A kind of hydrogenation method of silicon tetrachloride

A technology of silicon tetrachloride and hydrogen, applied in the direction of silicon halide compounds, chemical instruments and methods, halosilane, etc., can solve problems affecting product quality, increasing impurity base, reducing material purity, etc., to reduce temperature and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

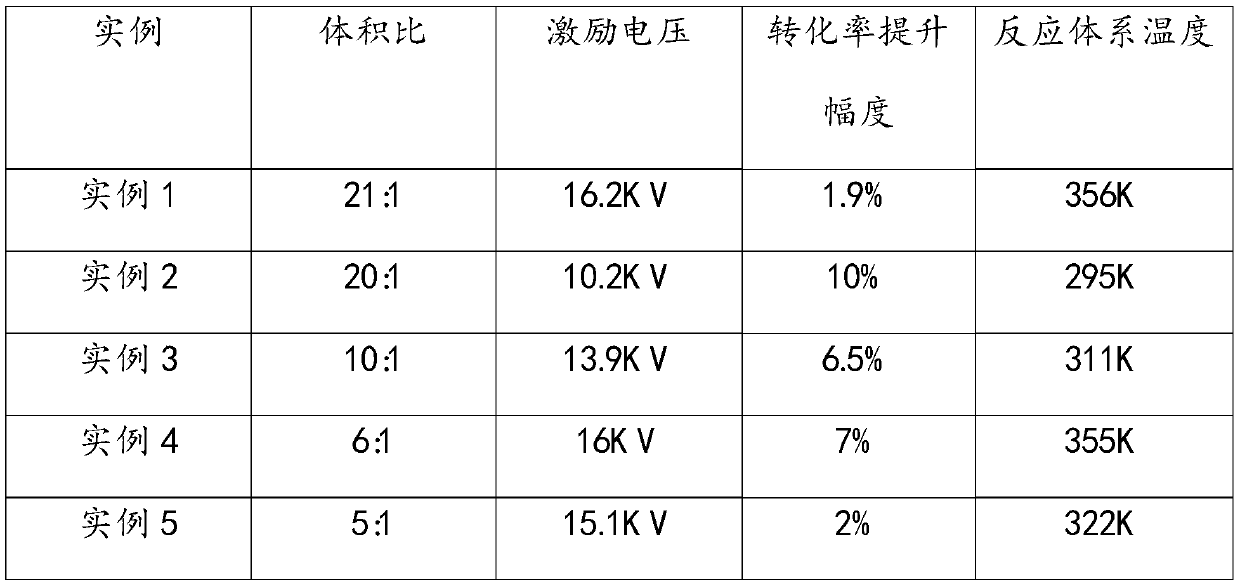

Examples

Embodiment 1

[0039] The invention relates to a method for hydrogenating silicon tetrachloride, which comprises introducing silicon tetrachloride and hydrogen gas into a gas discharge reactor filled with electromagnetic field adjustment materials and loaded metal catalysts, and reacting under the action of an electromagnetic field.

Embodiment 2

[0041] A method for hydrogenating silicon tetrachloride, which involves feeding silicon tetrachloride and hydrogen into a sliding arc discharge reactor filled with ferroelectric materials and loaded metal catalysts, and reacting under the action of an electromagnetic field;

[0042] Among them, the volume ratio of the supported metal catalyst to the ferroelectric material is 20:1, and the molar ratio of hydrogen to silicon tetrachloride is 5:1.

Embodiment 3

[0044] A hydrogenation method of silicon tetrachloride, filled with BaTiO 3 and in SiO 2 Silicon tetrachloride and hydrogen are introduced into a dielectric barrier discharge reactor loaded with metal catalysts loaded with iron catalysts, and react under the action of an electromagnetic field;

[0045] Among them, the supported metal catalyst and BaTiO 3 The volume ratio of hydrogen and silicon tetrachloride is 6:1, and the molar ratio of hydrogen and silicon tetrachloride is 25:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com