Laboratory ventilation system

A ventilation system and laboratory technology, applied in the field of laboratory equipment, can solve the problems of large indoor positive pressure, large indoor negative pressure, unfavorable discharge of toxic and harmful substances, etc., and achieve the effect of ensuring safety and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

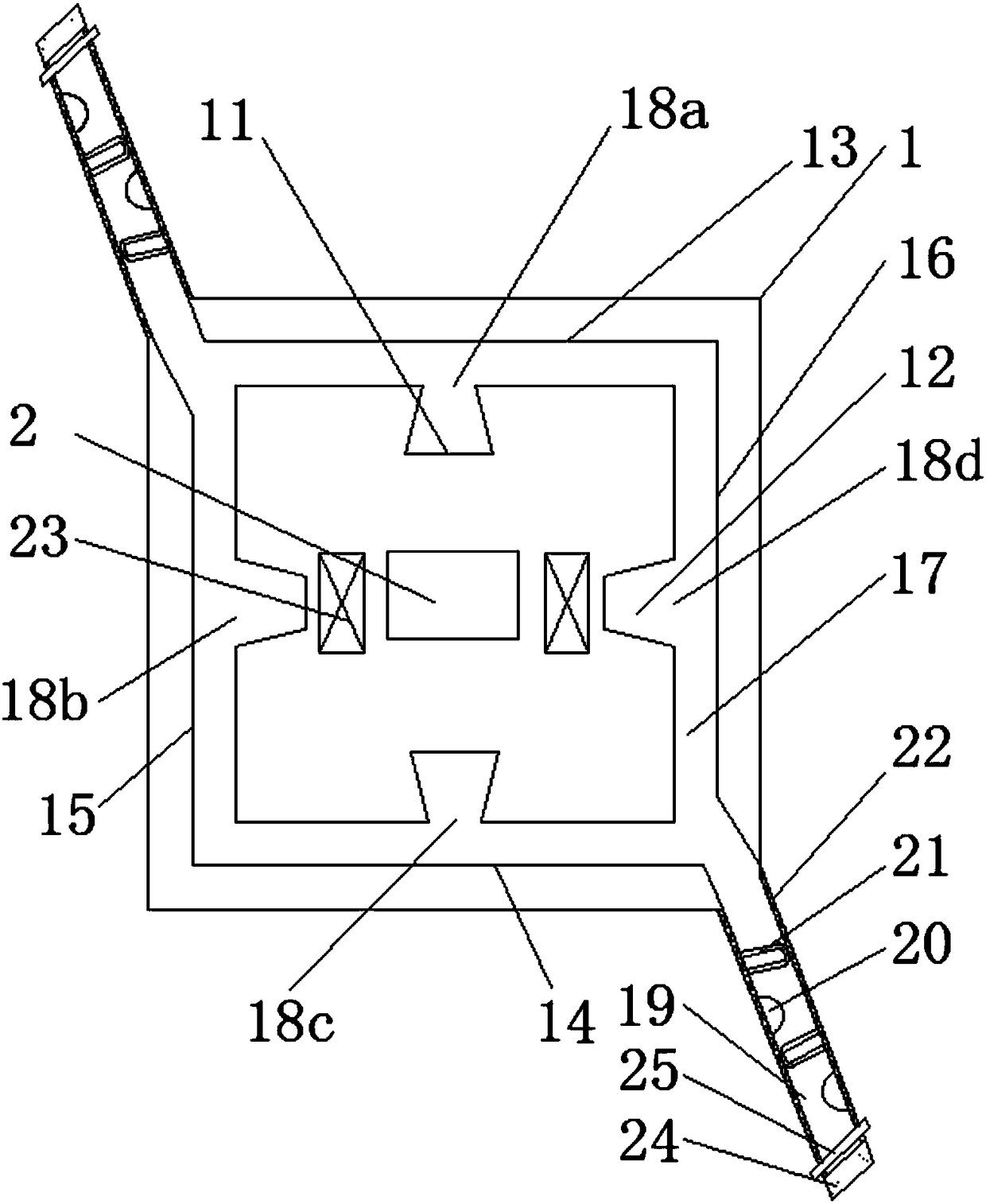

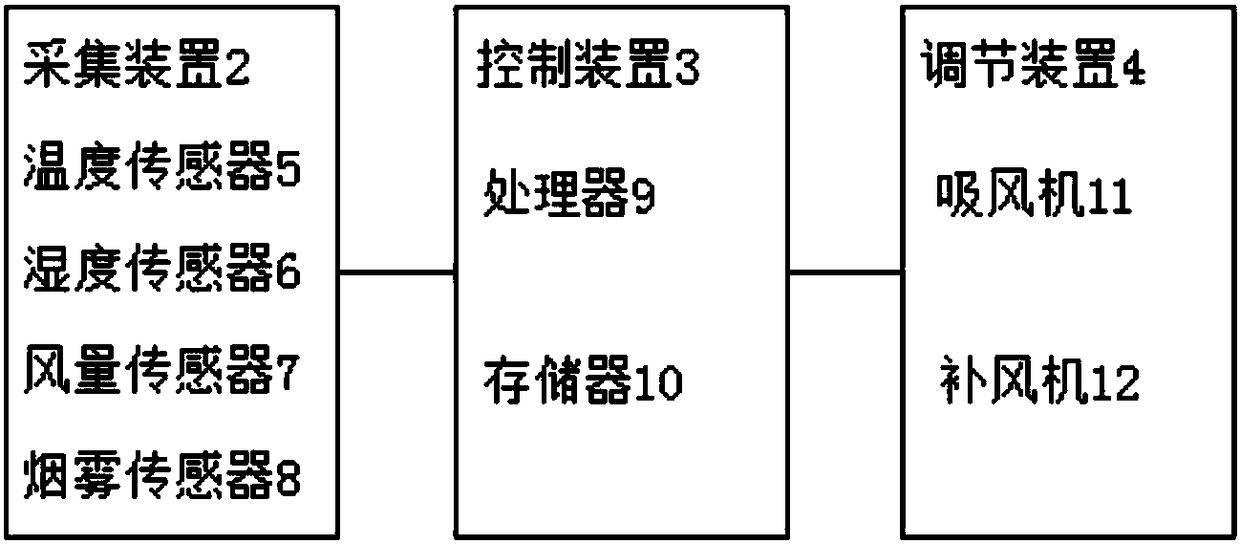

[0019] Refer to attached Figure 1-2 As shown, a laboratory ventilation system includes a laboratory 1, a collection device 2, a control device 3 and an adjustment device 4, the collection device 2 and the adjustment device 4 are all connected to the control device 3, and the collection device 2 Located at the center of the laboratory 1, the collection device 2 includes a temperature sensor 5, a humidity sensor 6, an air flow sensor 7 and a smoke sensor 8, the control device 3 includes a processor 9 and a memory 10, and the adjustment The device 4 includes two suction fans 11 and two supplementary fans 12, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com