High-speed bagged material stacking machine

A palletizer and material technology, applied in the field of high-speed bagged material palletizers, can solve the problems of low palletizing capacity, waste of human resources, poor stacking and shaping ability, etc., to ensure stable operation and achieve accurate Line up, run smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

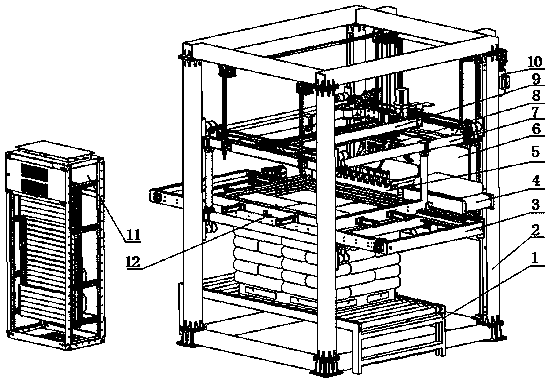

[0021] Example: see Figure 1-Figure 5 .

[0022] figure 1 Middle, 1-heavy-load conveying mechanism, 2-frame, 3-code layer shaping mechanism, 4-bag feeding mechanism, 5-to-be-grabbed mechanism, 6-counterweight lifting mechanism, 7-working frame, 8-joint Gripper mechanism, 9-beam moving mechanism, 10-lifting power mechanism, 11-electric control mechanism, 12-pneumatic mechanism.

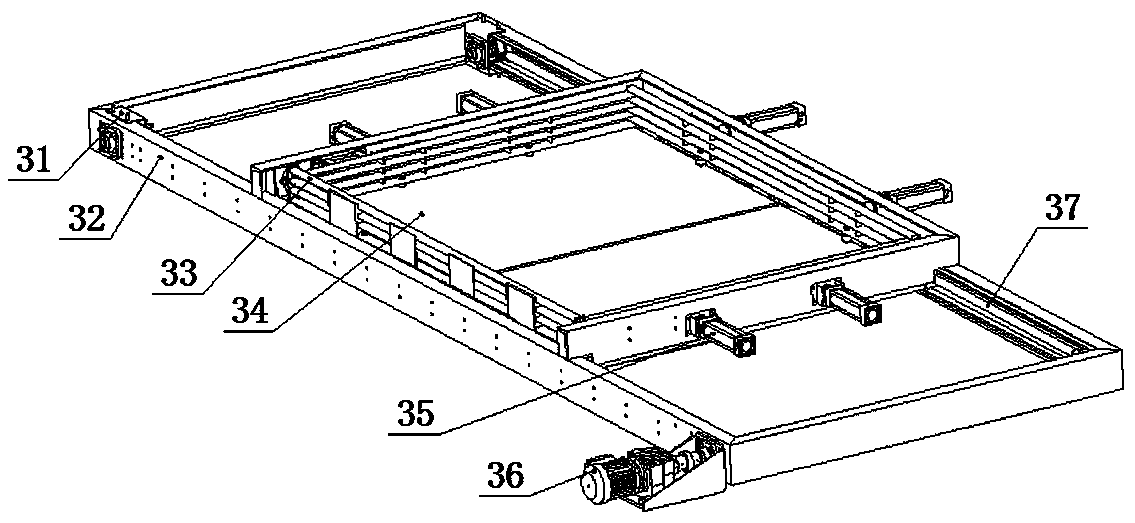

[0023] figure 2 Among them, 31-transmission tensioning mechanism, 32-yard frame, 33-extruding package mechanism, 34-yard supporting plate, 35-extruding package power mechanism, 36-supporting plate power mechanism, 37-supporting plate guiding mechanism.

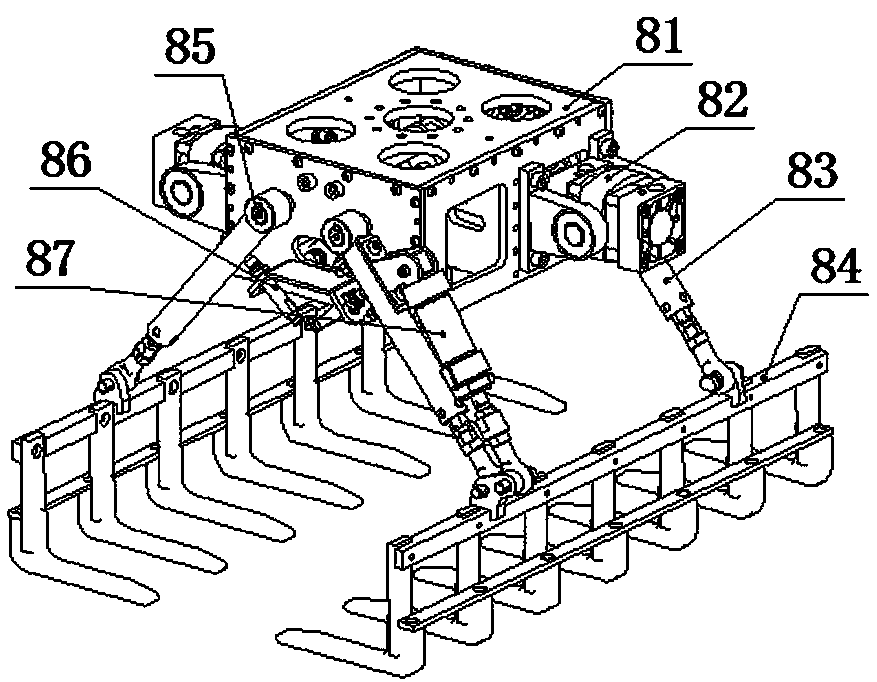

[0024] image 3 Among them, 81-installation frame, 82-joint one pneumatic mechanism, 83-joint force arm, 84-joint grasping teeth, 85-rotary shaft, 86-shock absorbing mechanism, 87-joint two pneumatic mechanism.

[0025] Figure 4 Middle, 51-upper frame, 52-roller conveying mechanism, 53-lifting force arm mechanism, 54-lower frame, 55-lifting pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com