Rubber layer online automatic eccentric adjustment device and eccentric adjustment method

An automatic adjustment device and rubber layer technology, applied to coatings, other household appliances, household appliances, etc., can solve the problems of low eccentricity adjustment efficiency and adjustment accuracy, rubber layer eccentricity detection is not timely, etc., to achieve eccentricity adjustment efficiency High, eccentricity adjustment efficiency and high adjustment accuracy, the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

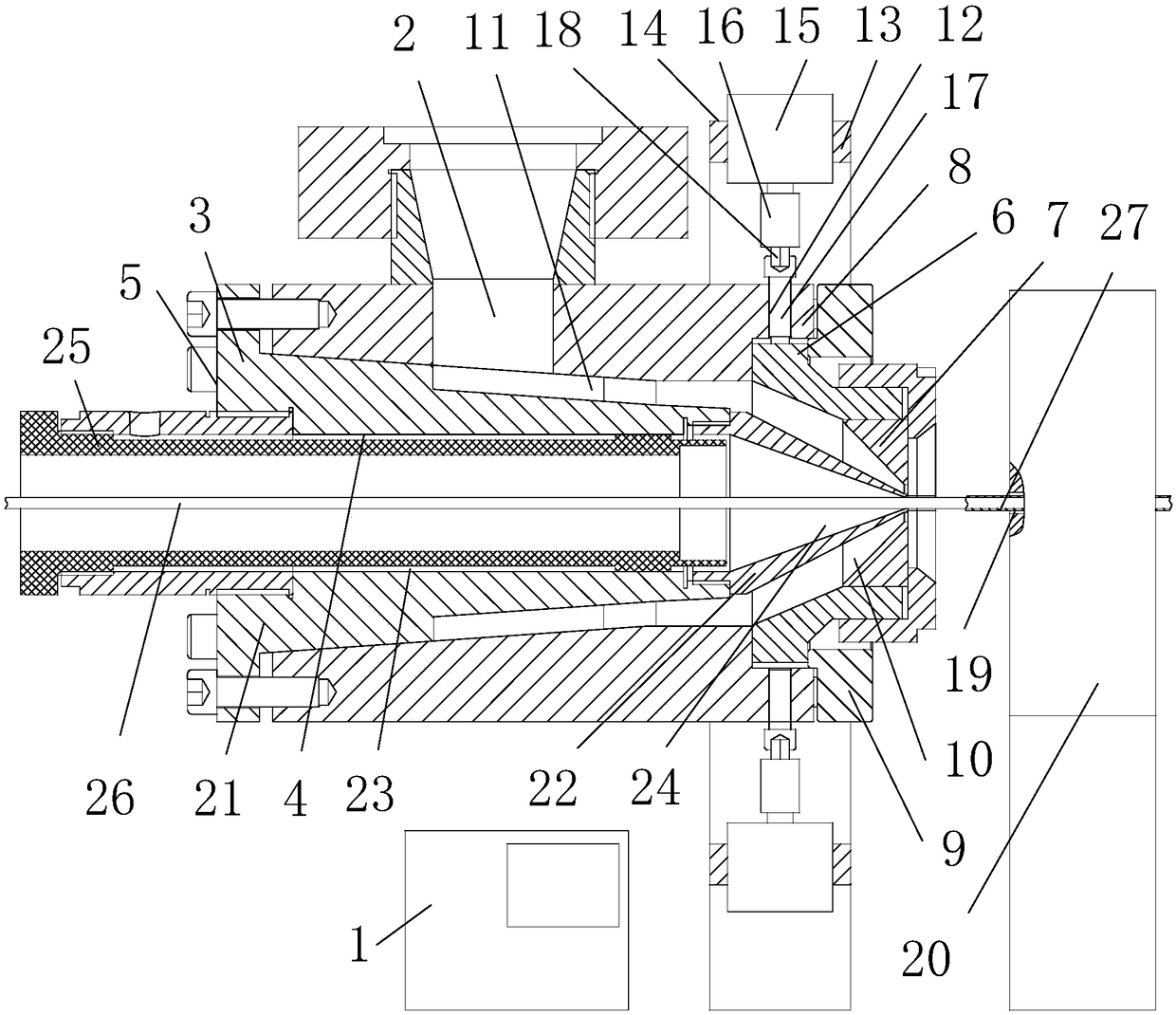

[0015] as attached figure 1 Shown: an on-line automatic adjustment device for rubber layer eccentricity, including: machine head, an online thickness detector arranged on the front side of the machine head, an eccentric adjustment device, and a controller 1; the machine head includes: rubber inlet holes 2 arranged on the side wall The body 3, the inner tube 5 which is installed in the body 3 and has a middle hole 4, is sleeved outside the front end of the inner tube 5 and has a die 7 with an outer convex ring 6 at the rear end, and is set at the front end of the body 3 and has an inner diameter of Adjusting convex ring 8 that is larger than the outer diameter of the outer convex ring 6, the pressure ring 9 that blocks the front end of the outer convex ring 6 and is connected with the front end screw of the adjusting convex ring 8, and four adjusting screws; the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com