Self-lubricating rotation chain for escalator

A self-lubricating, escalator technology, applied to escalators, chain rings, chain components, etc., can solve the problems of plastic sliding bearing wear, escalator rust, rolling bearing sticking, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

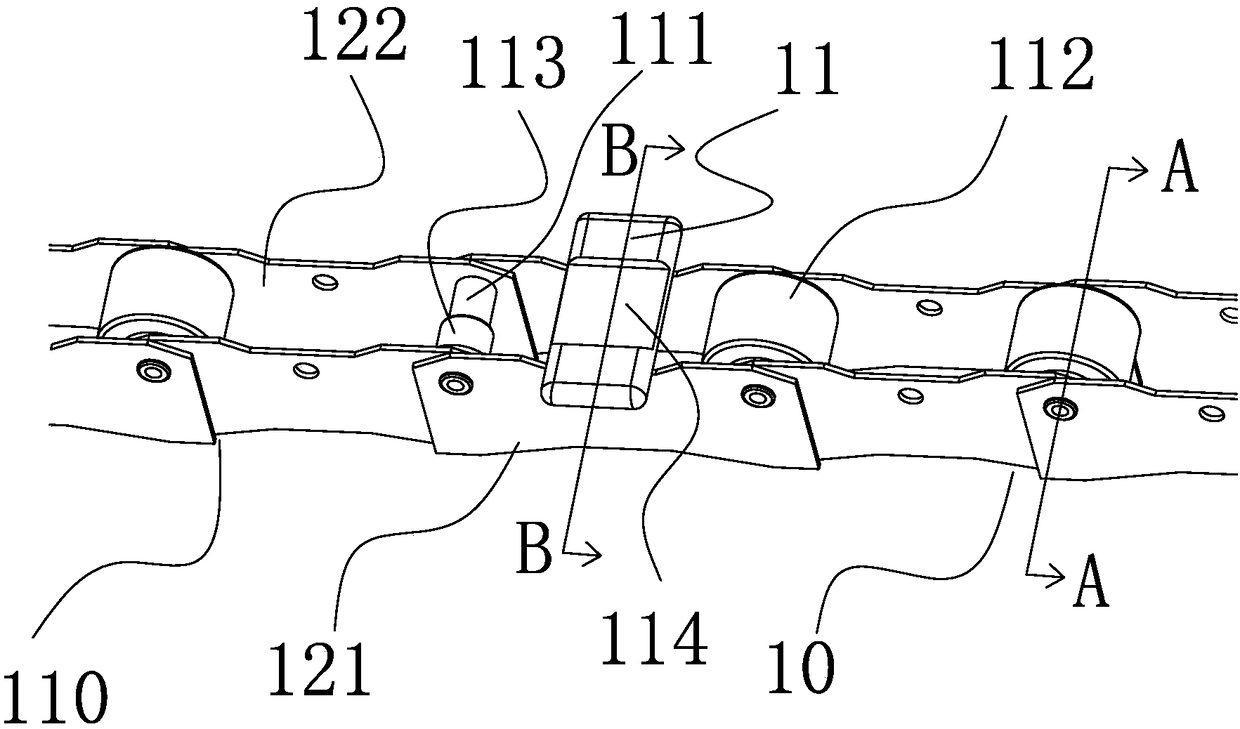

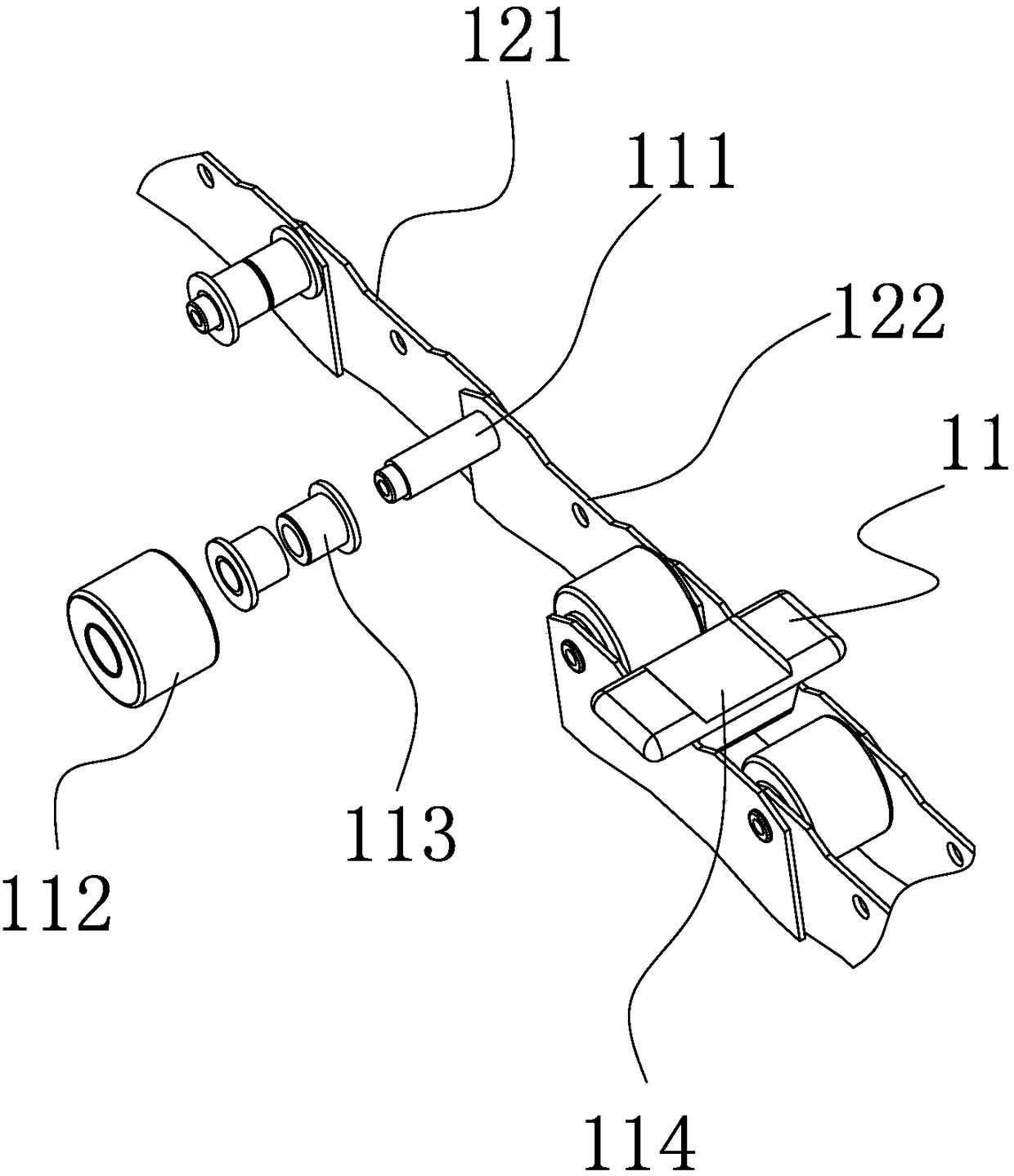

