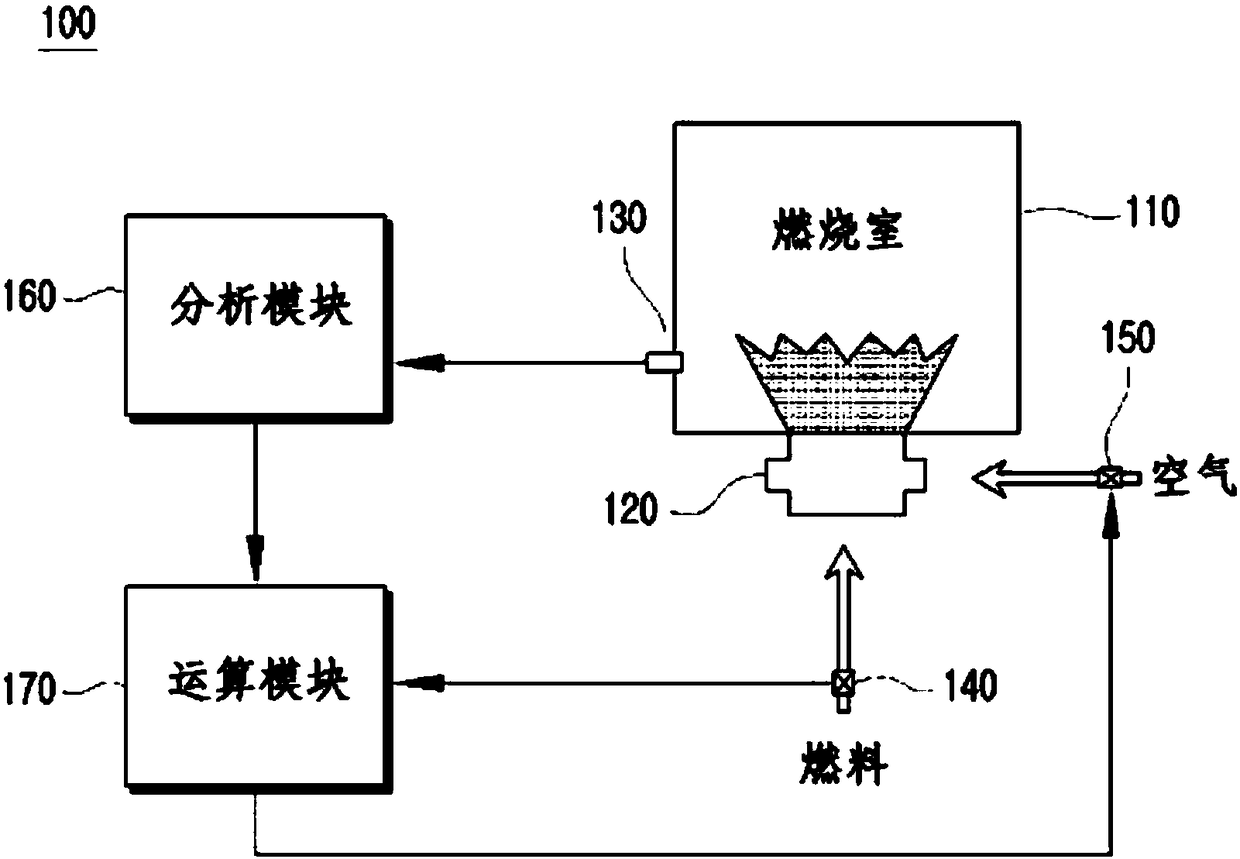

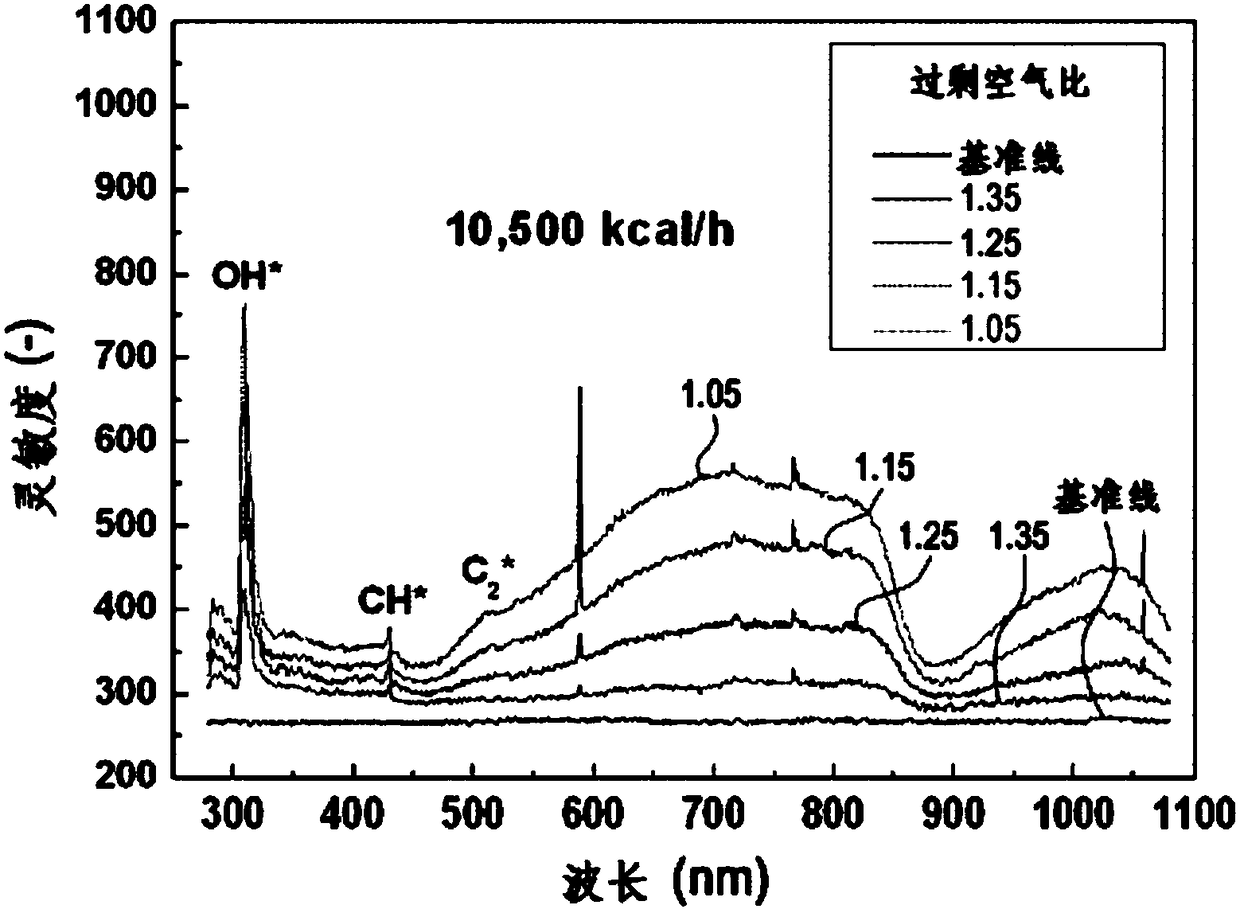

[0034] refer to Figure 1 to Figure 8 A preferred embodiment of the air-fuel ratio measurement system 100 including the optical sensor of the present invention is described. In this process, in order to make the description more clear and convenient, the thickness of the lines or the size of the components shown in the drawings may be exaggerated. In addition, terms described later are terms defined in consideration of functions in the present invention, and may be changed according to user's or operator's intention or custom. Therefore, the definitions of these terms should be described based on the entire content of this specification.

[0035] Below, refer to Figure 1 to Figure 2 An air-fuel ratio measurement system 100 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com