Automatic soap packing device

A soap and carton technology, applied in the field of automated production equipment, can solve the problems of physical property limitations of soap and incomplete matching of finished products, and achieve the effects of reduced extrusion, precise shaping, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In this embodiment, the boxing specification of soap is that each box of soap is individually packaged, and each box has 3 layers in total, and the specification of each layer is 3 rows and 3 columns, and each individually packaged soap unit includes three pieces of soap.

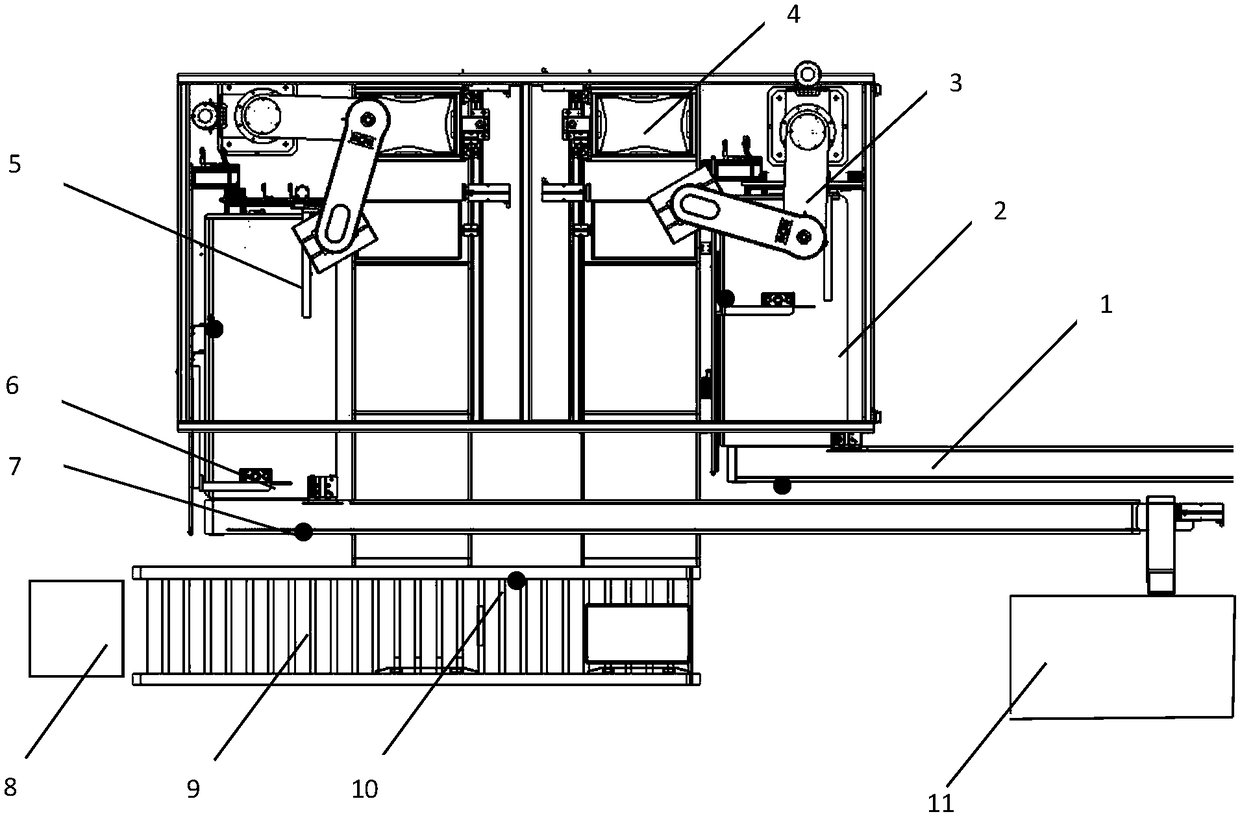

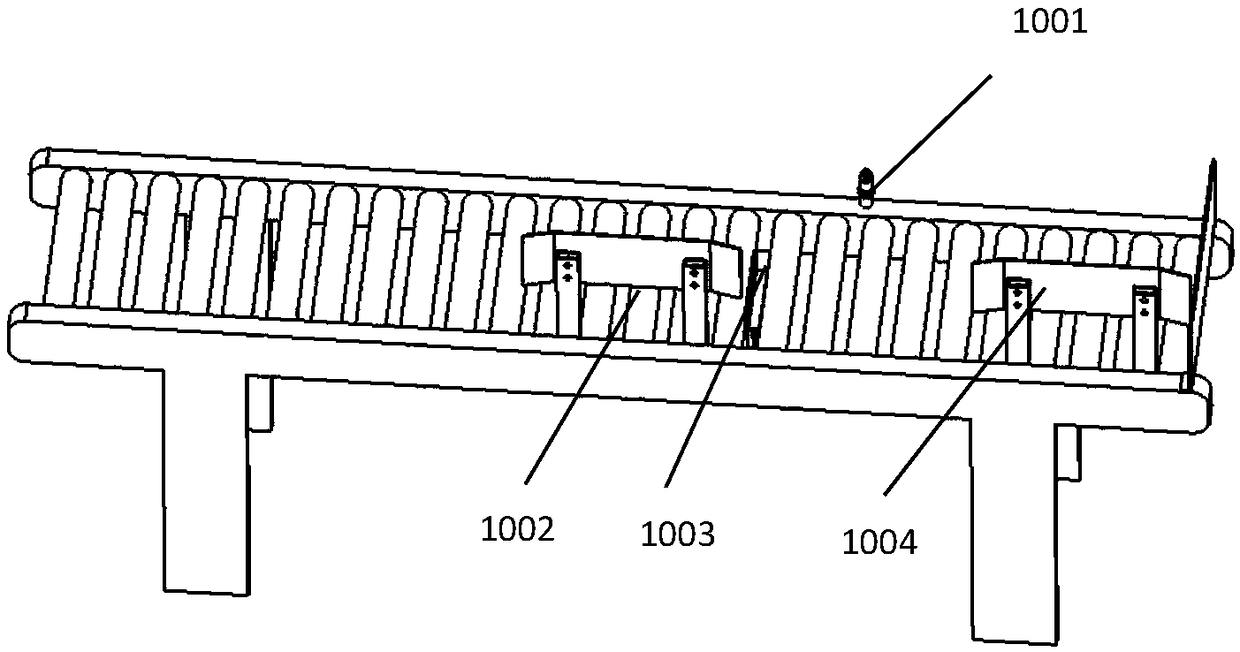

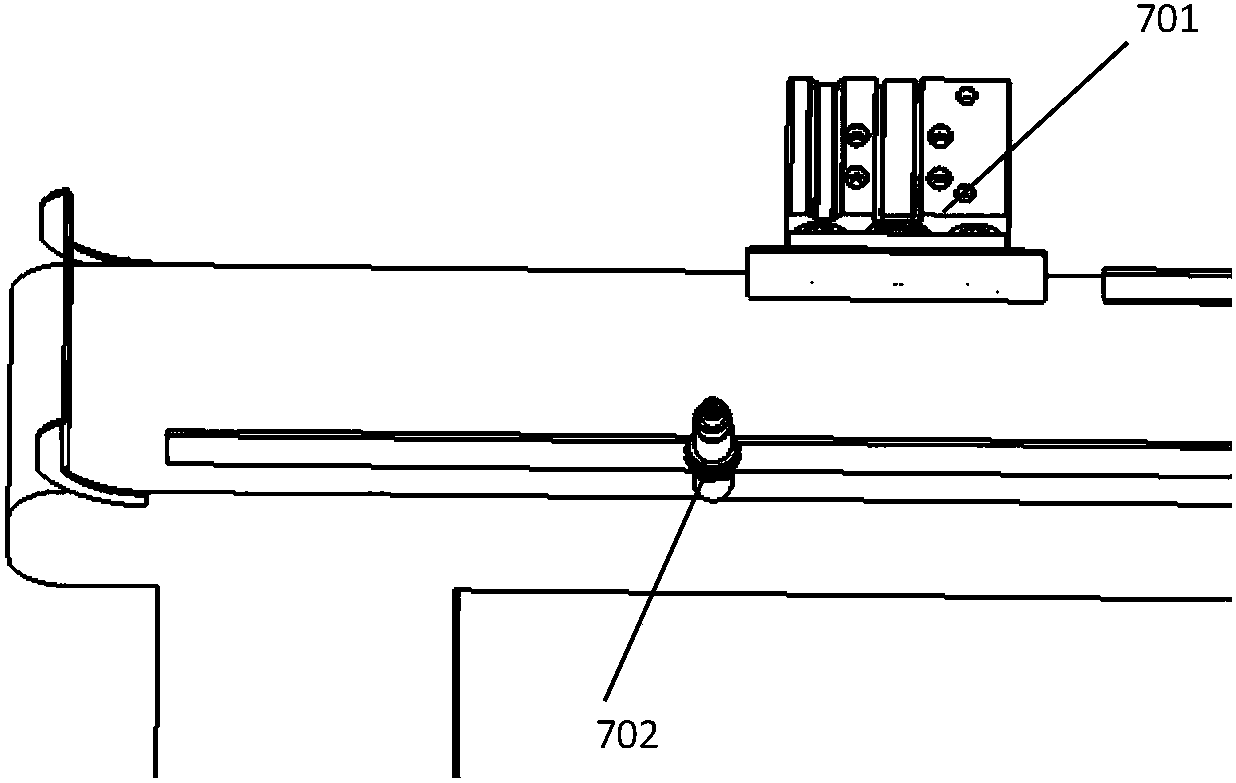

[0021] Such as figure 1 As shown, a soap automatic packing device includes two soap conveying lines 1, a carton conveying line, two handling robots 3 and two buffer waiting areas 2, and the input ends of the two soap conveying lines 1 are respectively connected to the soap plastic sealing machine The output ends of 11 are connected, the output end of the soap conveying line 1 is provided with an alignment mechanism 5, and the traverse mechanism 6 is arranged between the output end of the soap conveying line 1 and the input end of the buffer waiting area 2, and the machines of the two buffer waiting areas 2 Shaping mechanisms 5 are arranged on the shelves, and the shaping mechanisms 5 are arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com