Hard rail type gantry numerical control milling machine

A CNC milling machine and hard rail technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve problems such as weak stability, high maintenance costs, and damage to rolling line rails, so as to reduce machining accuracy The effect of large contact area of the guide rail and the smooth operation of the machine tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

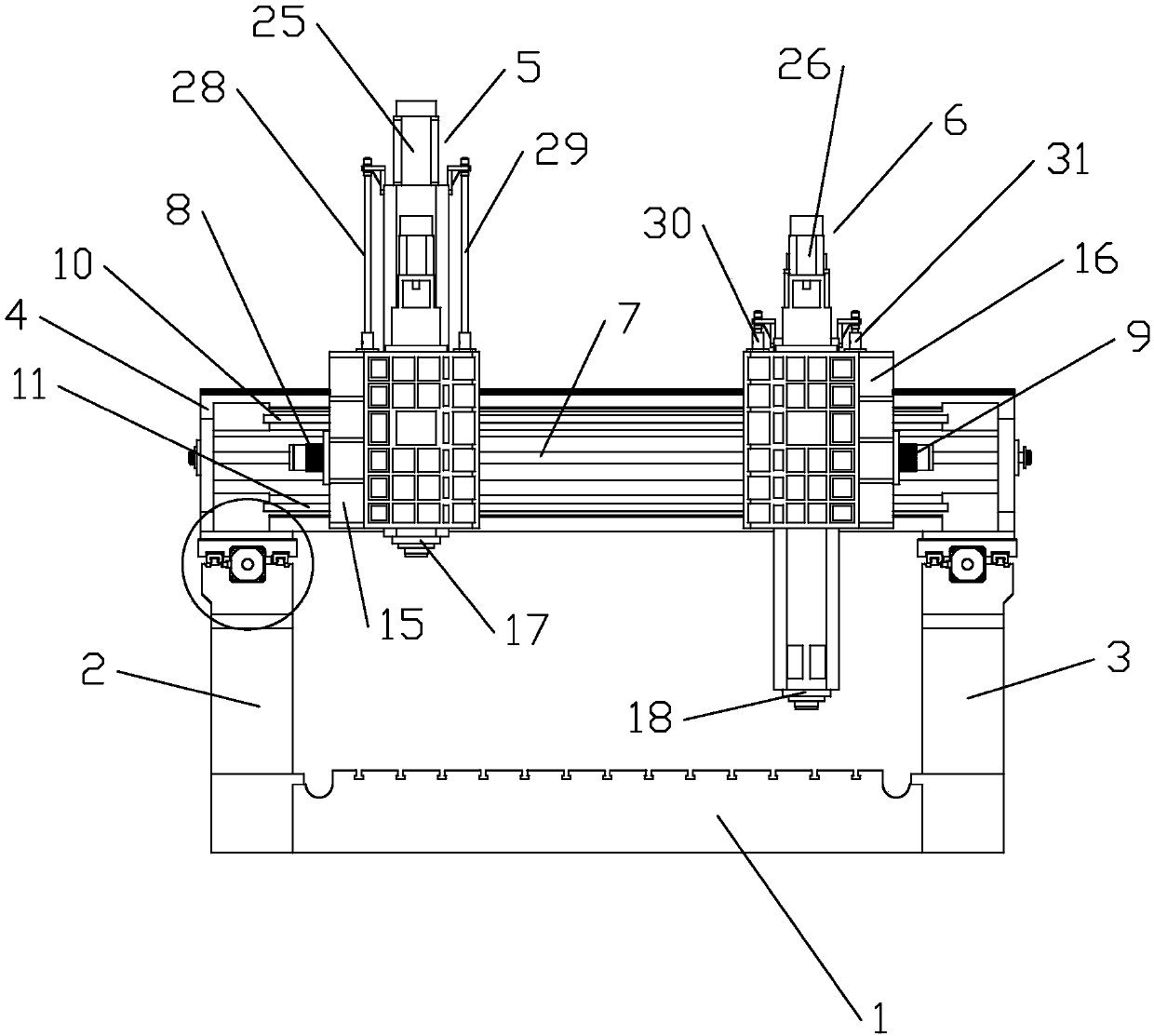

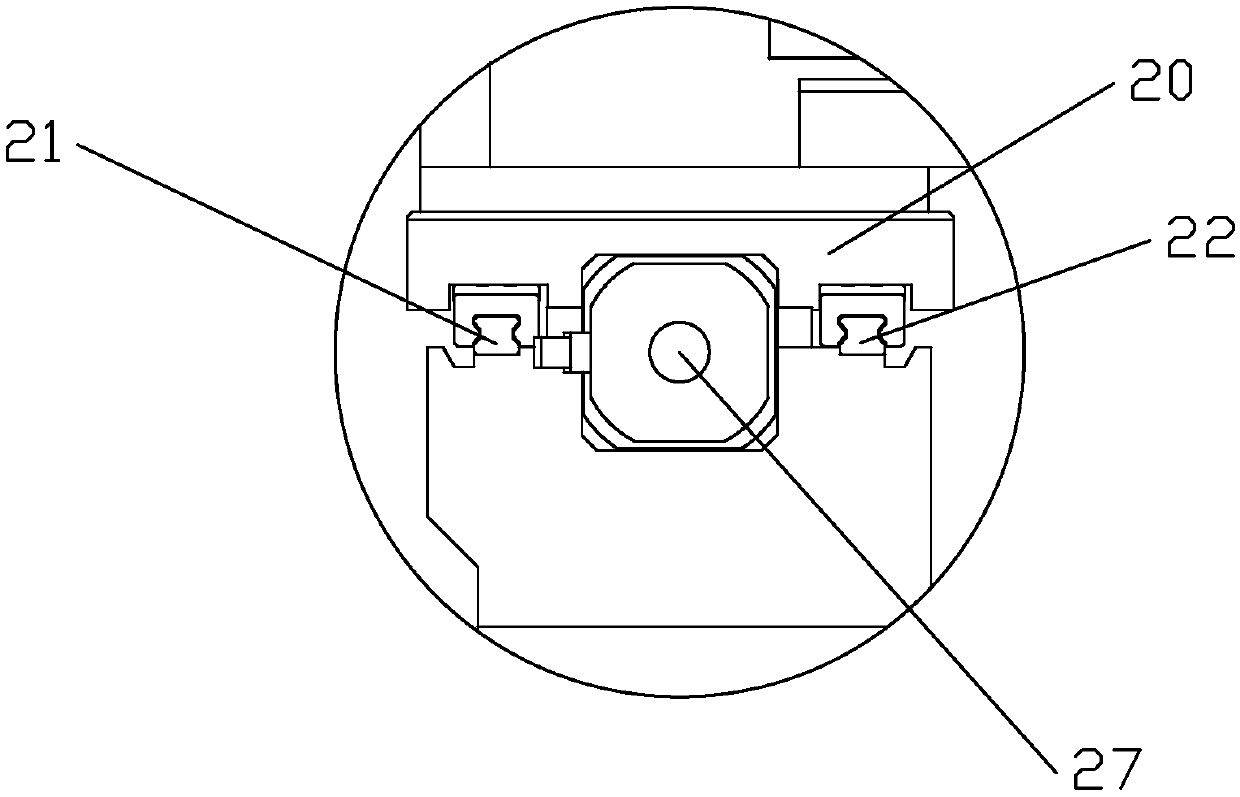

