Double-ended grinding machine

A double-end surface grinding machine and grinding technology, which is applied to grinding machines, grinding machine parts, and machine tools suitable for grinding workpiece planes, etc. Stable and firm, stable and firm clamping, and flexible processing of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

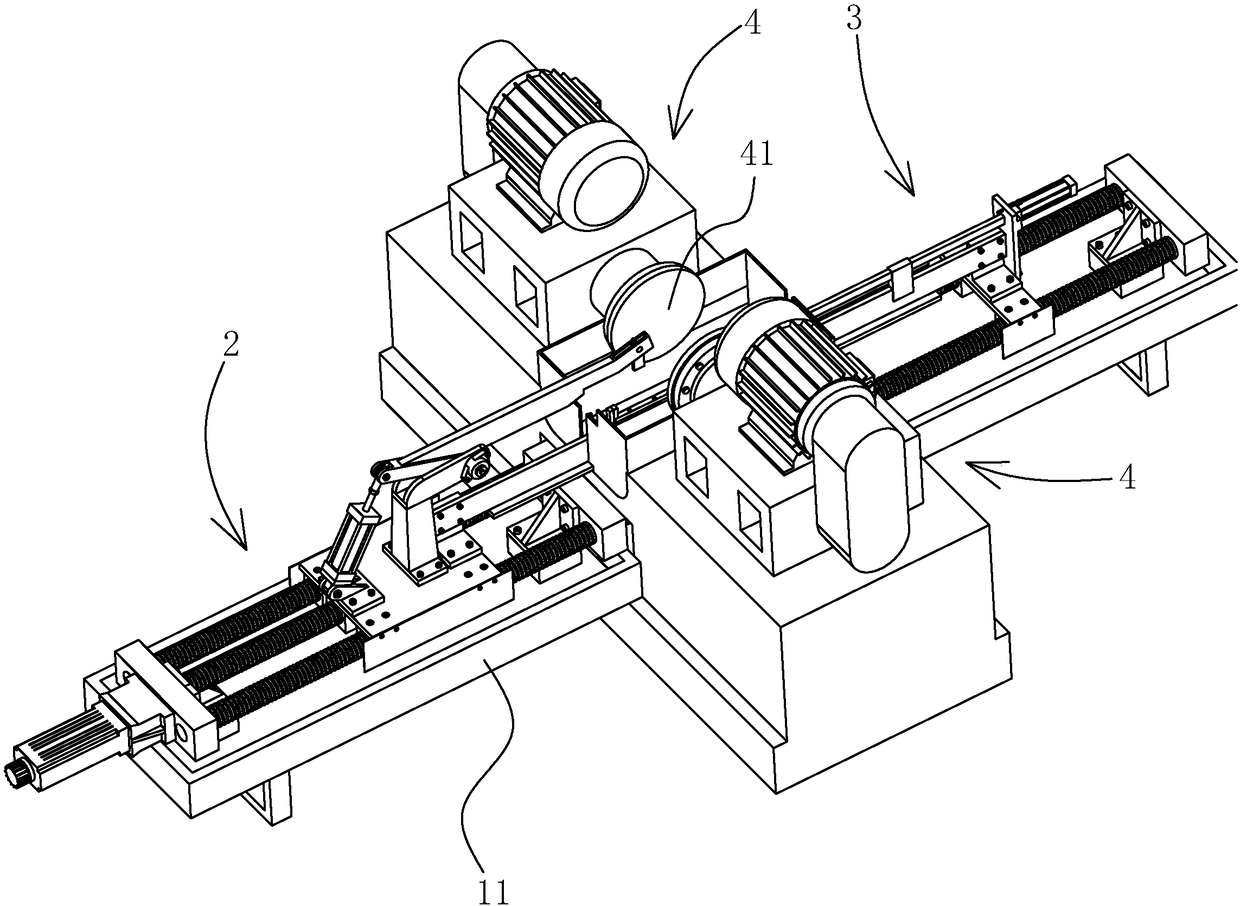

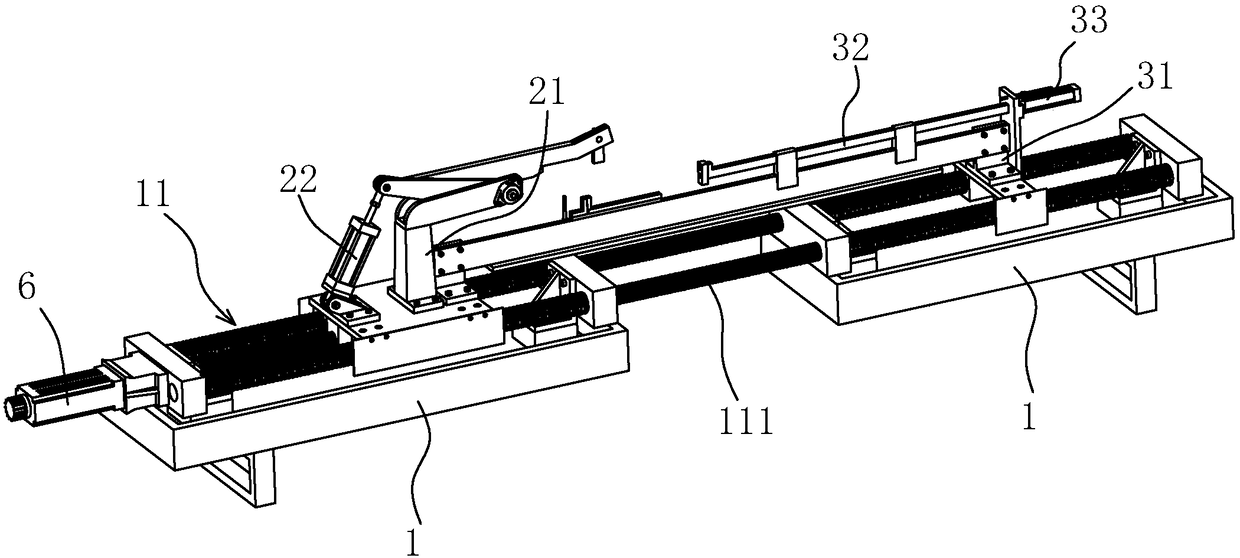

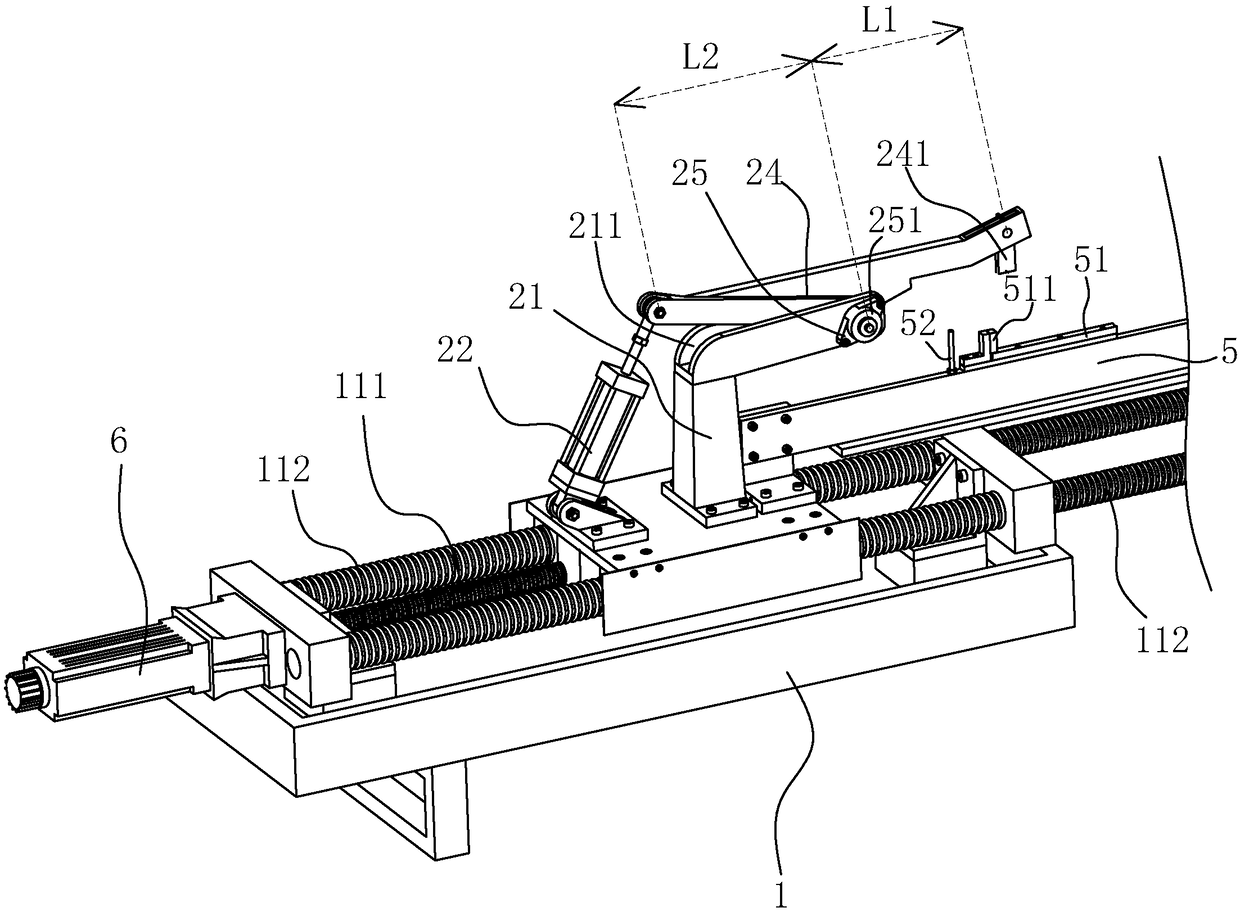

[0026] Please refer to figure 1 , the present embodiment provides a double-end surface grinding machine, which is suitable for simultaneous processing of the double-end surfaces of the workpiece. The material of the workpiece can be other materials such as magnetic steel. The device can clamp the workpiece in multiple directions. The lower workpiece is firmly clamped, the equipment runs stably, the machining accuracy is high, and it has the advantages of a high degree of automation.

[0027] combined with figure 2 , that is, it includes a clamping device 2 for clamping the workpiece in the vertical direction, and additionally includes a horizontal clamping device 3 for clamping the workpiece in the horizontal direction. Further, after the workpiece is sent to the processing position, the grinding head devices 4 on both sides feed and grind the workpiece at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com