Grouting pressure control device

A pressure control and grouting technology, applied in construction, infrastructure engineering and other directions, can solve the problems of stratum lifting, low degree of automation, low control precision, etc., and achieve the effect of reducing frictional resistance of sealing and flexible up and down movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

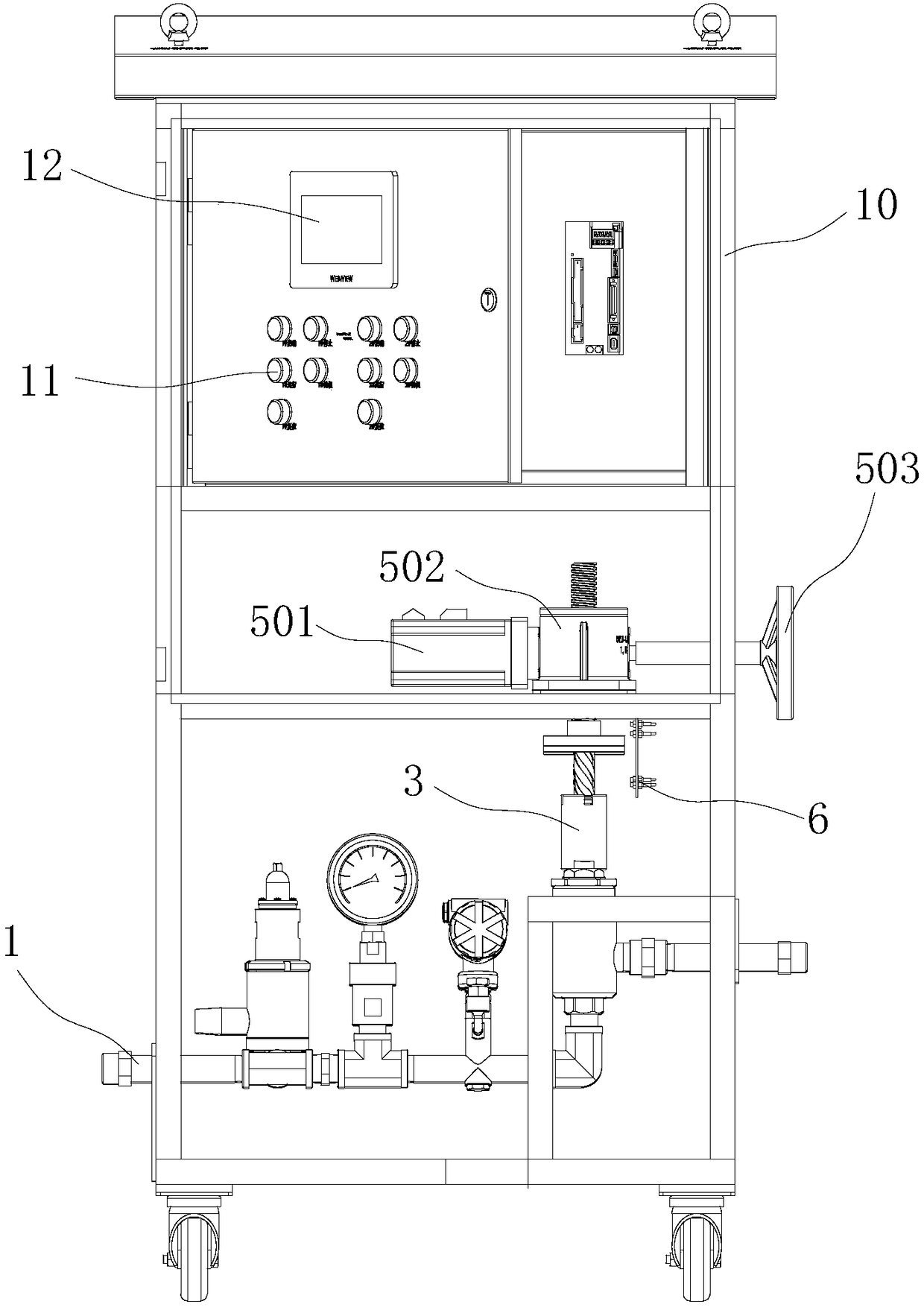

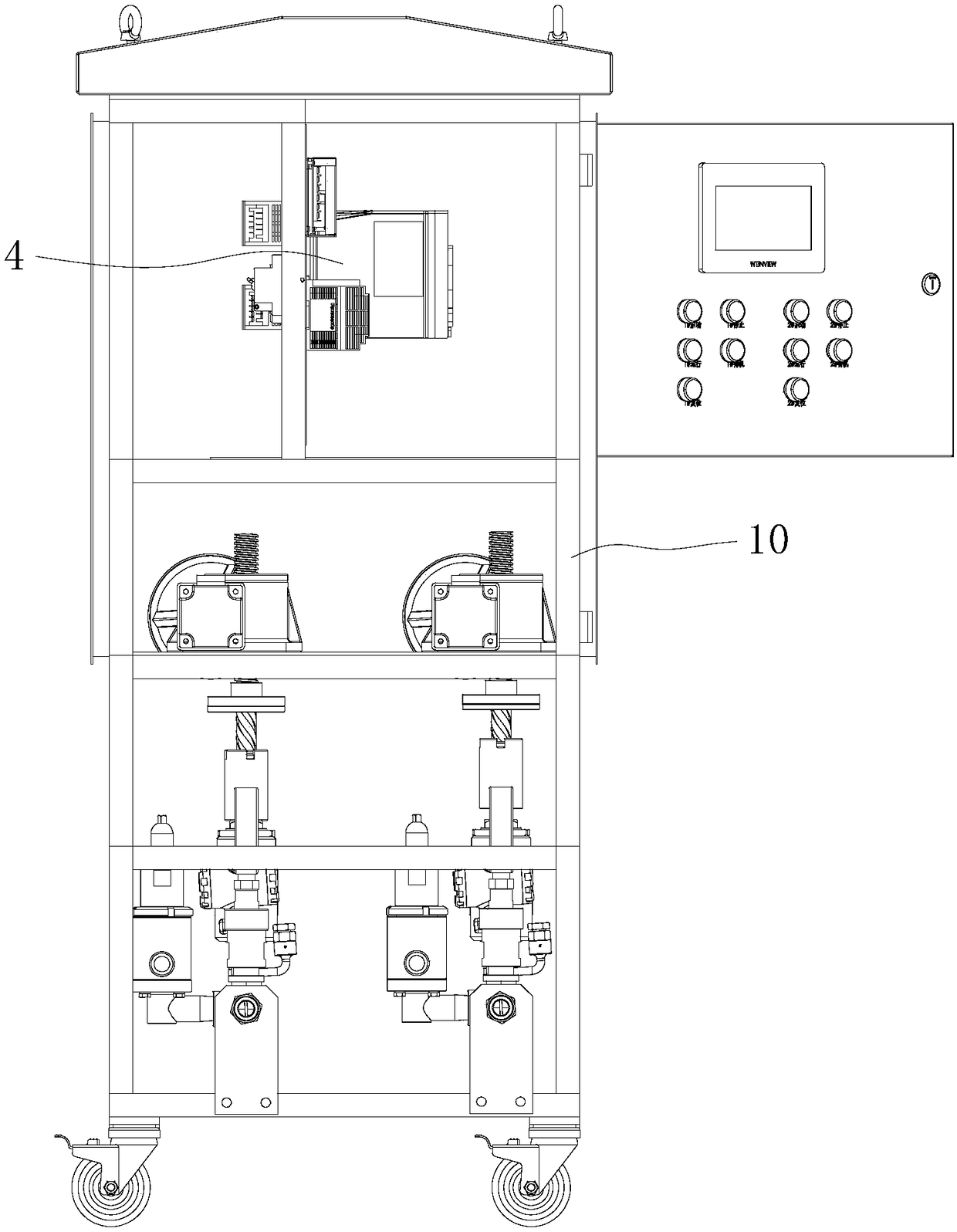

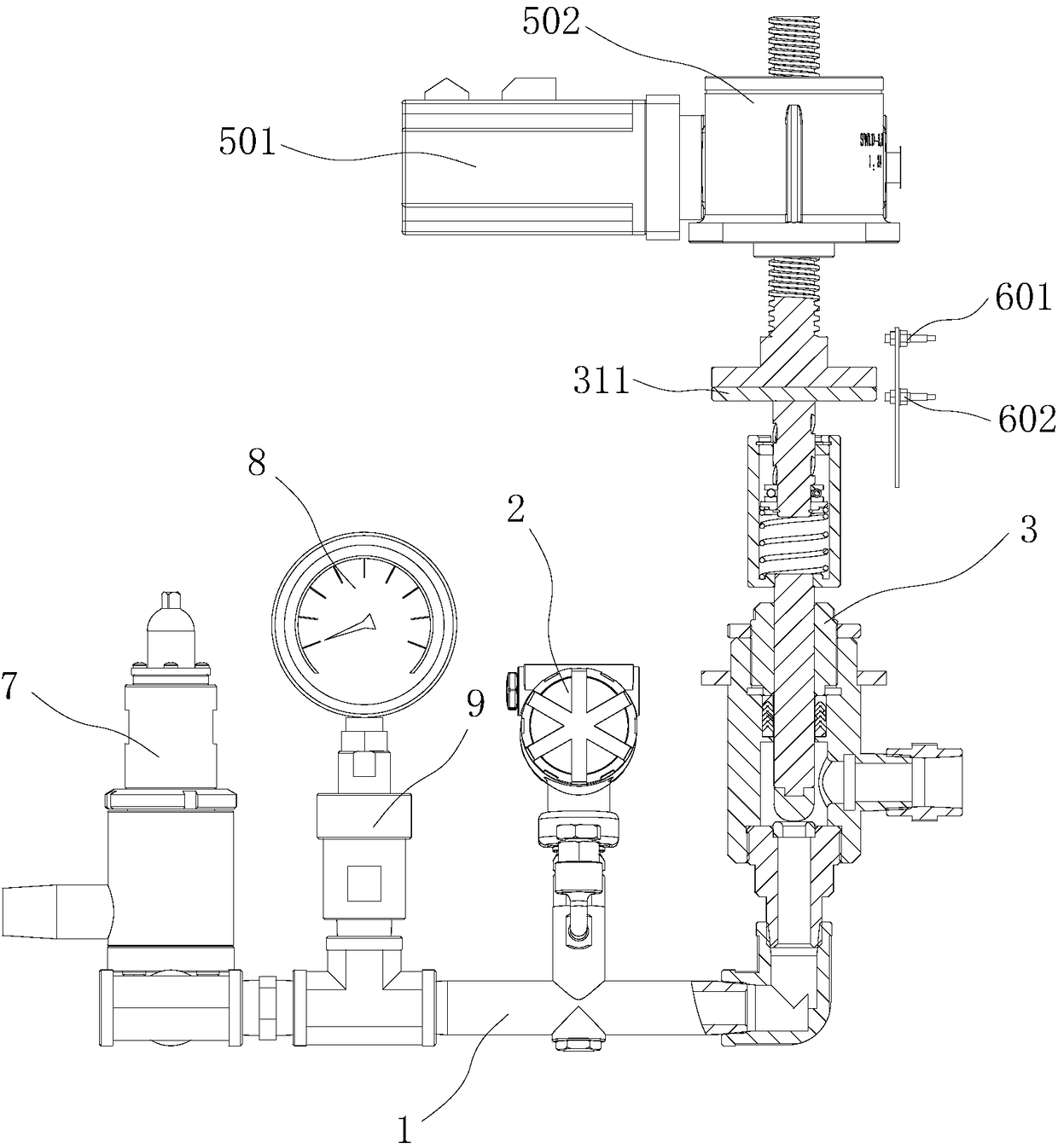

[0026] Such as Figure 1 to Figure 3 As shown, this embodiment provides a grouting pressure control device, including a pressure sensor 2 and a high-pressure valve 3 arranged on the grouting pipeline 1 along the flow direction of the grouting material. The pressure sensor 2 is electrically connected to a control unit 4, and the high-pressure The valve 3 is connected to the power unit, and the power unit is electrically connected to the control unit 4 .

[0027] The pressure sensor 2 is used to monitor the real-time pressure of the grouting pipeline 1 and transmit the real-time data to the control unit 4 . The high-pressure valve 3 is the terminal actuator of the grouting pressure control device, and the pressure of the grouting system can be changed by changing the opening size of the high-pressure valve 3 . The power unit is used to control the opening size of the high pressure valve 3 .

[0028] The grouting pressure control device monitors the pressure change in the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com