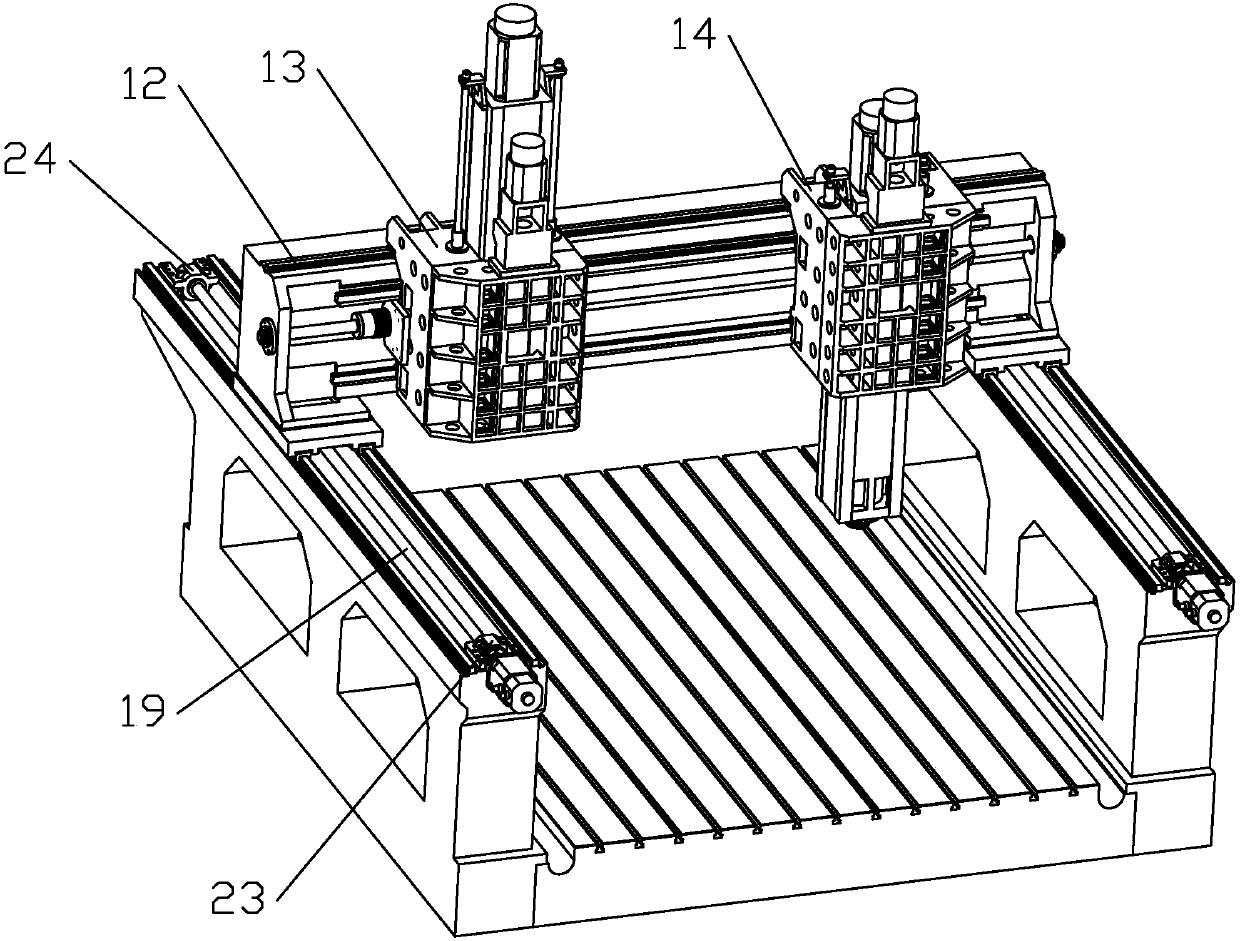

[0020] Such as Figure 1 to Figure 3 As shown, one of the embodiments provided by the present invention, a hard rail type gantry CNC milling machine, includes a workbench body 1, a gantry frame and a processing device, and the gantry frame includes left and right sides respectively fixed on the workbench body 1. The first pillar 2 and the second pillar 3 on the right side, and the crossbeam 4, the first pillar 2 and the second pillar 3 are respectively connected to the two ends of the crossbeam 4 through a synchronous movable device, and the processing device includes The first Z-axis device 5 and the second Z-axis device 6 on the beam 4, the beam 4 is provided with a first guide rail 10 and a second guide rail 11 fixed on the front end surface of the beam 4, and a first guide rail 11 fixed on the upper end surface of the beam. Three guide rails 12, the first guide rail 10, the second guide rail 11 and the third guide rail 12 are sliding hard rail tracks with an inverted V-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com