Pressing plate mechanism of in-out pallet

A technology of pressing plates and pallets, which is applied in the direction of conveyor objects, furnaces, charge manipulation, etc., and can solve the problems of affecting the quality of electronic component placement, deformation of thin PCB circuit boards, and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

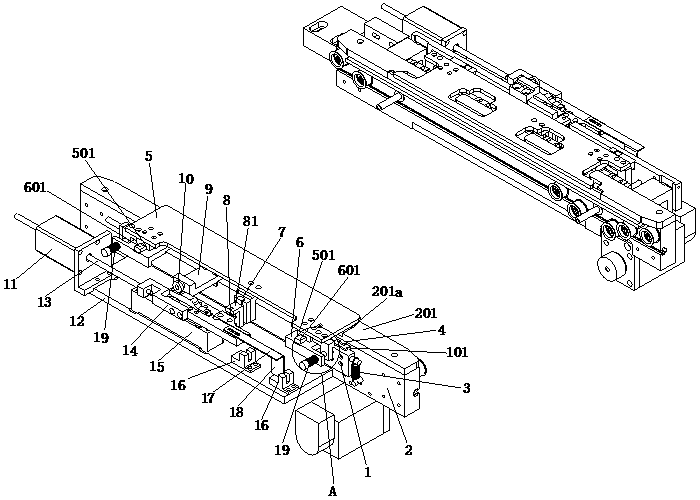

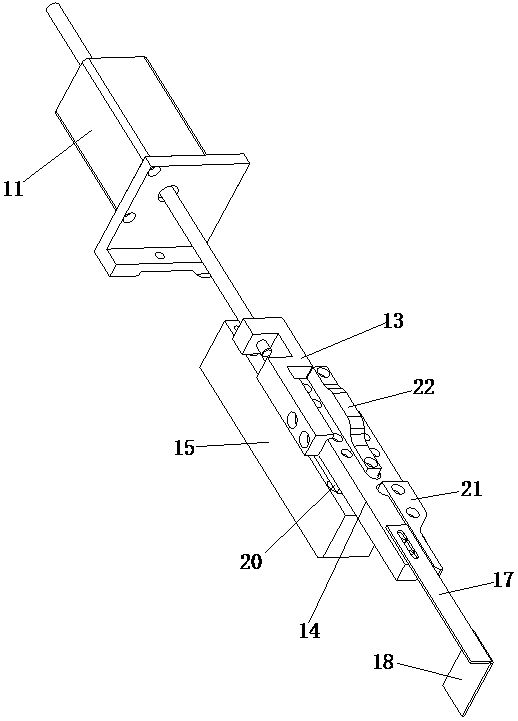

[0045] Such as Figures 1 to 3 As shown, a pressing plate mechanism for entering and exiting a pallet according to the present invention includes two pressing plate assemblies, and the pressing plate assemblies are used in pairs, and this example is preferably used symmetrically. The pressing plate assembly includes a lifting plate 1 , an in-out plate track 2 and a PCB pressing plate 5 . The PCB circuit board is not shown in the figure and is sent to the directly below the printing screen layout through the conveyor belts on the two entry and exit board tracks 2 .

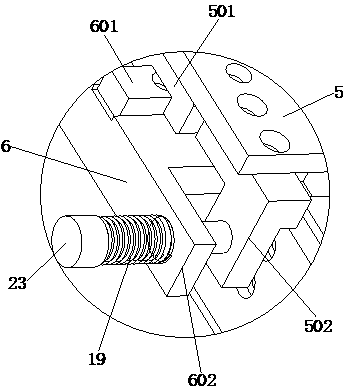

[0046]The PCB pressing plate 5 is connected with the lifting plate 1 through a translation guide assembly, a dynamic positioning plate 12 is provided on the access plate track 2, and a linear sliding device is provided on the dynamic positioning plate 12; the linear sliding device includes a linear The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com