Grinding device for bamboo wiredrawing knife with knife grinder

A knife sharpening device and a knife sharpening machine technology, which are applied in the direction of grinding machine tool parts, grinding racks, manufacturing tools, etc., can solve the problems of affecting the grinding toughness precision, low grinding toughness precision, and large motor vibration, etc., to achieve improved Grinding toughness precision, reducing vibration, improving the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

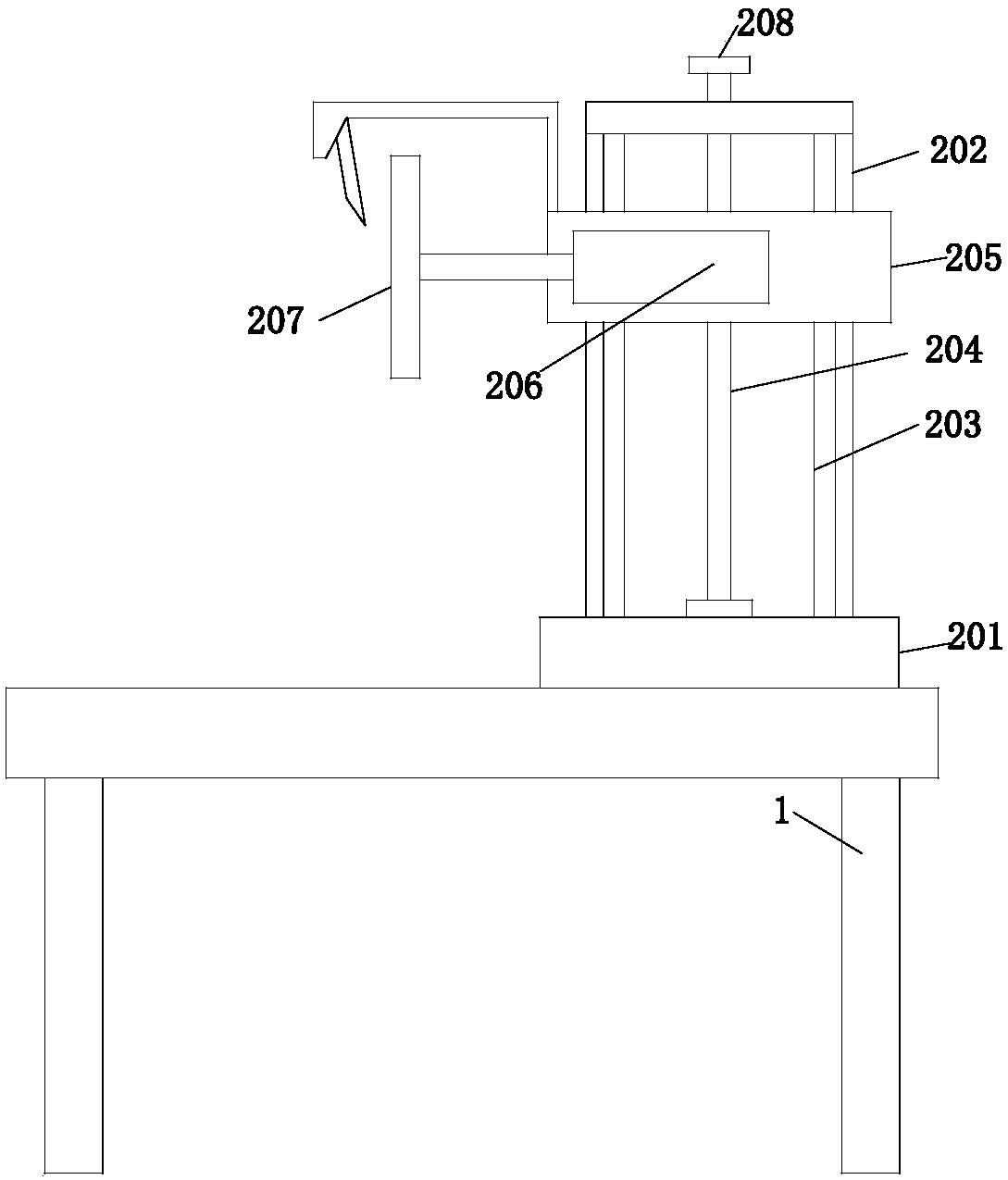

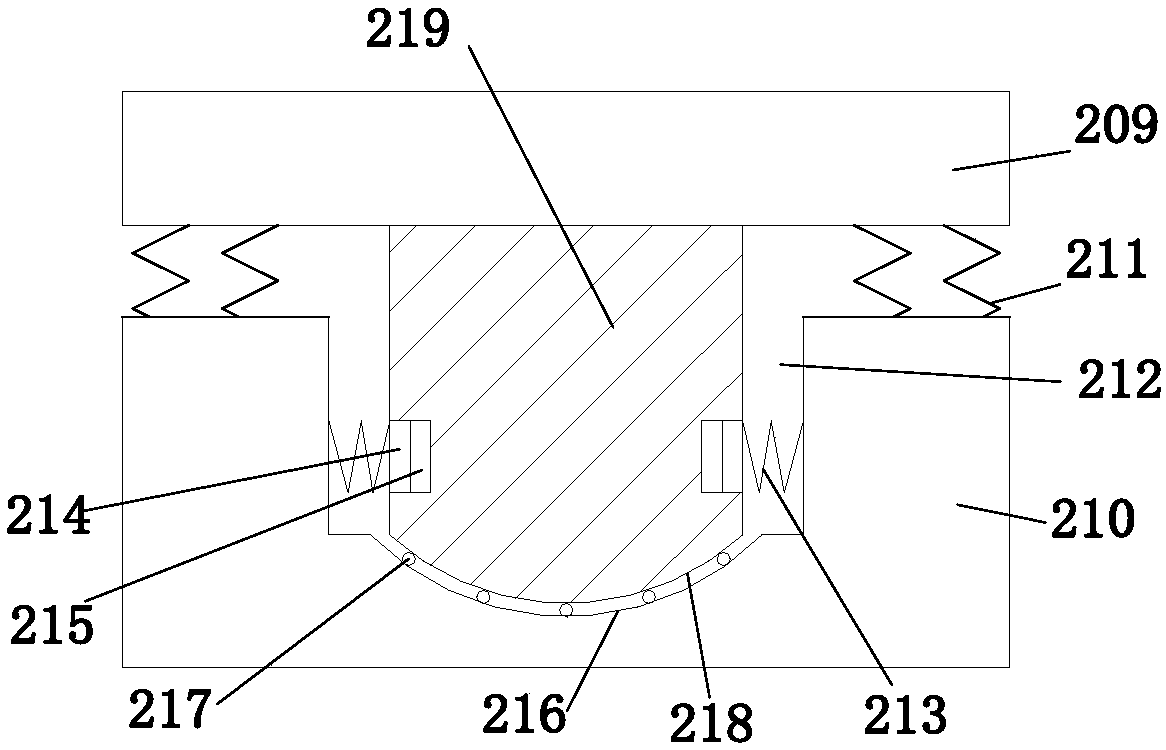

[0013] Example. A sharpening device of a sharpening machine for bamboo wire drawing knives is constituted as follows figure 1 and figure 2 As shown, including the frame 1, the top of the frame 1 is provided with a shock absorber 201, the top of the shock absorber 201 is provided with a sharpening bracket 202 arranged vertically, and the sharpening bracket 202 is provided with two vertical guide rails arranged in parallel 203, a screw mandrel 204 vertically arranged is provided between the two vertical guide rails 203, a nut slide seat is provided on the screw mandrel 204, a lift seat 205 is provided on the side of the nut slide seat, and a vertical lift seat 205 is provided on the inside surface of the lift seat 205. The guide holes of the guide rails 203 cooperate with each other, the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com