Precise grinding device for inner surface of steel tube

A technology of precision grinding and steel pipe, applied in the direction of grinding machine parts, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. It can reduce the influence of machining accuracy, stabilize machining quality, and adjust quickly and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

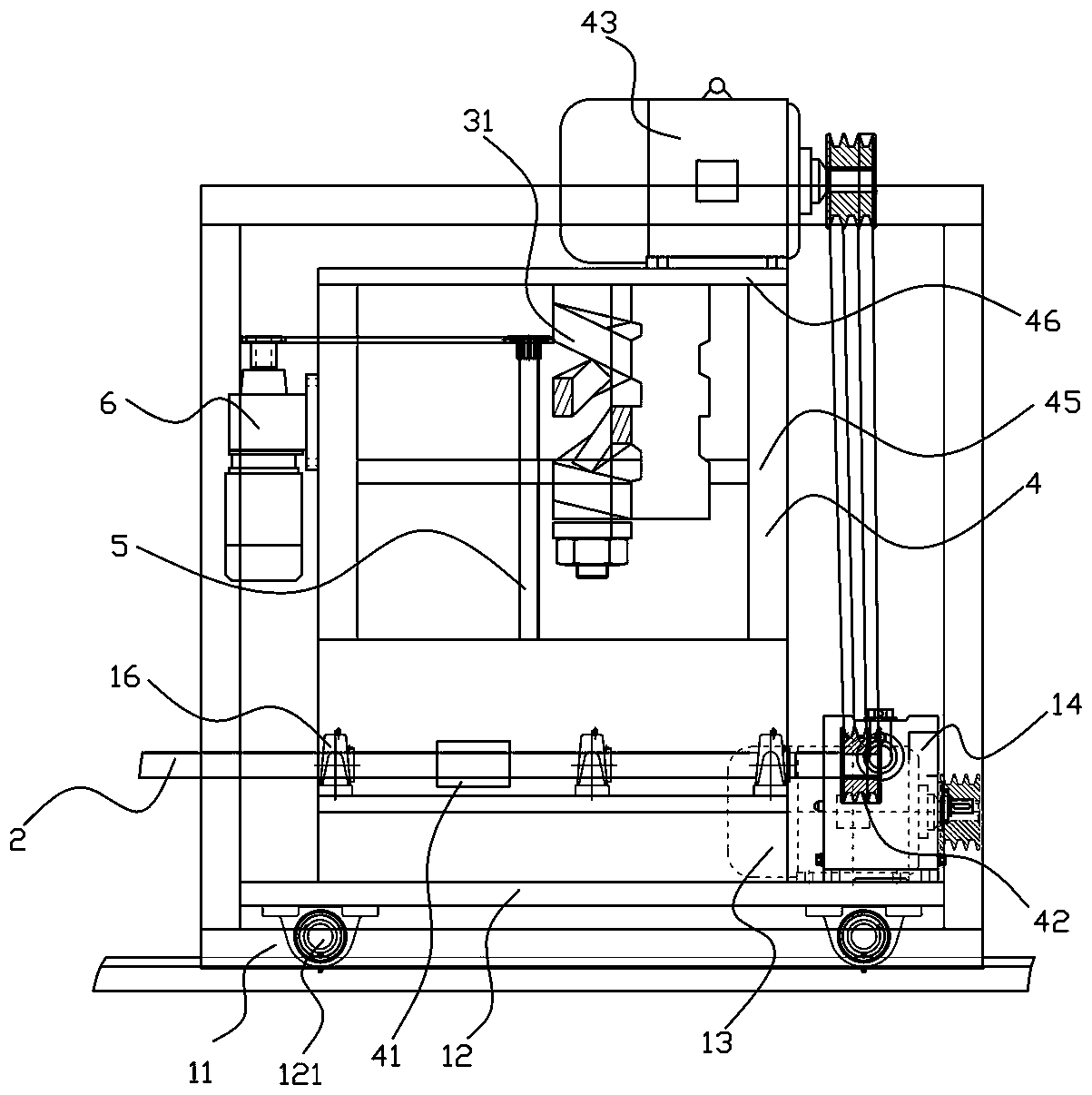

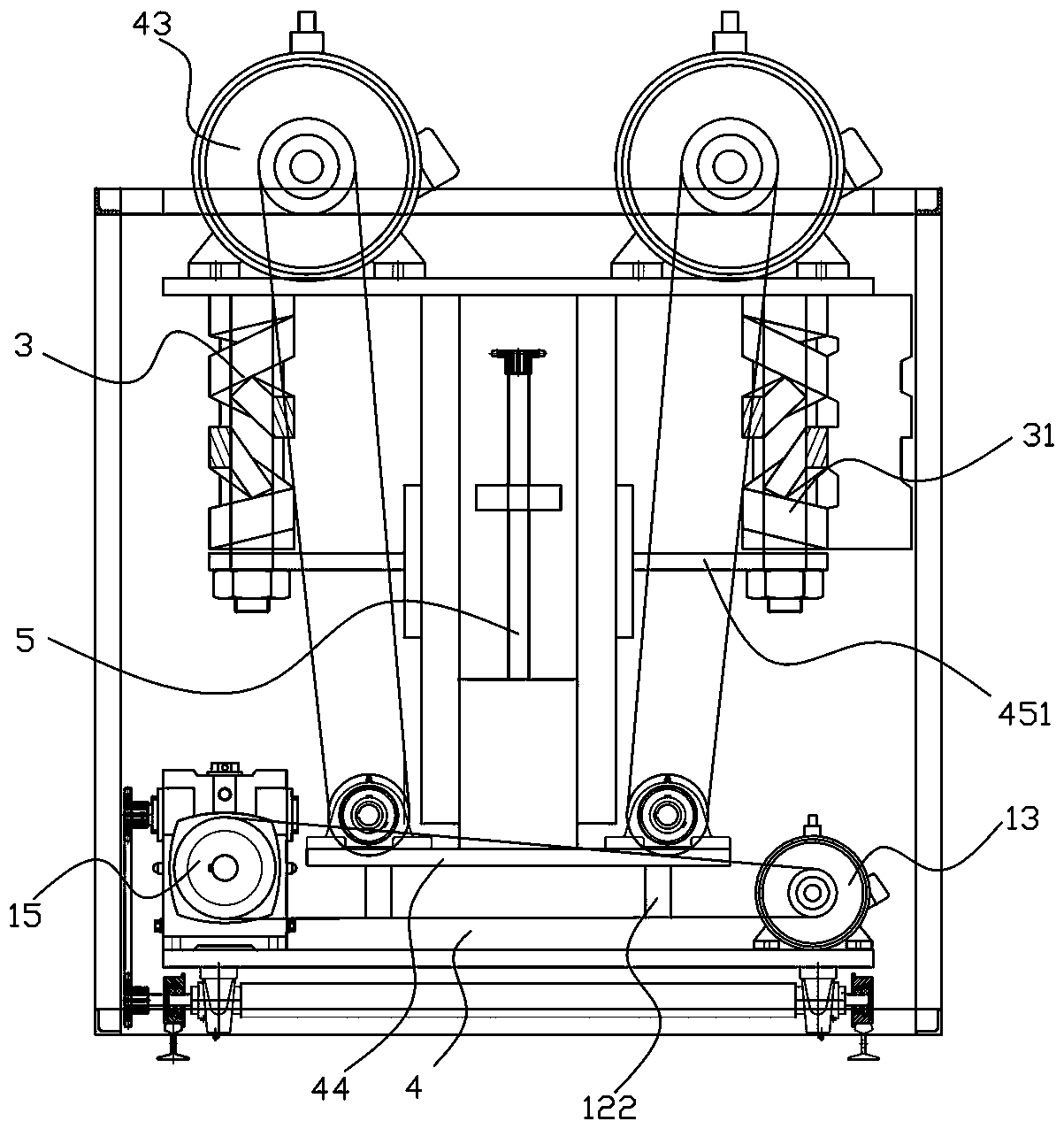

[0020] like figure 1 and figure 2 The shown precision grinding device for the inner surface of a steel pipe includes a traveling mechanism 1 , a throwing rod 2 , a driving mechanism for the throwing rod 2 and a damping mechanism 3 . The traveling mechanism 1 includes a track 11 and a trolley 12. The lower end of the trolley 12 is provided with a traveling wheel 121 rolling along the track 11, and the trolley 12 is provided with a traveling drive motor 13 for driving the traveling wheel 121 to rotate. There are two rails 11 parallel to each other, and four road wheels 121 are symmetrically distributed on the rails 11 . The trolley 12 is provided with a mounting frame 4, the mounting frame 4 is provided with a fixture 41 for fixing the throwing rod 2, a driven wheel 42 positioned at the end of the throwing rod 2, and a main motor 43 for driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com