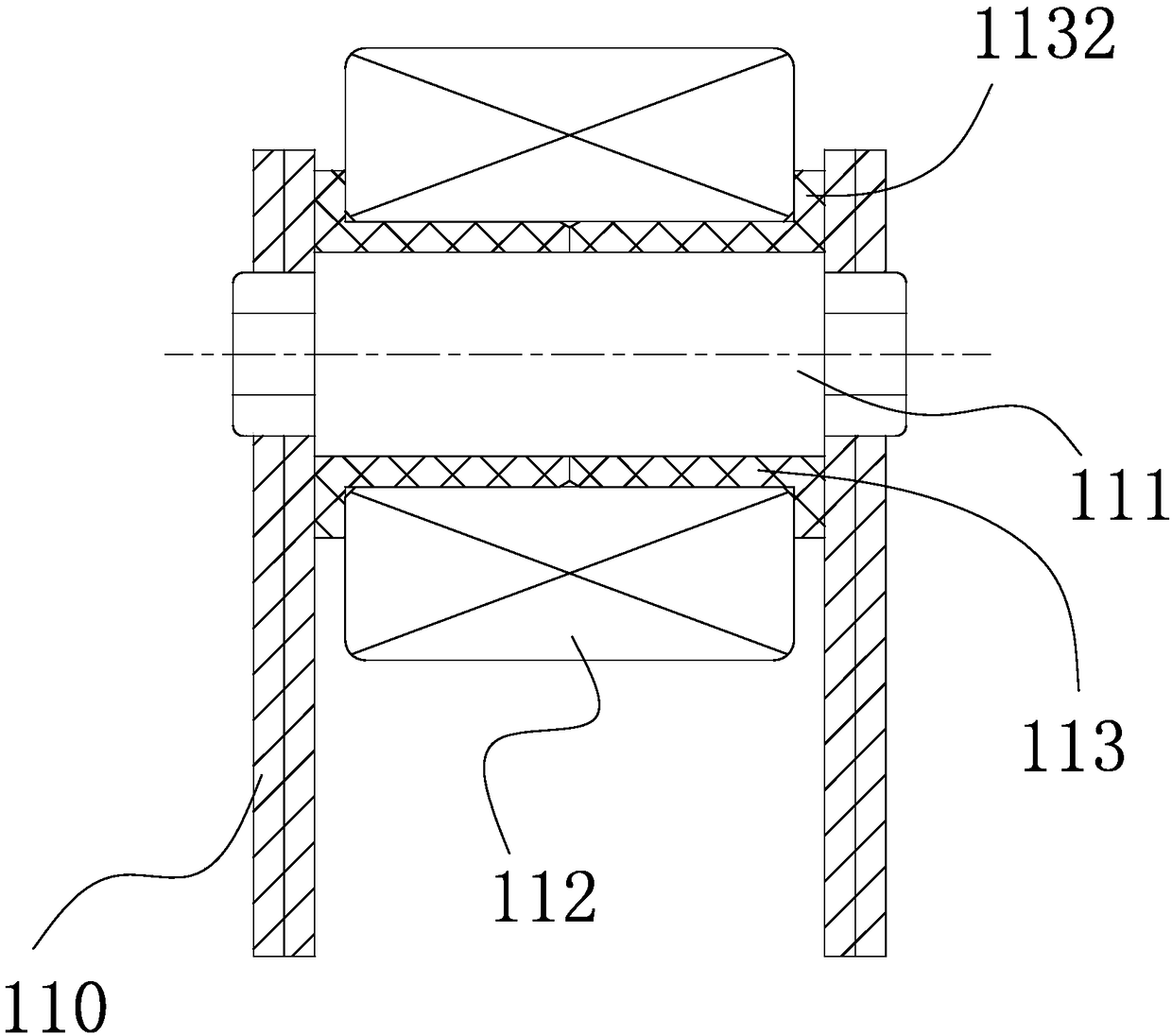

[0024] Please refer to figure 1 and figure 2 , which is a self-lubricating escalator revolving chain provided by the present invention, used for receiving and guiding the rubber protective belt of the escalator, including several revolving chain link units 10, the revolving chain link unit 10 includes two metal or alloy-made link plate groups 110, link pins 111, rollers 112 and self-lubricating plastic sliding bearings 113, the two link plate groups 110 are correspondingly provided with pin shaft holes, and the link plate groups 110 are respectively located in the Both ends of the roller 112 are provided with through holes along the axial direction.

[0025] The link plate group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com