Mounting device

A placement device and placement head technology, used in transportation and packaging, object supply, electrical components, etc., can solve the problem that the placement accuracy and assembly firmness cannot be effectively guaranteed, the edge shape of the back cover is inconsistent, and the assembly equipment is very poor. Difficult to fit and other problems, to achieve the effect of firm sticking, improving mounting effect, and efficient mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

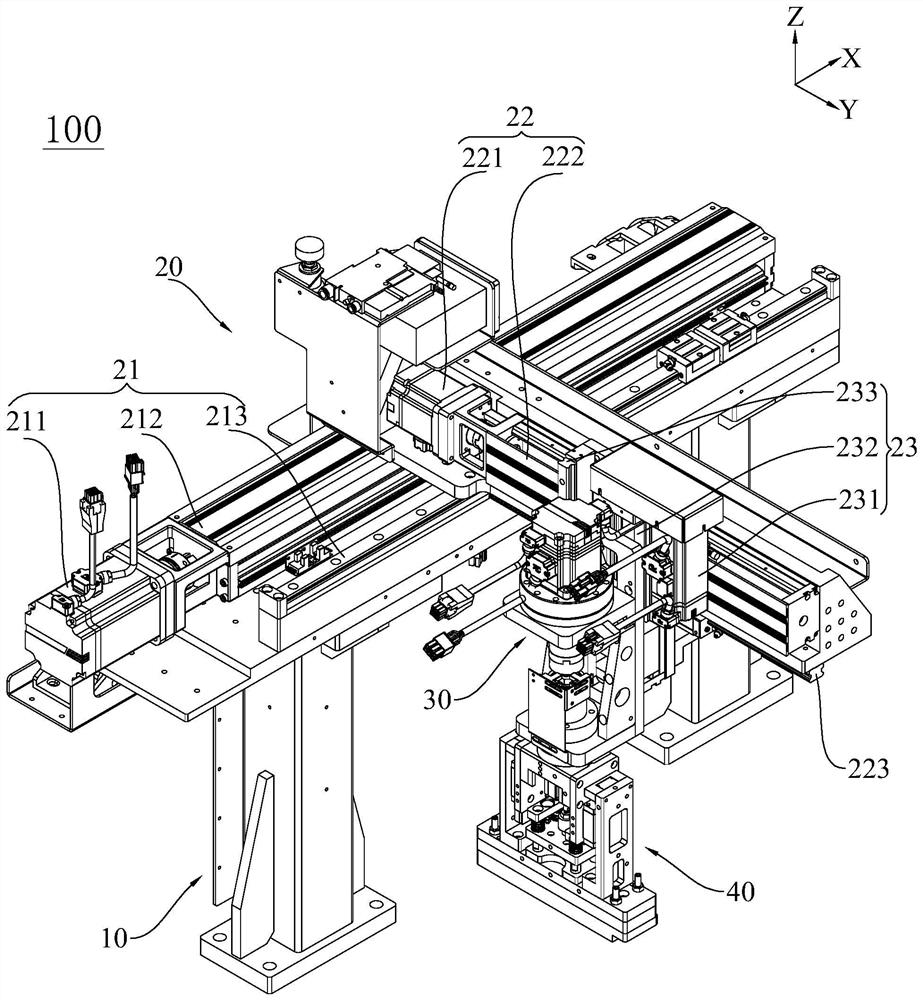

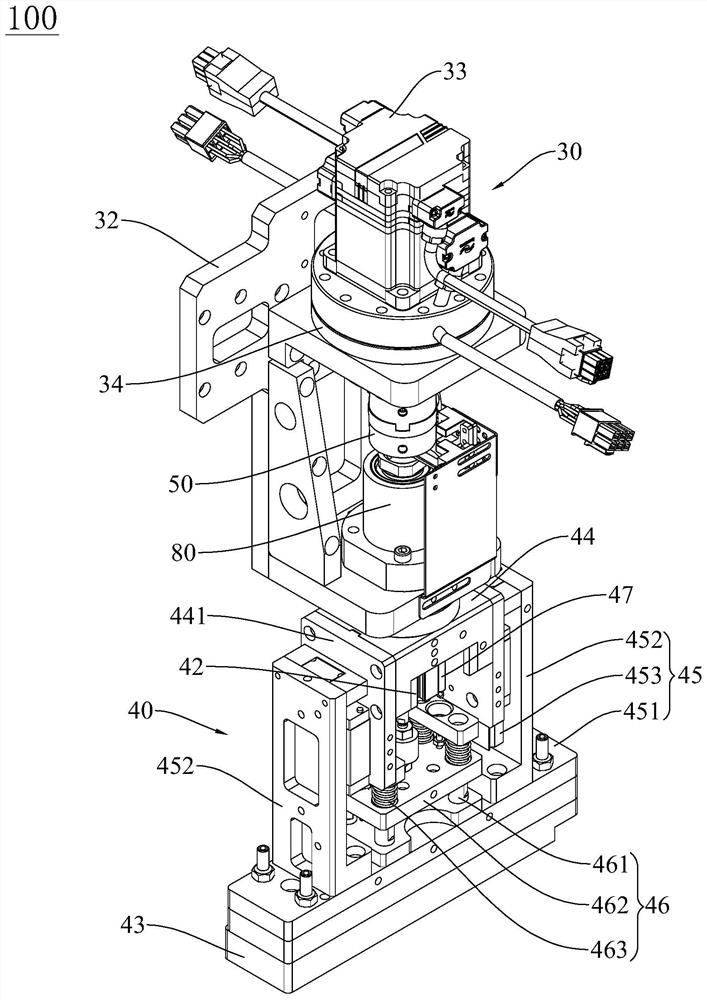

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

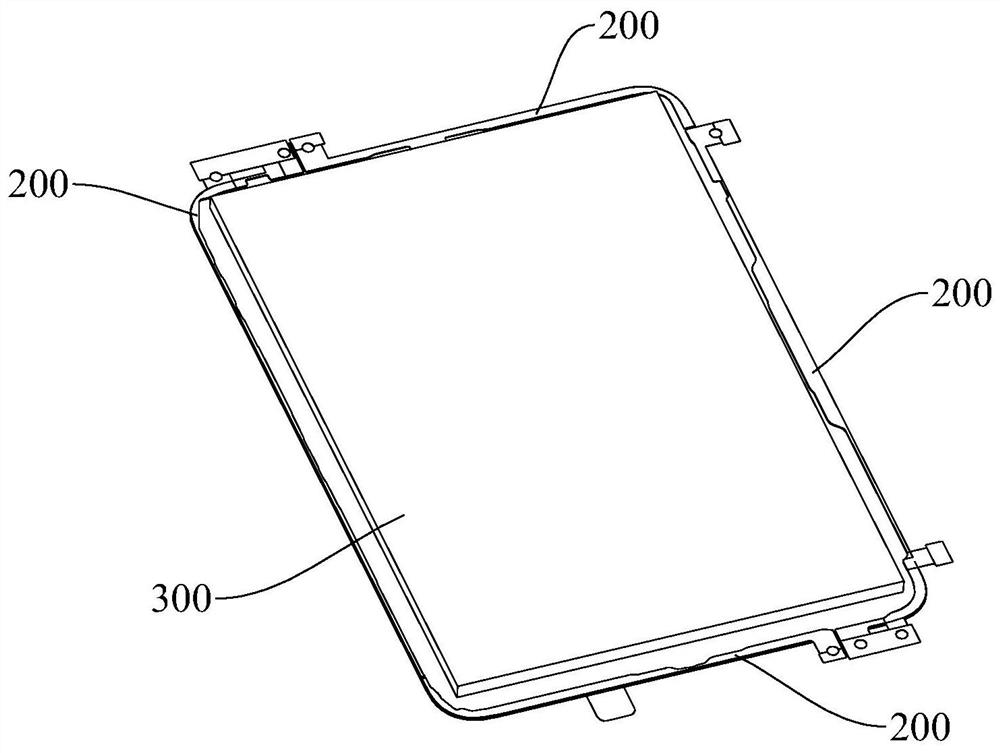

[0023] see Figure 1 to Figure 5 , the present invention provides a placement device 100, which is used to absorb and transfer thin and irregularly shaped adhesive strips 200, so as to paste and assemble them on the workpiece 300. In this application, the adhesive strips 200 are specifically double-sided The noodle strip has a certain degree of elasticity and is in the shape of a strip as a whole. The workpiece 300 is specifically the back cover of the tablet computer. Four adhesive strips 200 need to be mounted on the circumferential edge of the back cover to facilitate the mounting of the screen of the tablet computer. The shapes and sizes of the four rubber strips 200 correspond to the shapes and sizes of the edges around the back cover, and the shapes and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com