Priming valve

A filling valve and valve seat technology, which is applied in the field of hydraulic oil filling and draining control valves, can solve the problems of inability to meet the requirements of the installation space of intelligent electro-hydraulic actuators, large volume, etc., and achieves compact structure, small volume, The effect that meets the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

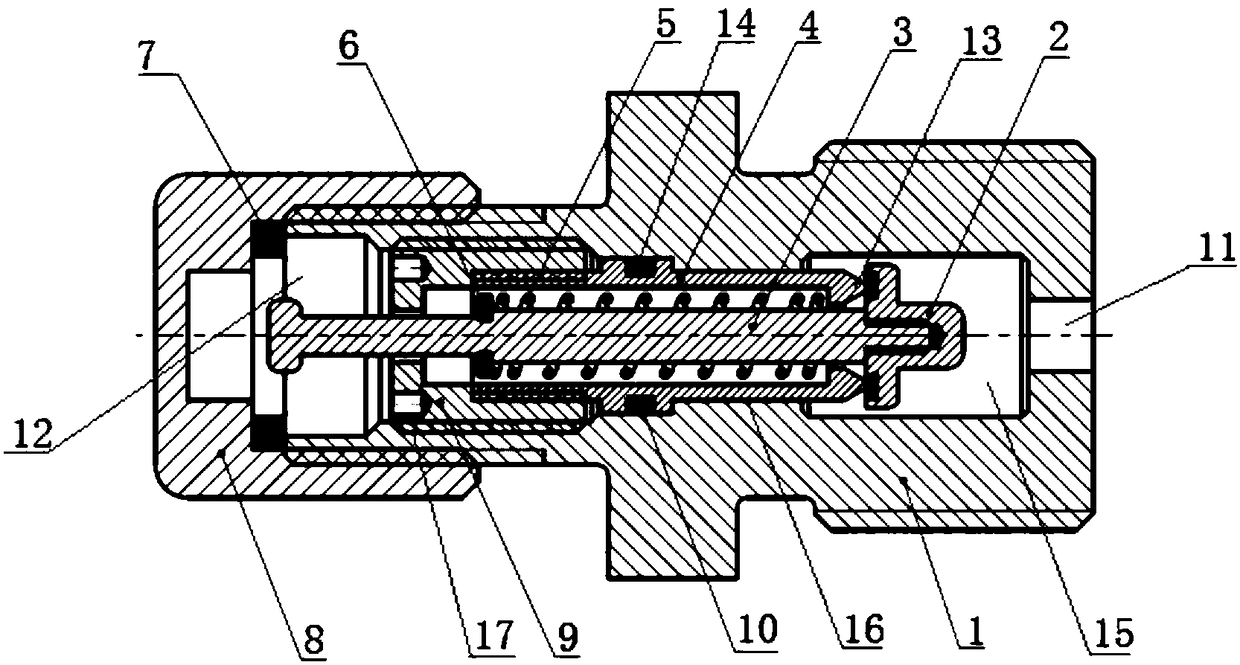

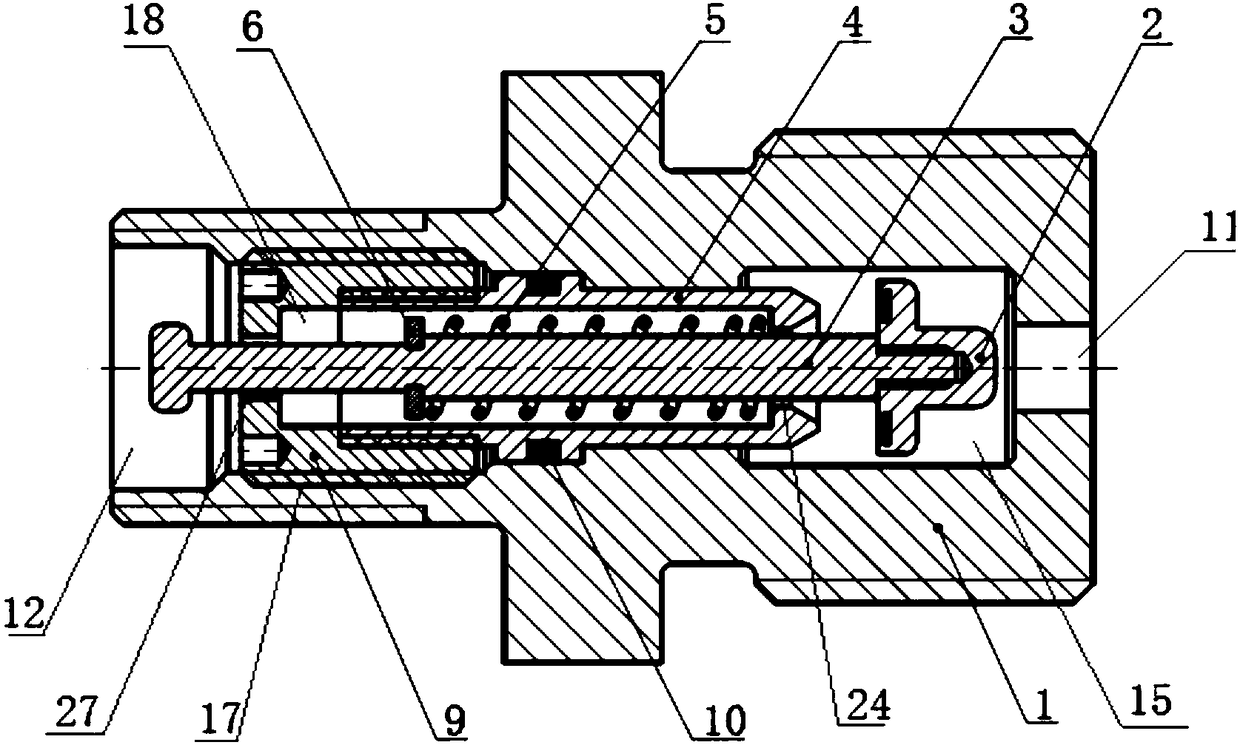

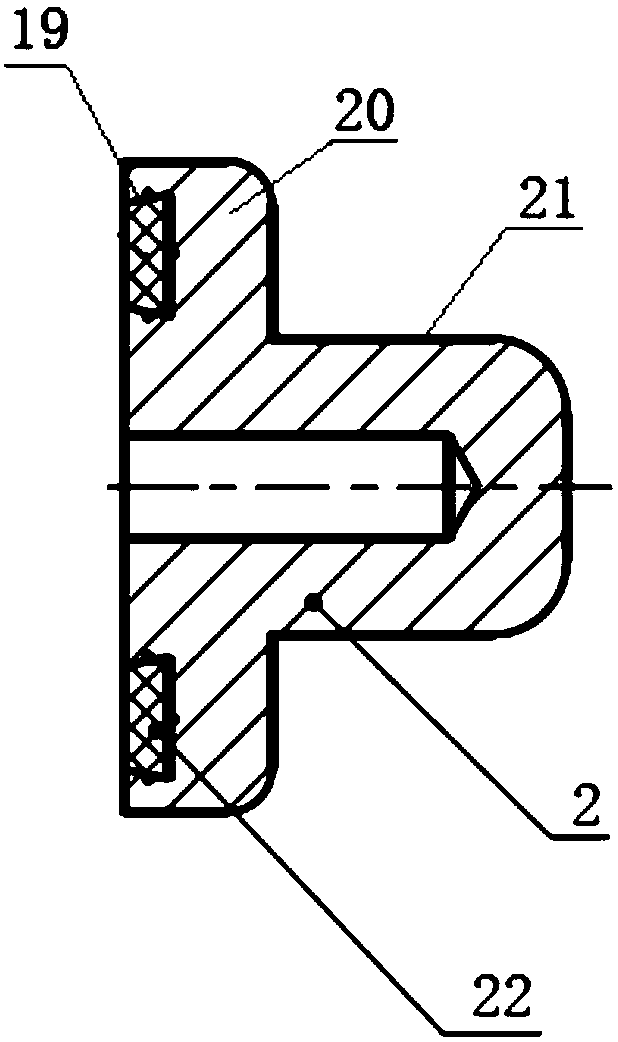

[0025] Such as Figure 1 to Figure 5 As shown, the present invention discloses a refueling valve, which includes a valve body 1, and the two ends of the valve body 1 are respectively provided with an oil inlet 12 and an oil outlet 11, wherein the oil inlet 12 is larger and the oil outlet 11 is larger. Small, the oil inlet 12 and the oil outlet 11 are coaxially arranged; the valve body 1 is provided with an installation cavity coaxial with the oil inlet 12 and the oil outlet 11 in the axial direction and connected, and the installation cavity is provided with The valve seat 4, the valve seat 4 is used to install the push rod 3, and cooperates with the valve core 2 to realize the sealing function.

[0026] The installation cavity is a circular cavity with step-by-step diameter reduction, including a fixed cavity 17, a sealed cavity 16 and a diversion cavity 15 arranged coaxially in sequence, such as figure 1 As shown, the fixed chamber 17 is connected to the oil inlet 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com