Control system applied to dual-fuel accurate combustion of double-hearth lime kiln

A double-chamber lime kiln and control system technology, applied in the field of lime calcination, can solve the problems of restricting the promotion of double-chamber kilns, inability to use double-chamber kilns, and large changes in gas calorific value and pressure, reducing actions and interventions, liberating labor, The effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

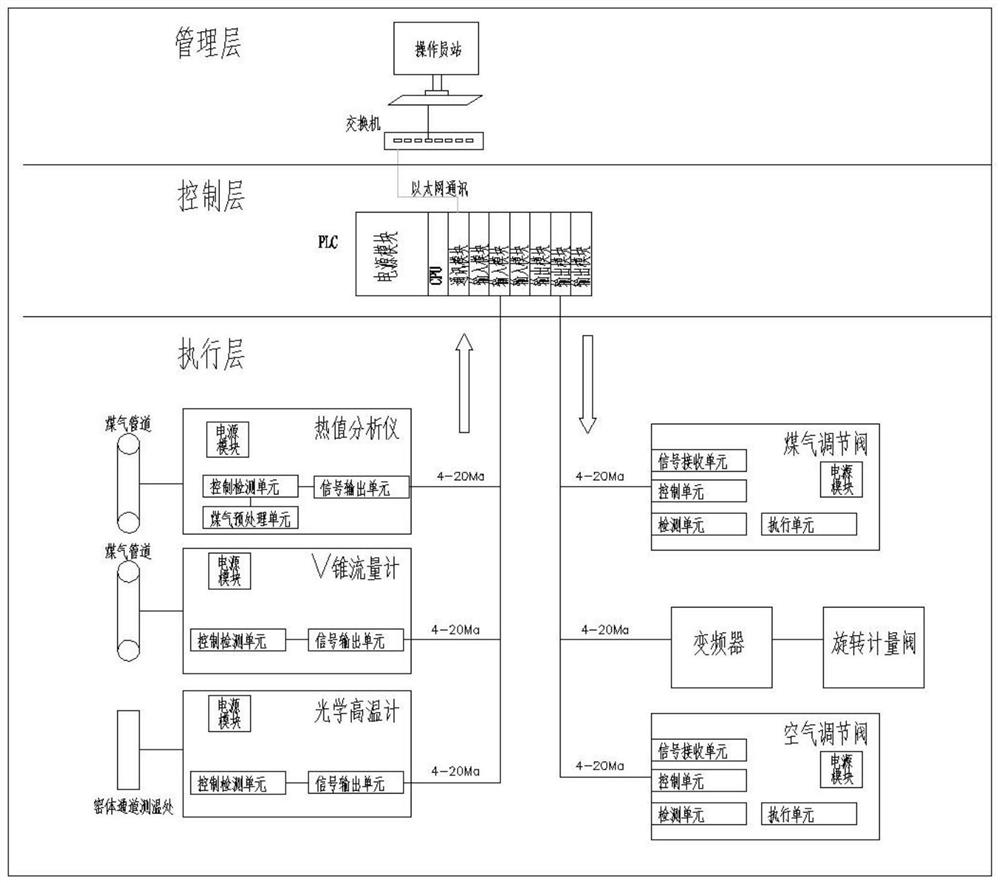

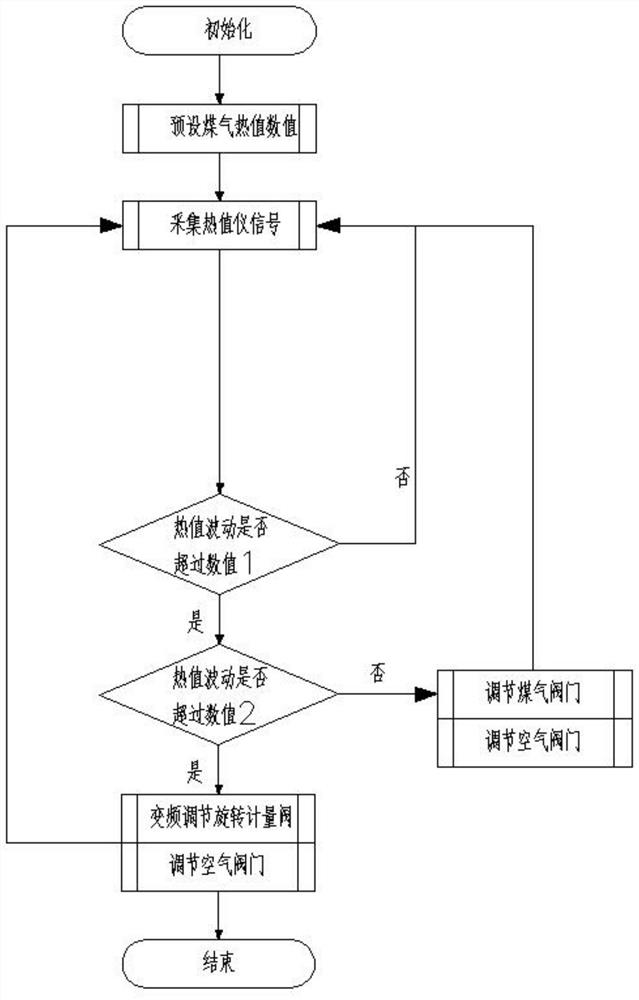

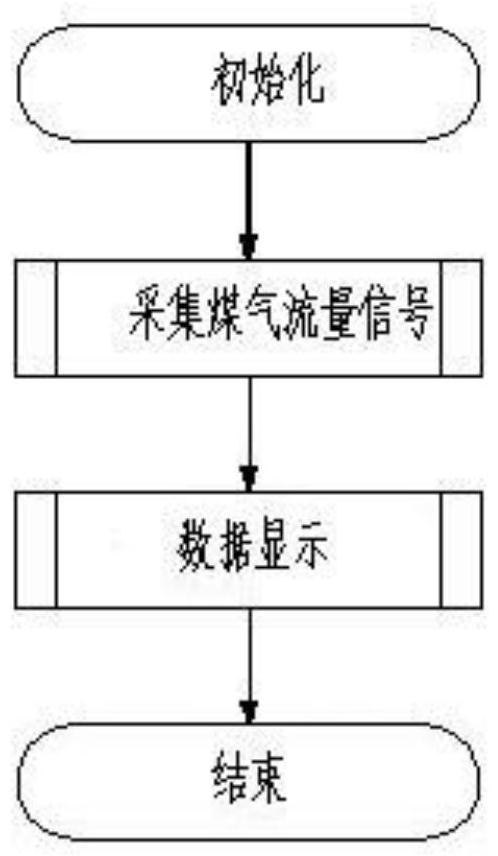

[0060] This application discloses a control system for dual-fuel precise combustion in a double-chamber lime kiln. According to changes in gas calorific value and flow rate, through external detection equipment and a mathematical model set in the program, real-time adjustment of gas and coal powder The dosage can achieve real-time optimization of the air-fuel ratio, ensure full combustion of fuel, and ensure that the heat required for lime calcination remains unchanged. Thereby reducing the shutdown rate of the double-chamber lime kiln, reducing human actions and interventions, and liberating the labor force. It can automatically adjust the supply of gas and pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com